Method for determining storage time of battery cells

A technology for storing time and cells, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of long shelving time, a large number of batteries, and increase the cost of batteries, and achieve a reasonably certain effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

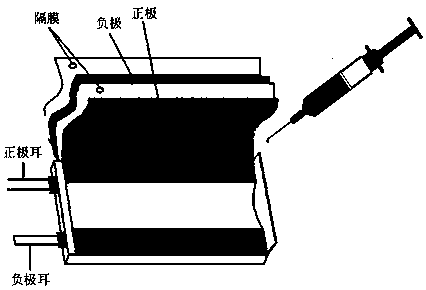

[0023] A method for determining the battery cell storage time, the steps are as follows:

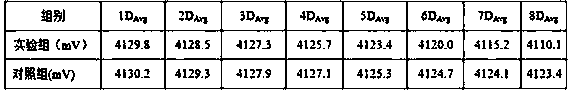

[0024] Select metal Fe debris, filter it with a 200-mesh sieve, and remove the filtered material (ie seeds) in the lower layer for use. Divide the batteries that have not been filled with liquid after baking into two groups, namely the experimental group and the control group. core, add NMP solvent to the positive electrode sheet on the outer layer of the battery cell, and then inoculate a seed of metal debris. The moisture and NMP introduced during the operation, after normal pre-charging of the battery cells, were stored at a temperature of 25±2°C, and the daily voltage changes before and after storage were compared between the experimental group and the control group, as shown in Table 1 below, and the control group and the control group were recorded. When the pressure difference of the experimental group is greater than 5mV, the time required for the battery cell is 7D, which is the...

Embodiment 2

[0028] A method for determining the battery cell storage time, the steps are as follows:

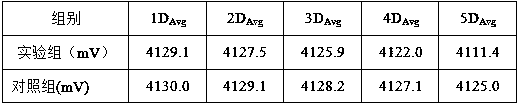

[0029] Select metal FeS debris, filter it with a 200-mesh sieve, and remove the filtered material (ie seeds) in the lower layer for use. Divide the batteries that have not been filled with liquid after baking into two groups, namely the experimental group and the control group. core, add NMP solvent to the positive electrode sheet on the outer layer of the battery cell, and then inoculate 5 metal debris seeds. The moisture and NMP introduced during the operation, after the battery is pre-charged normally, it is stored at a temperature of 25±2°C, and the daily voltage changes before and after storage are compared between the experimental group and the control group, as shown in Table 2 below, and the control group and the control group are recorded. When the pressure difference of the experimental group is greater than 5mV, the time required for the battery cell is 4D, which is the storag...

Embodiment 3

[0033] A method for determining the battery cell storage time, the steps are as follows:

[0034] Select the metal S304 debris, filter it with a 100-mesh sieve, and remove the filtered material (ie seeds) in the lower layer for use. Divide the batteries that have not been filled with liquid after baking into two groups, namely the experimental group and the control group. core, add NMP solvent to the positive electrode sheet on the outer layer of the battery, and then inoculate 1 metal debris seed. After the NMP volatilizes and restore the original appearance of the battery, place the experimental group and the control group in an environment of 55 ° C, bake for 16 hours, remove The water and NMP introduced during the operation, after the battery is pre-charged normally, store it at a temperature of 25±2°C, compare the daily voltage changes before and after storage in the experimental group and the control group, as shown in Table 3 below, record the control group and the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com