Press-fitting control system and method

A control system and control device technology, which is applied in general control systems, control/regulation systems, sequence/logic controller program control, etc., can solve the problem of small amount of read data, inflexible information configuration process, and information content Quantity limitations and other issues, to achieve the effect of increased data sampling frequency, humanized human-computer interaction, and strong data collection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The invention discloses a press-fit control system and a press-fit control method, specifically as follows.

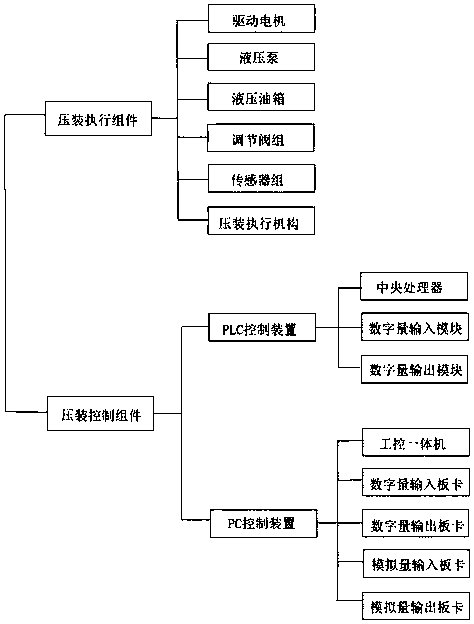

[0054] Such as figure 1 As shown, a press-installation control system includes a press-installation executive assembly and a press-installation control assembly, the press-installation control assembly is connected with the press-installation executive assembly, and is used to control the operation of the press-installation executive assembly. The press-fit control assembly includes a PLC control device and a PC control device, and the PLC control device is connected to the PC control device.

[0055] The PLC control device is used for the preparation before the pressing action, including:

[0056] The central processing unit is connected to the PC control device through its own Ethernet communication interface and realizes data interaction, and is used to record and execute the press-fitting logic program and realize the system action control before the press-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com