Structure and method for measuring precision of high-speed comparator based on TDC chip

A high-speed comparator and chip technology, applied in the direction of pulse processing, electrical components, pulse technology, etc., can solve the problems of unable to automate testing, batch automation, and high frequency requirements of input signals, so that it is not easy to trigger false trigger comparison, realize accuracy, and measure high resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Attached below Figure 4-6 , the specific embodiment of the present invention will be further described in detail.

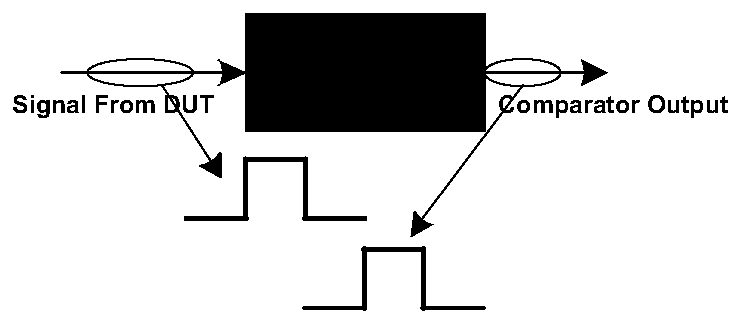

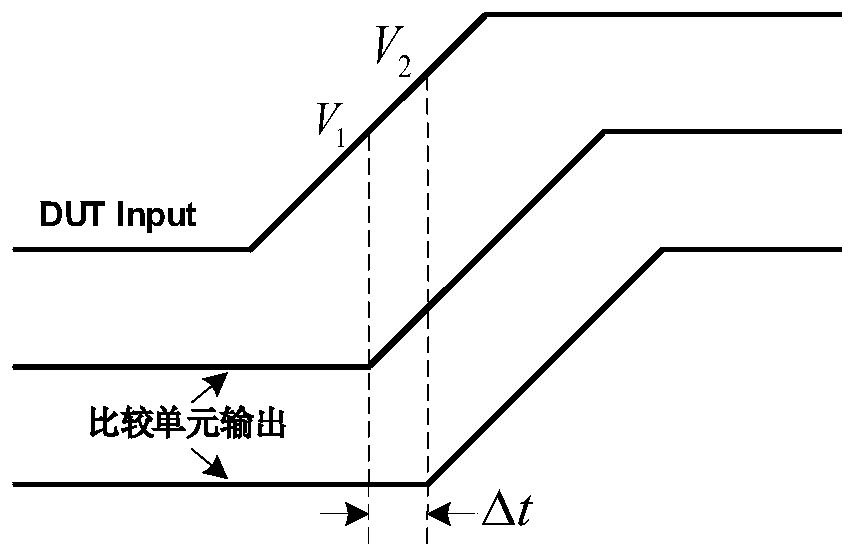

[0075] see Figure 4 , Figure 4 It is a block schematic diagram of a preferred embodiment of the structure of the present invention based on the TDC (Time-Digital Converter) chip to measure the precision of the high-speed comparator. As shown in the figure, in addition to the high-speed comparator to be tested, the structure may include a signal generation module, a control module and a TDC chip module; wherein, the signal generation module generates a set of N pulse signals, square wave signals or sawtooth wave signals, In some other embodiments of the present invention, the signal generator can generate a group of N pulse signals, square wave signals or sawtooth wave signals under the control of the control module; wherein, N is a positive integer greater than or equal to 2.

[0076] The same as the voltage test method in the prior art, the positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com