High-molecular self-adhesive waterproof coiled material wet laying process

A self-adhesive waterproof membrane and polymer technology, which is used in infrastructure engineering, building insulation materials, roofing using flexible materials, etc., can solve the problems of waterproof failure of lap joints and leakage of waterproof membranes, and shorten the construction period. , The effect of reliable bonding and high degree of freedom of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

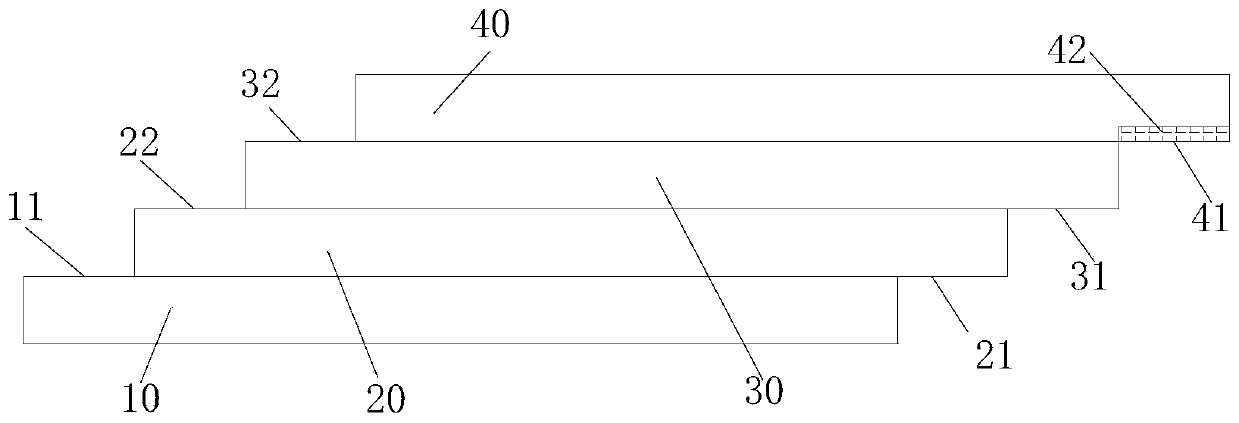

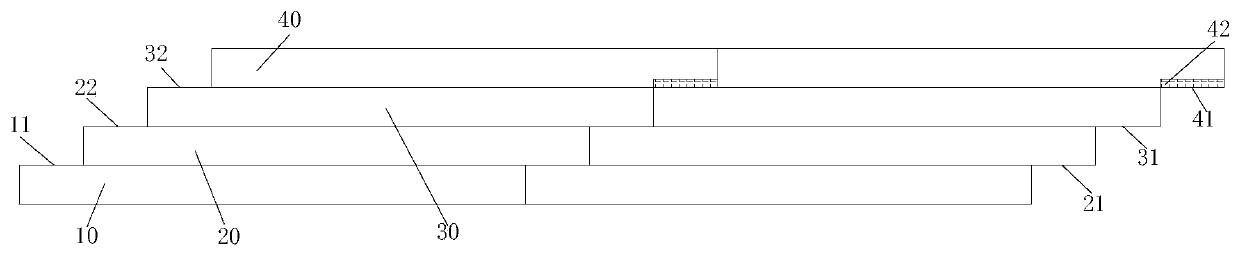

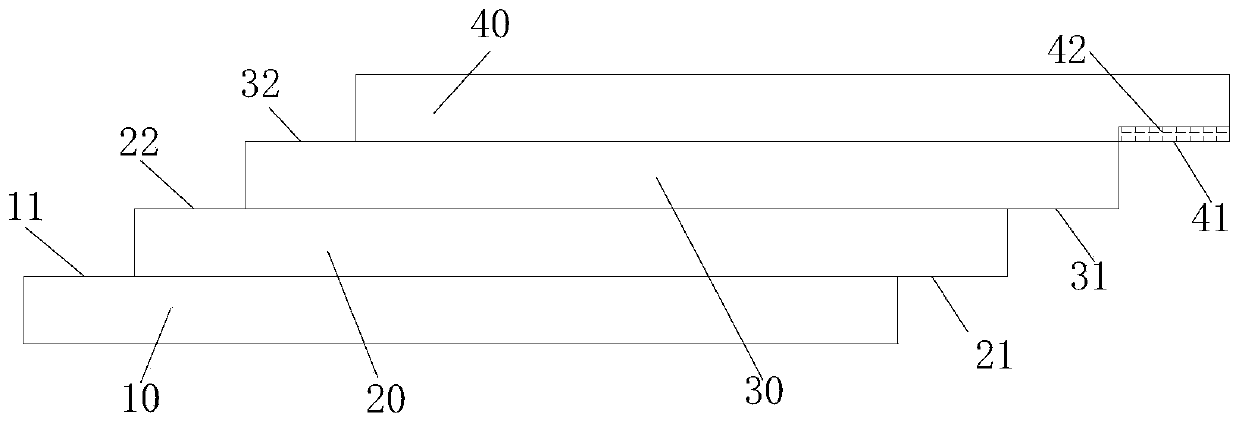

[0042] Please see figure 1 and figure 2 , a polymer self-adhesive waterproof membrane wet-laying process provided in the embodiment of the present application, comprising the following steps:

[0043] Include the following steps:

[0044] S1: Clean the surface of the base layer and fully wet the base layer, but there should be no clear water;

[0045] S2: laying a layer of hot-melt pressure-sensitive adhesive film on the surface of the base;

[0046] S3: Lay the first coil on the hot-melt pressure-sensitive adhesive film;

[0047] S41: after the laying of the first coil is completed, respectively uncover the isolation films of the third lap, the fifth lap and the sixth lap on the first coil;

[0048] S42: Uncover the separation film of the first lap, the second lap and the fourth lap on the second coil;

[0049] S43: The first overlapping edge of the second coil is overlapped with the third overlapping edge of the first coil; the second overlapping edge of the second coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com