Maintenance system of large-water-depth bucket type stilling pool and implementation method

A stilling pool, large water depth technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve problems such as the size cannot be too large, structural piers and flap doors are easily damaged and deformed, and maintenance is difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

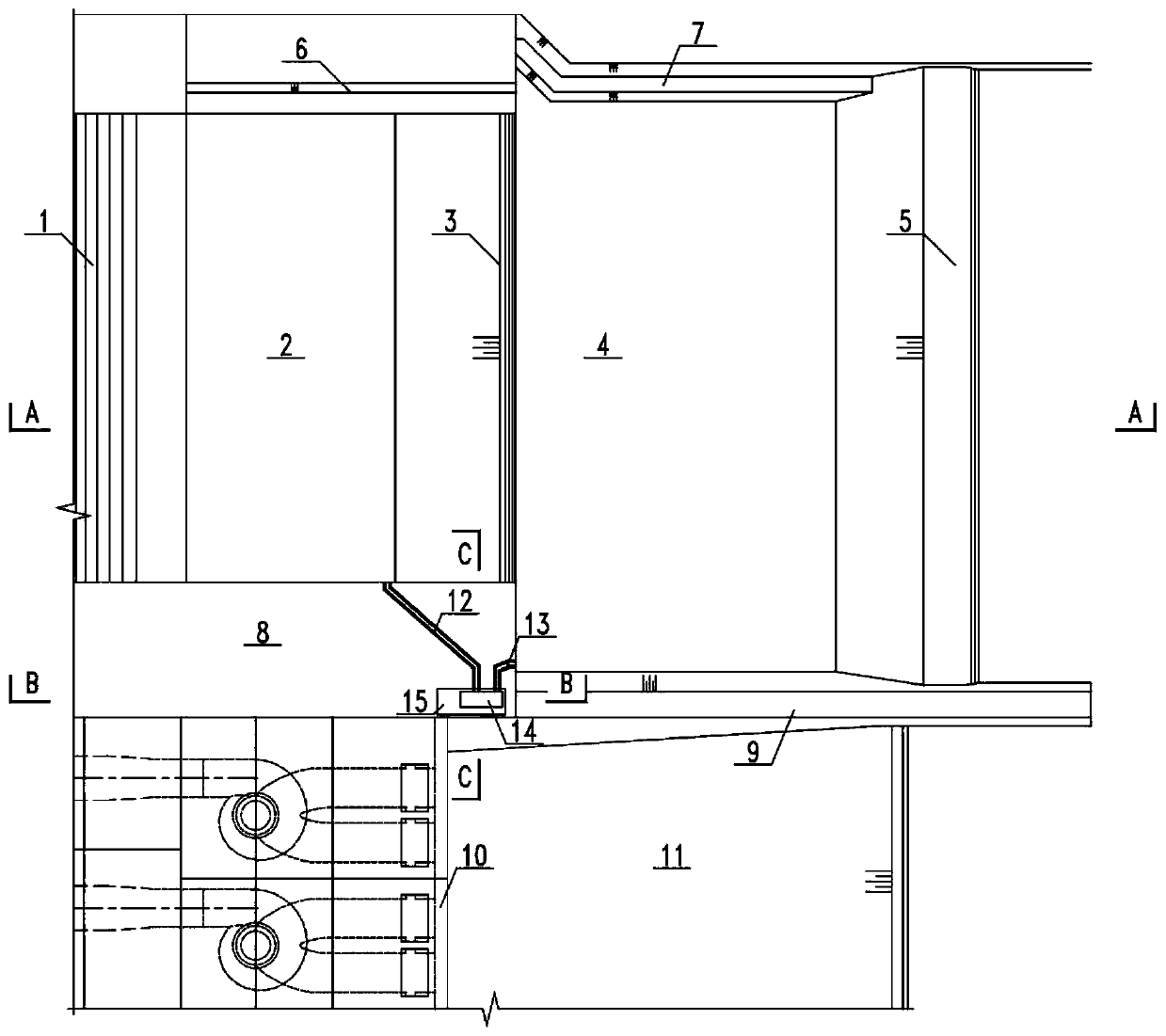

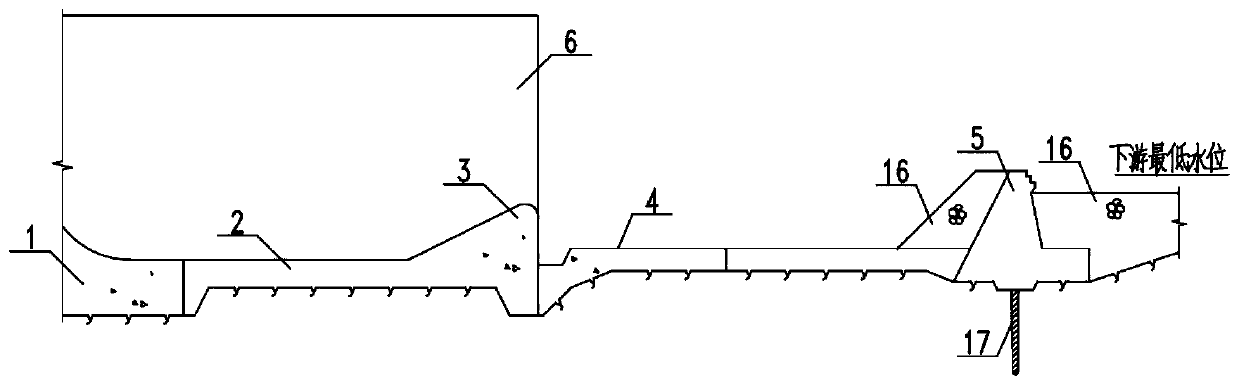

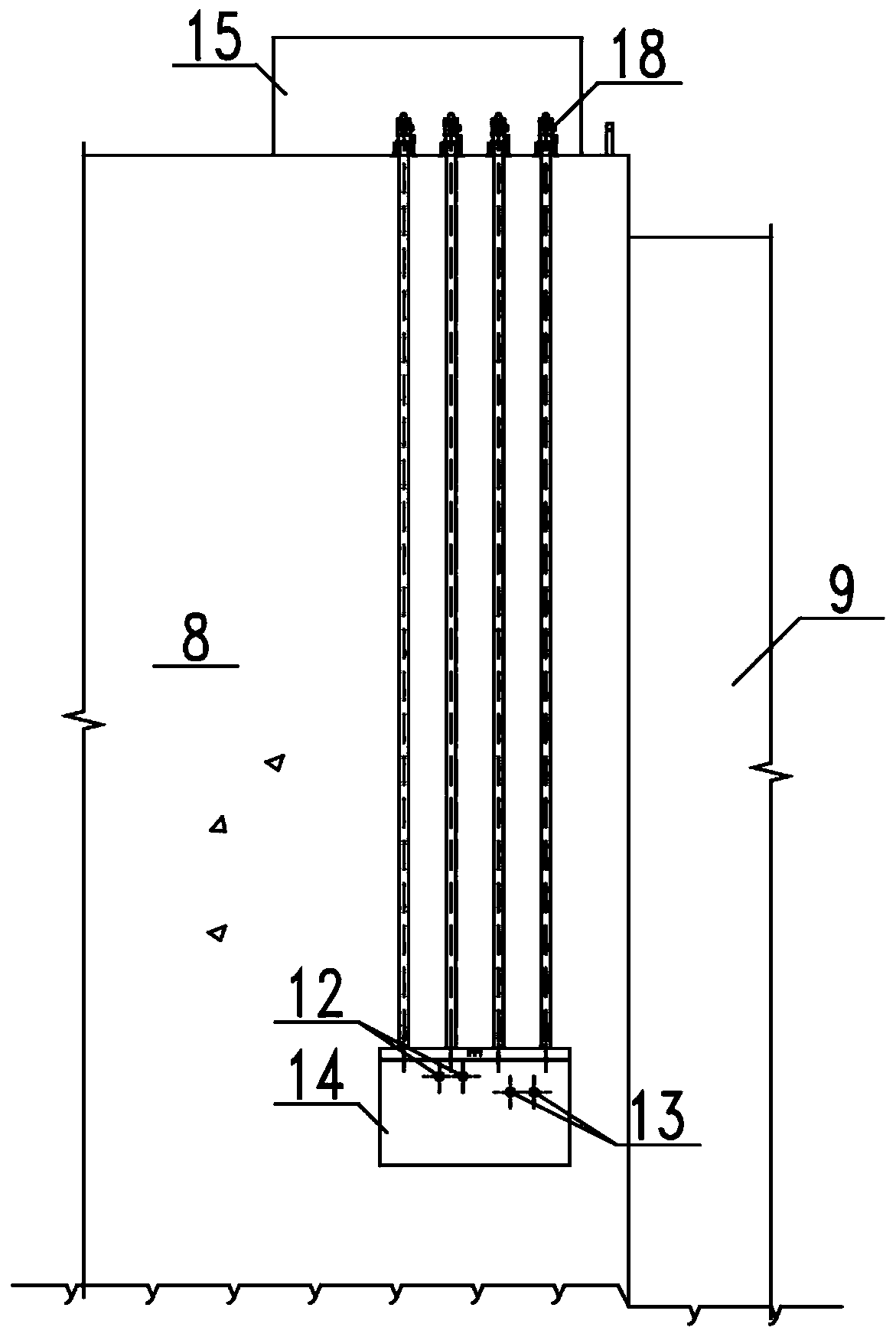

[0024] A maintenance system for a large water deep stilling basin, comprising an overflow dam section dam body 1, a stilling basin 2 downstream of the overflow dam section dam body 2, and a stilling basin sill at the tail of the stilling basin 2 3. An apron 4 is provided downstream of the stilling basin 2, and an inspection cofferdam core wall 5 is provided at the tail of the apron 4. The top elevation of the inspection cofferdam core wall 5 is slightly higher than the lowest tail water level downstream; the stilling basin 2 On the side close to the bank slope, there is a stilling basin side wall 6, downstream of the stilling basin side wall 6, and the side of the apron 4 close to the bank slope is a rocky side slope 7; There is a powerhouse dam section 10 on one side of the river bed, a powerhouse tailrace 11 is arranged downstream of the powerho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com