Cosmetic packaging blister film and forming production line thereof

A technology for blister film and cosmetics, applied in the field of cosmetic packaging film production equipment, can solve the problems of lack of positioning structure, affecting the production efficiency of blister film, prone to collapse, etc., to ensure neatness, not easy to collapse, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

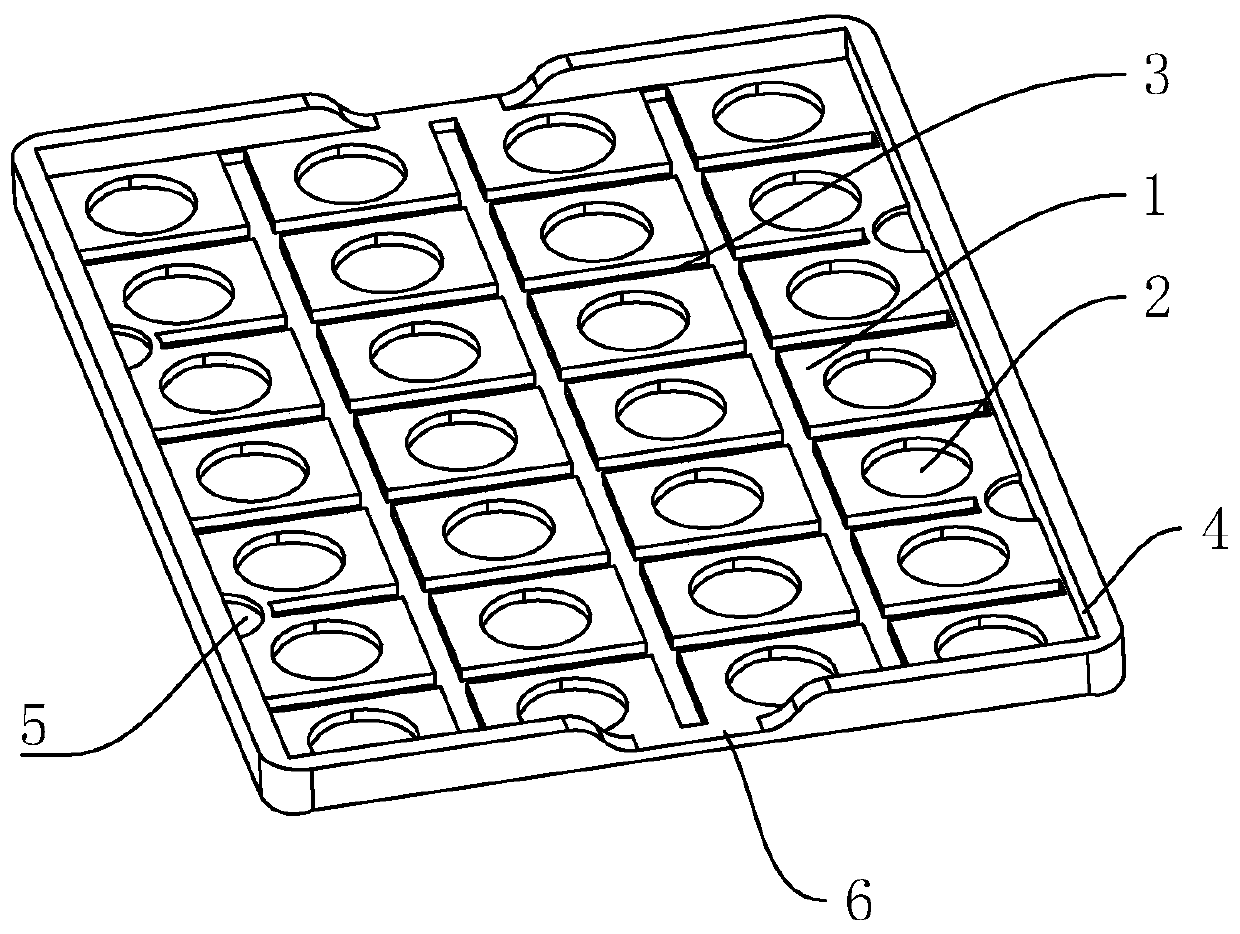

[0041] Embodiment: a kind of cosmetic packaging blister film, such as figure 1 As shown, the plastic film body 1 is included, and the plastic film body 1 is provided with a plurality of accommodating cavities 2, which are equidistantly distributed. 2 is provided with a first positioning card slot 3, the first positioning card slot 3 is set in a concave shape, the edge of the plastic film body 1 is provided with a ring-shaped card slot 4, and a second positioning card slot 4 is opened in the ring-shaped card slot 4 The card slot 5, when the adjacent plastic film bodies 1 are stacked together, the