Modular rapid construction method for structure-beam steel bar skeleton of deep foundation pit

A technology of steel skeleton and construction method, applied in basic structure engineering, excavation, geometric CAD, etc., can solve the problem of difficult control of steel spacing, protective layer, steel connection accuracy, inability to quickly complete the concrete pouring of the bottom plate, and prolong the exposure time of the foundation pit, etc. problems, to achieve good social and economic benefits, shorten the construction period, and achieve the effect of rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention will be further described. Apparently, the described embodiments are some, but not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

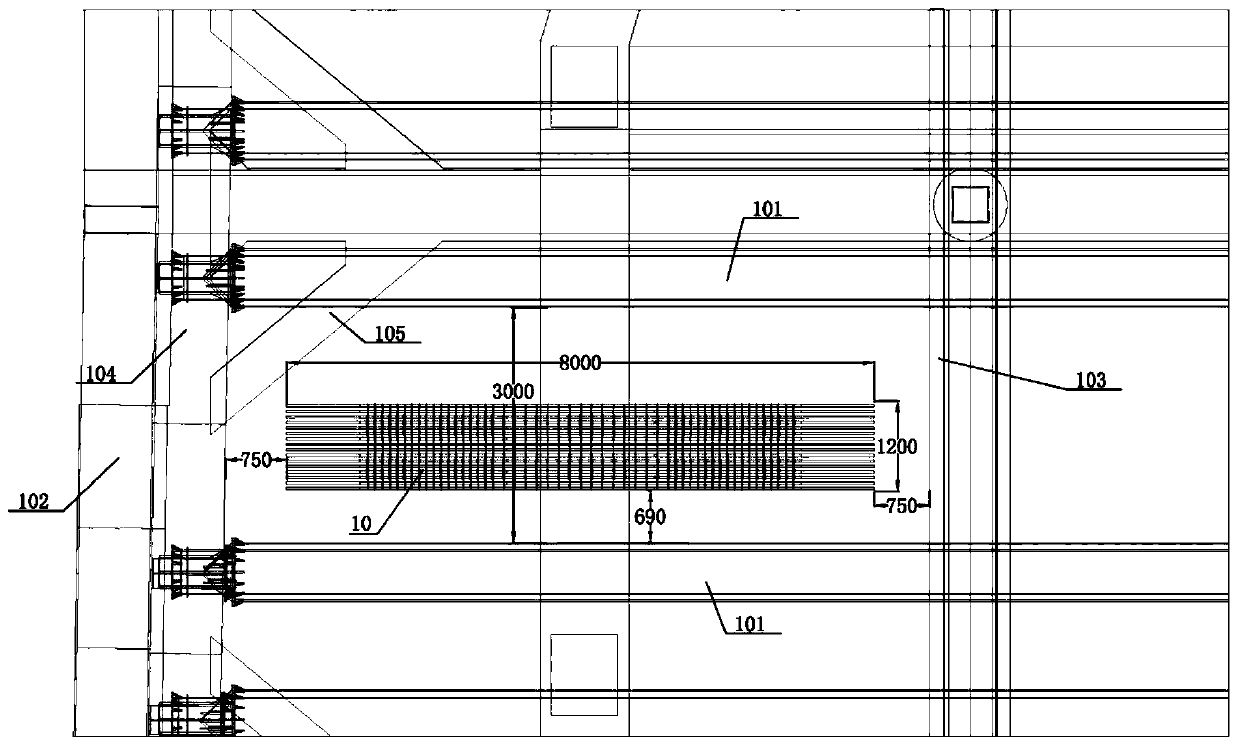

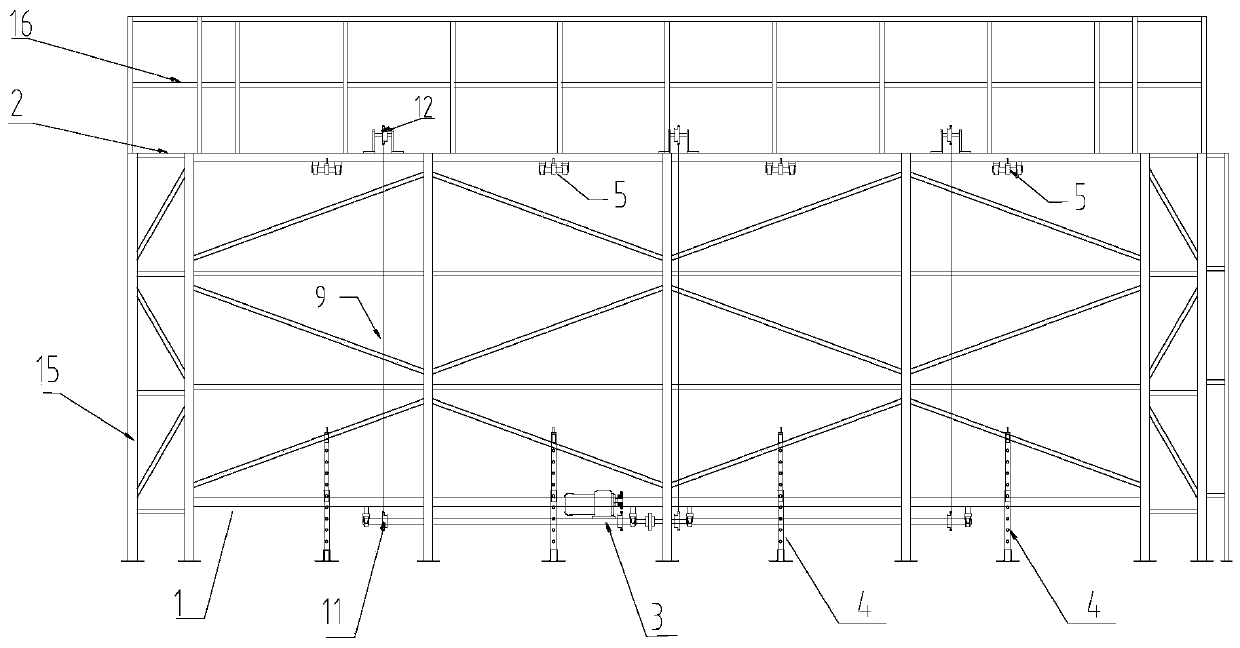

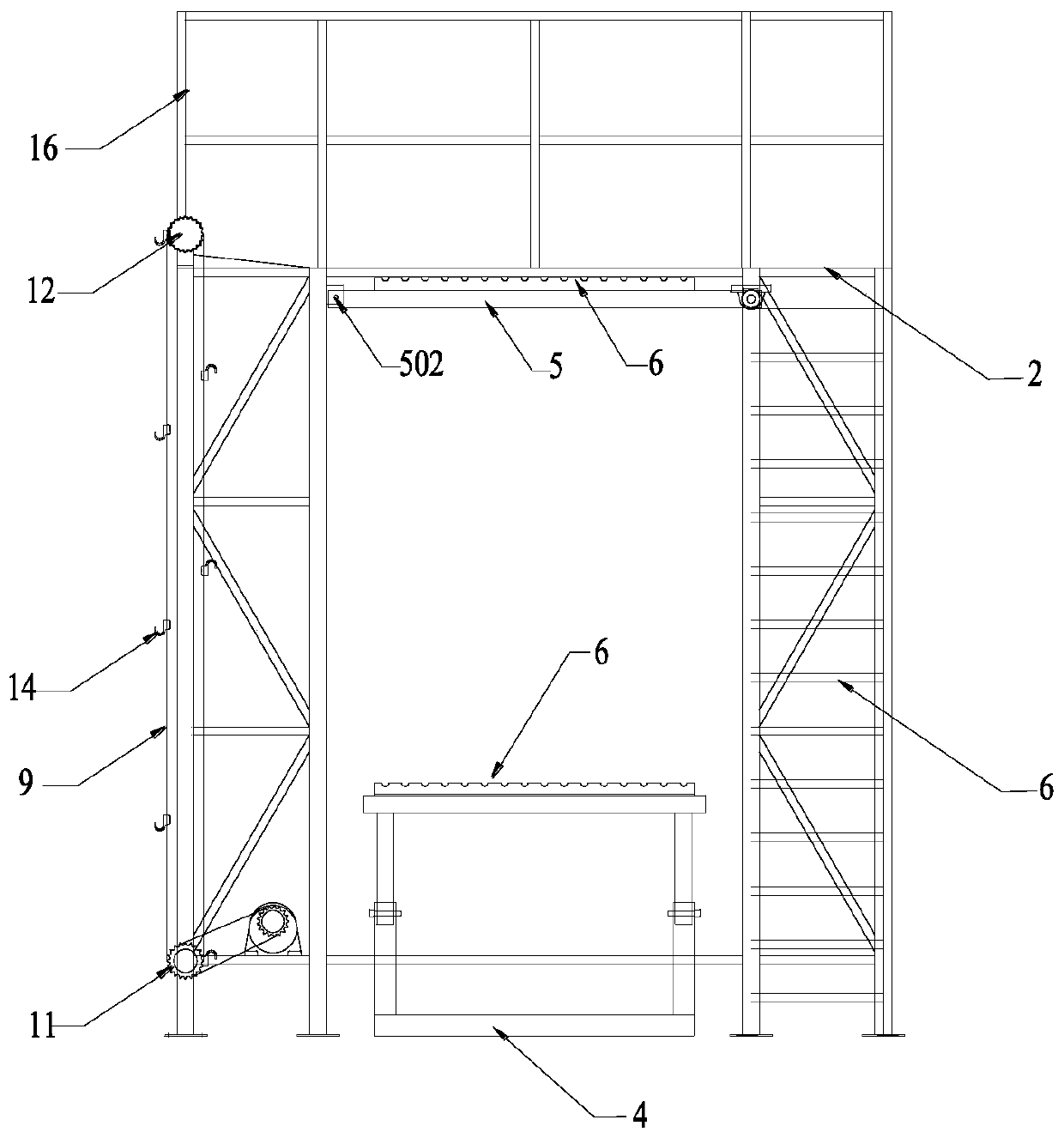

[0029] Project background: Hangzhou-Haining intercity railway project is the first batch of PPP demonstration projects in Zhejiang Province. Yuhang high-speed railway station is the largest underground three-story station on the whole line. The total length of the main foundation pit outsourcing is 458m, the standard section width is 22.1m, and the maximum excavation depth is 30m , set up eight layers of internal support, and the safety level is level one. The surrounding environment of the main foundation pit is complex. The east side of the foundation pit of the station is close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com