Laminated magneto-rheological vibration isolation support based on transmission lifting device

A vibration isolation bearing and lifting device technology, applied in bridge parts, bridge materials, bridges, etc., can solve the problems of weak shear force action ability, complex lifting structure, poor vertical stiffness, etc., and achieve good compressive performance, Improved isolation performance, improved damping and stiffness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

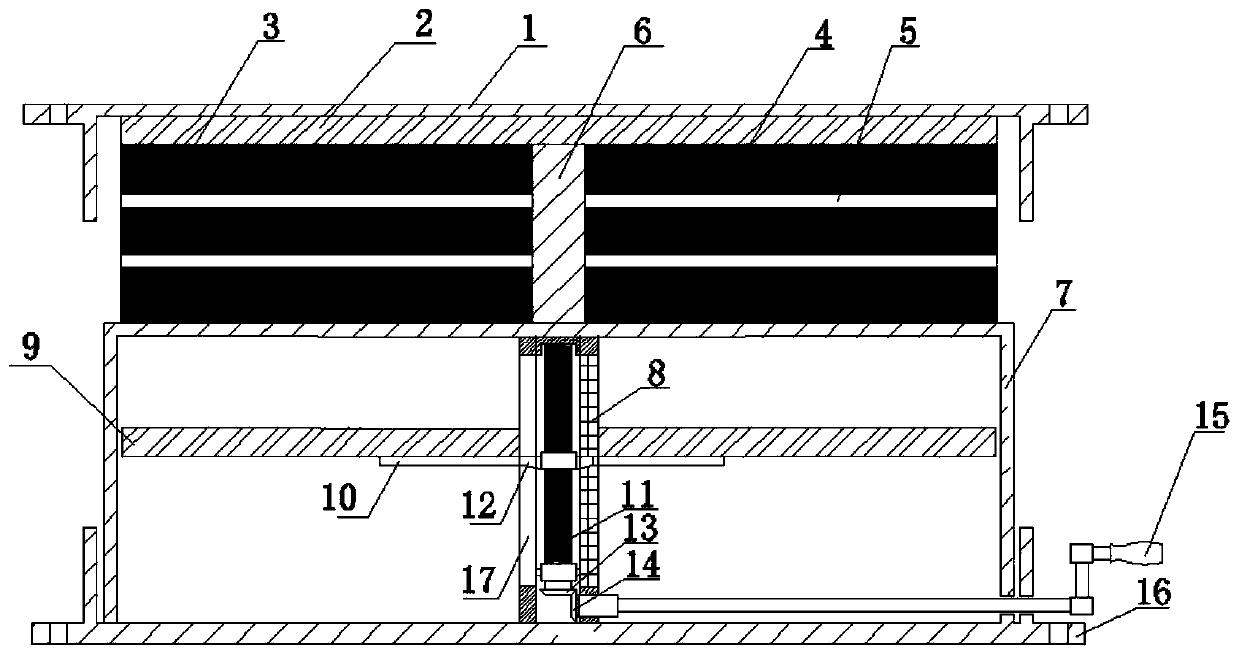

[0037] Such as figure 1 As shown, the laminated magnetorheological vibration isolation support based on the transmission lifting device provided by the present invention includes an upper steel plate 1, a lower steel plate 16, an upper permanent magnet 2, a lower permanent magnet 9, a laminated support mechanism 3, a lead The core 6, the lower support shell 7 and the lifting device; the upper permanent magnet 2 is adsorbed on the bottom of the upper steel plate 1; the laminate support mechanism 3 is connected with the upper permanent magnet 2 and the lower support shell 7; the laminate support machine 3 adopts Damping magnetorheological elastomer-steel plate vulcanized lamination, the lower supporting shell 7 is connected to the lower steel plate 16 of the support; the lifting device includes a sleeve 8, a circular lifting platform 10, a connecting plate 12, a screw 11, a transverse Gear 13, vertical gear 14 and hand crank 15; Sleeve 8 is fixedly connected with lower steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com