Nylon brush wire product and manufacturing method thereof

A nylon brush wire and a manufacturing method technology, applied in the field of nylon products, can solve the problems of weakening the oxidation resistance and wear resistance of nylon brush products, shortening the service life of nylon brush products, and low brush hardness and tensile strength. , to avoid oxidative deterioration, reduce friction coefficient, improve brush hardness and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The nylon brush filament product includes the following raw materials and their weight fractions: 55 parts by mass of nylon; 25 parts by mass of abrasive; and 3 parts by mass of coupling agent.

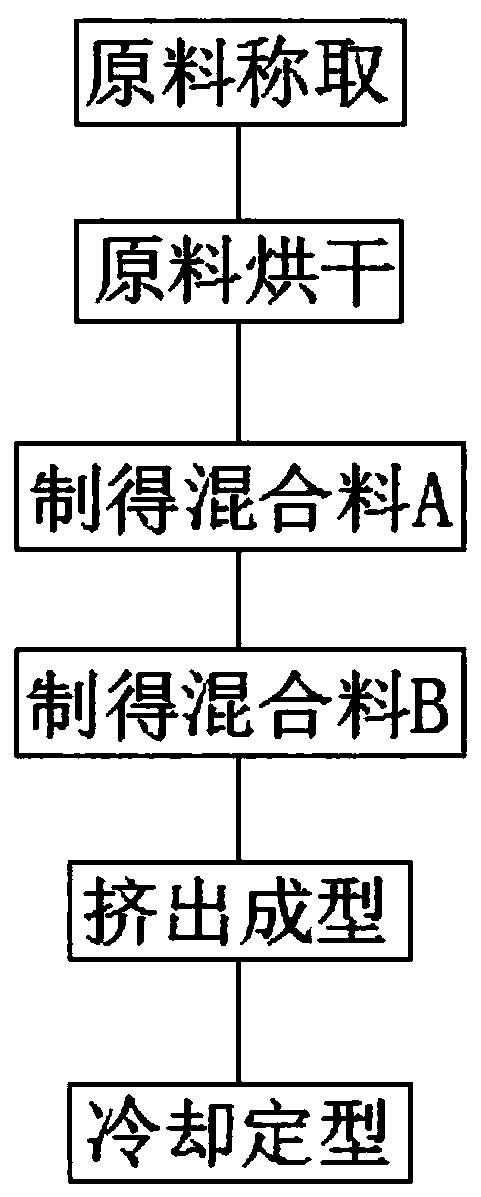

[0047] The manufacturing steps are as follows:

[0048] a. Weigh the above raw materials in parts by weight;

[0049] b. After step a is completed, put the weighed raw materials into the oven for drying;

[0050] c. After step b is completed, add the coupling agent to the diluent to dilute, and then put the dried abrasive and the diluted coupling agent into the mixer for mixing, to obtain a mixture A;

[0051] d. After step c is completed, add nylon, solid lubricating anti-wear agent, antioxidant, and mixture A together into the mixer for mixing to obtain mixture B;

[0052] e. After step d is completed, put the mixture B into the extruder for extrusion molding;

[0053] f. After step e is completed, put the extruded monofilament into a water tank to cool and shape, and then separate the f...

Embodiment 2

[0056] The nylon brush filament product includes the following raw materials and their weight fractions: 55 parts by mass of nylon; 25 parts by mass of abrasive; 3 parts by mass of coupling agent; 4 parts by mass of solid lubricating and anti-wear agent; Mass parts.

[0057] The manufacturing steps are as follows:

[0058] a. Weigh the above raw materials in parts by weight;

[0059] b. After step a is completed, put the weighed raw materials into the oven for drying;

[0060] c. After step b is completed, add the coupling agent to the diluent for dilution, and then put the dried abrasive and the diluted coupling agent into the mixer for mixing, to obtain a mixture A;

[0061] d. After step c is completed, add nylon, solid lubricating anti-wear agent, antioxidant, and mixture A together into the mixer for mixing to obtain mixture B;

[0062] e. After step d is completed, put the mixture B into the extruder for extrusion molding;

[0063] f. After step e is completed, put the extruded mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com