Destructive camshaft structural strength comprehensive detection system and use method

A technology for comprehensive detection and structural strength, applied in the field of comprehensive detection system for destructive camshaft structural strength, can solve the problems of detection equipment storage, poor use flexibility and convenience, low detection accuracy, and high work labor intensity, etc., to achieve structural strength. The effects of good stability and versatility, high modularity and intelligence, and high degree of operation automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

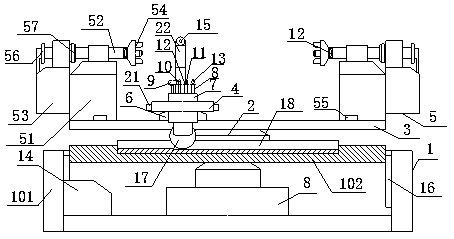

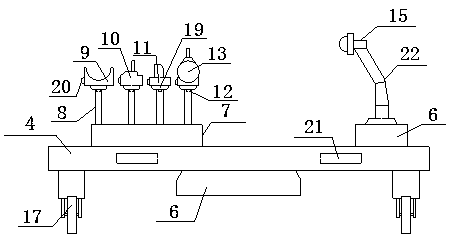

[0028] Such as figure 1 with 2 A comprehensive detection system for the structural strength of a destructive camshaft is shown, including a bearing frame 1, a turntable mechanism 2, a main driving guide rail 3, an auxiliary driving guide rail 4, a bearing positioning seat 5, a bearing block 6, a slider 7, and a lifting drive mechanism 8. Bearing bush 9, hardness tester 10, hard alloy stopper 11, pressure sensor 12, dial gauge 13 and control system 14, the bearing frame 1 is a frame structure with a rectangular cross section, its axis is vertically distributed to the horizontal plane, and the turntable The mechanism 2 is connected with the upper end surface of the bearing frame 1 and distributed coaxially, the lower end surface of the main driving guide rail 3 is connected with the upper end surface of the bearing frame 1 through the turntable mechanism 2, and the main driving guide rail 3 is distributed parallel to the axis of the upper end surface of the bearing frame 1, The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com