Waveguide fed microwave coupled plasma generator

A technology for coupling plasma and generating devices, applied in the direction of plasma and electrical components, can solve problems such as deformation of PTFE supports, burning of microwave antennas, overheating of microwave antennas, etc., and achieve uniform distribution of the overall electromagnetic field and coupling of microwave energy High efficiency, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

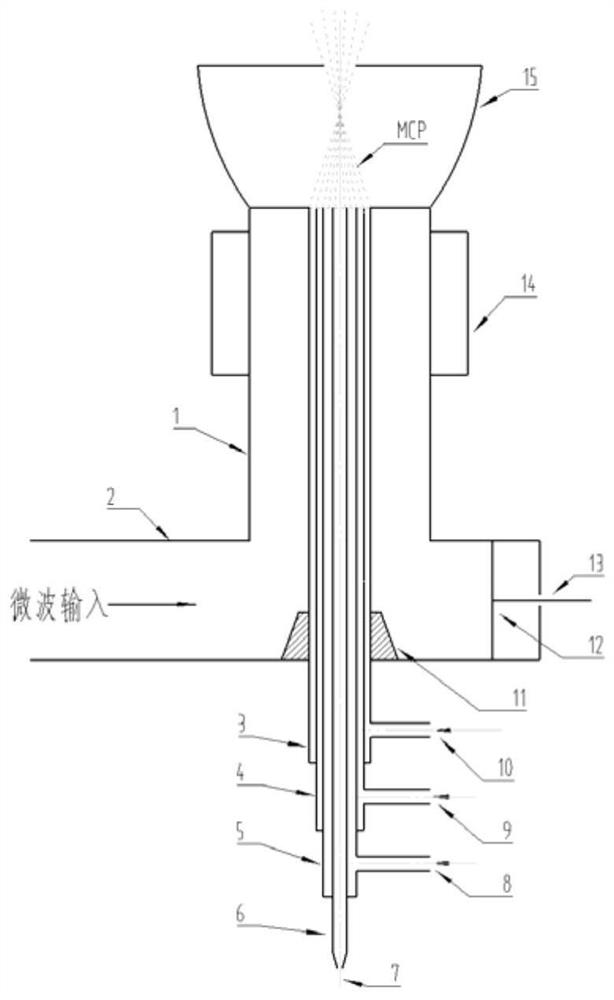

[0035] see figure 1 , a waveguide-feeding type MCP generating device, the generating device is mainly composed of a waveguide part and a coaxial resonant cavity part.

[0036] The waveguide part includes a standard waveguide 2 , a waveguide-coaxial conversion cone 11 , a short-circuit piston 12 and an adjustment rod 13 .

[0037] The first port of the standard waveguide 2 is connected to the microwave generation system, and the coaxial resonant cavity outer conductor 1 is vertically installed on the upper outer wall in the length direction between the first port and the second port of the standard waveguide 2, and the lower inner wall in the length direction of the standard waveguide 2 The waveguide-to-coaxial conversion cone 11 is installed, and the central axis of the cone coincides with the central axis of the outer conductor 1 . The second port corresponding to the first port of the standard waveguide 2 is closed by the short-circuit piston 12, and the short-circuit pisto...

Embodiment 2

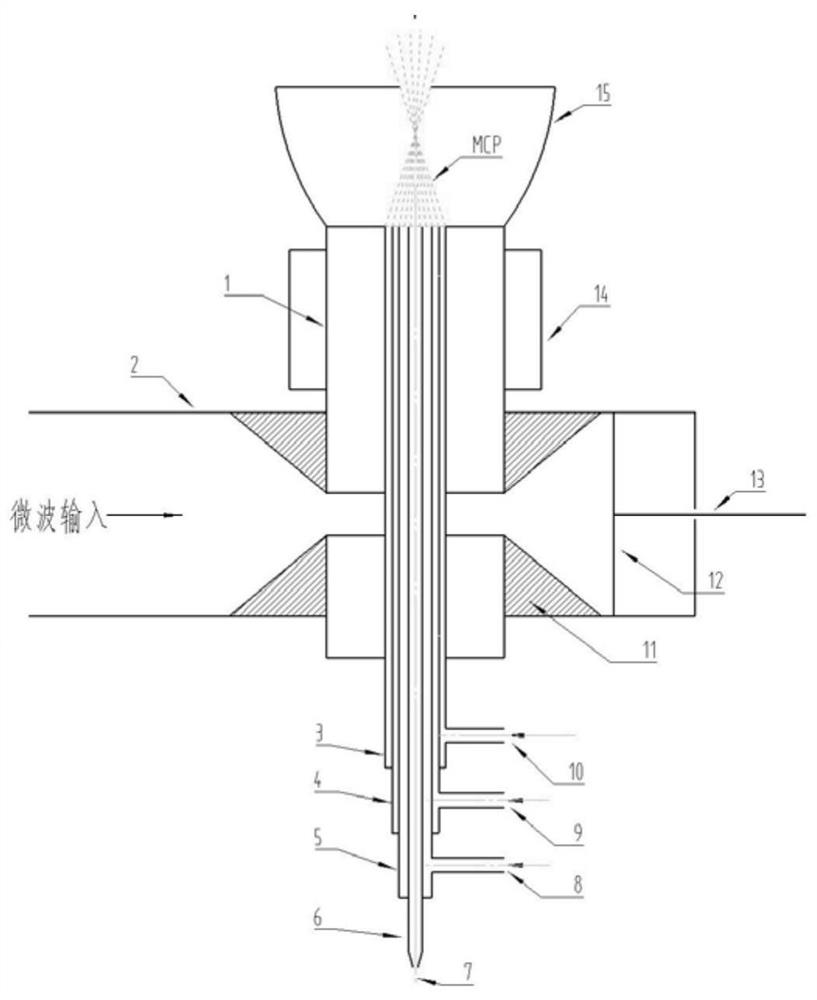

[0063] see figure 2 , the generating device is mainly composed of a waveguide part and a coaxial resonant cavity part.

[0064] The waveguide part includes a standard waveguide 2 , a waveguide-coaxial conversion cone 11 , a short-circuit piston 12 and an adjustment rod 13 . Wherein, the standard waveguide 2 , the short-circuit piston 12 and the adjusting rod 13 are completely the same as those in the first embodiment, and only the waveguide-coaxial conversion cone 11 is different from the first embodiment.

[0065] The waveguide-to-coaxial conversion cone 11 is two components with the same size, which are installed on the upper and lower sides of the inner wall of the standard waveguide 2 respectively, and the central axis of the cone coincides with the central axis of the outer conductor 1 . The cone can be a truncated cone, preferably, the angle of the cone is 40 degrees; it can also be a symmetrical trapezoid, preferably, the angle of the trapezoid is 40 degrees.

[0066...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com