Assembled artificial floating bridge system

A prefabricated and artificial technology, applied in pontoon bridges, bridges, bridge parts, etc., can solve the problems of severe wear of positioning piles and floating bridges, low strength of foam materials, easy deflection of positioning piles, etc. The degree of wear, the effect of improving the drilling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

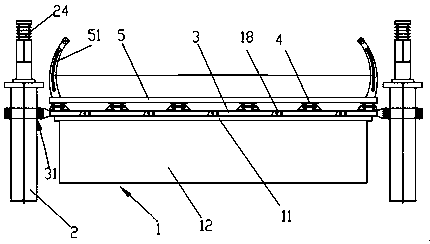

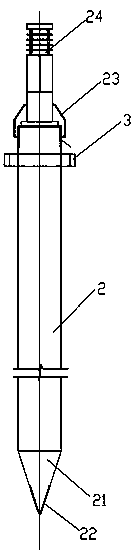

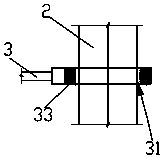

[0038] Such as Figure 1-8 As shown, the present invention discloses an assembled artificial pontoon system, comprising a floating tank 1, a positioning pile 2, a beam 3, a longitudinal beam 4 and a sidewalk slab 5, the two ends of the beam 3 are provided with socket holes 31, and the positioning pile 2 Inserted in the socket hole 31, the crossbeam 3 is detachably installed on the buoyancy tank 1, the longitudinal beam 4 is detachably installed on the crossbeam 3 and vertically arranged relative to the crossbeam 3, and the sidewalk board 5 is vertically laid on the longitudinal beam 4. The pontoon system has a simple structure and is easy to install. All components can be prefabricated in the factory and installed directly on site, which not only sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com