first positioning card slot 3 and the second positioning card slot 5 can be engaged with each other, so that the adjacent plastic film bodies 1 can be stacked When it is more stable, it is not easy to collapse.

[0042] like figure 1 As shown, the plastic film body 1 is provided with an arc-shaped notch 6 on both sides along the length direction, and the edge of the arc-shaped notch ...

specific Embodiment approach

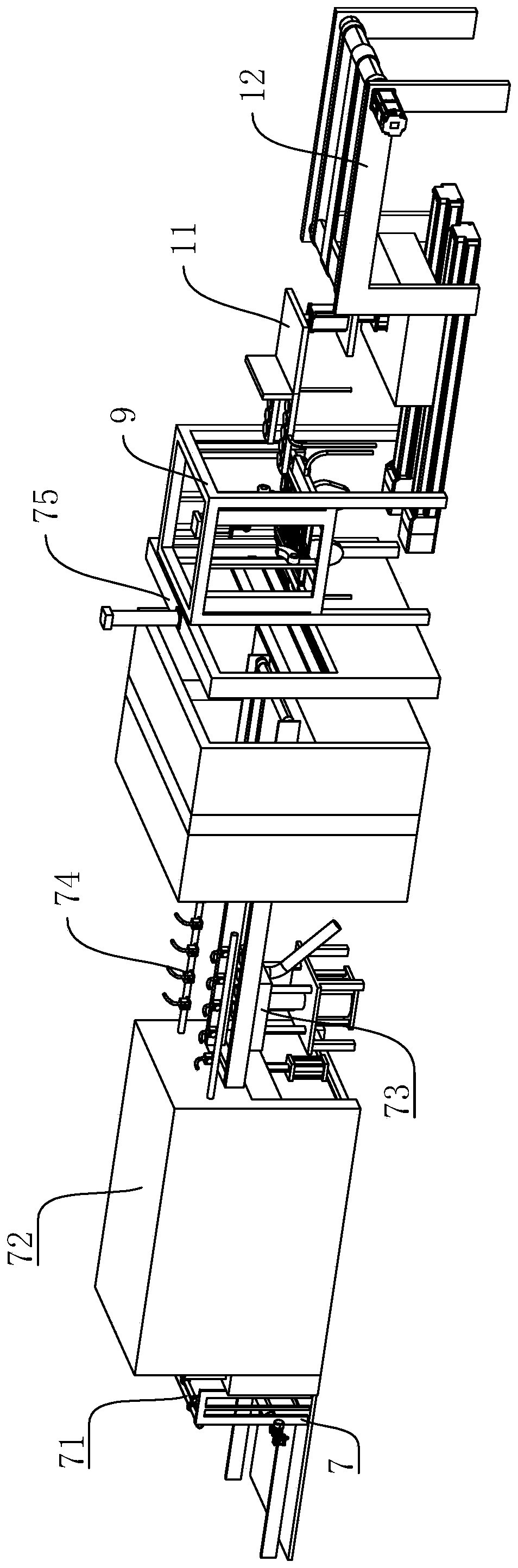

[0062] Specific embodiments: the PS material strip is transported to the feeding device 71 , and the heating device 72 can heat and soften the material strip during the transmission process of the material strip. The material strip after softening enters in the plastic-absorbing device 73, and the mold matching with the plastic-absorbing film body 1 is arranged in the plastic-absorbing device 73, and the lower end of the mold is provided with a vacuum pump, and the vacuum pump is started to make the vacuum pump absorb the softened material belt , so that the tape can fit the mold.

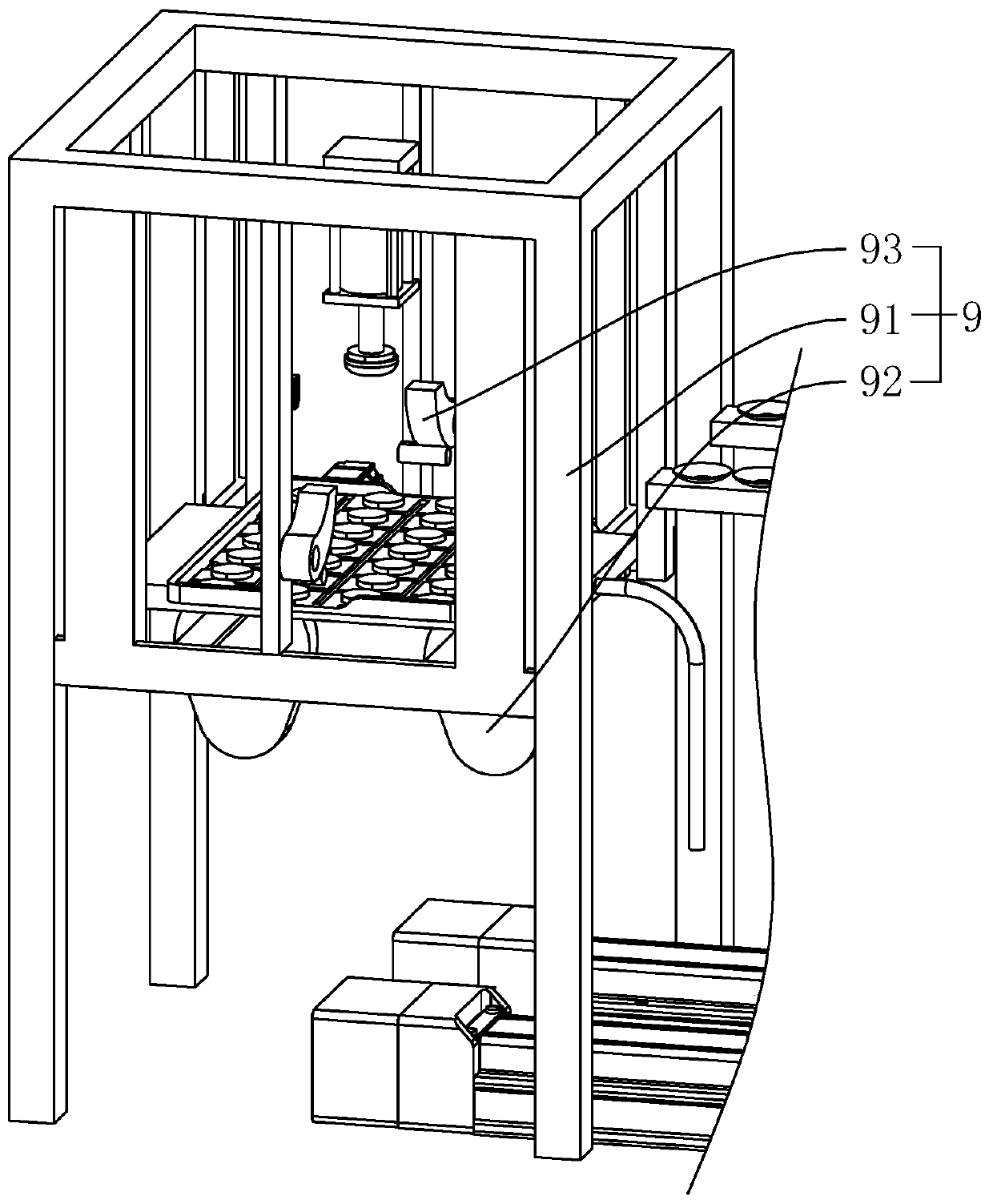

[0063] During the process of plastic absorption, the cooling device 74 sprays cooling water on the top of the material belt, and at the same time, the cooling air flow acts on the material belt, so that the material belt can be cooled rapidly during the process of plastic absorption, and the plastic film after cooling and forming continues to move , the cutting knife in the cutting device 75 can cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com