Gas-charging ceramic treatment frame for fabrics

A technology of inflatable fabrics and ceramics, applied in physical treatment, fiber treatment, ultrasonic/sonic fiber treatment, etc., can solve the problems of poor sealing, poor cooling performance, irregular corona treatment of fabrics, etc., to reduce tension and normal surface stress. , the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

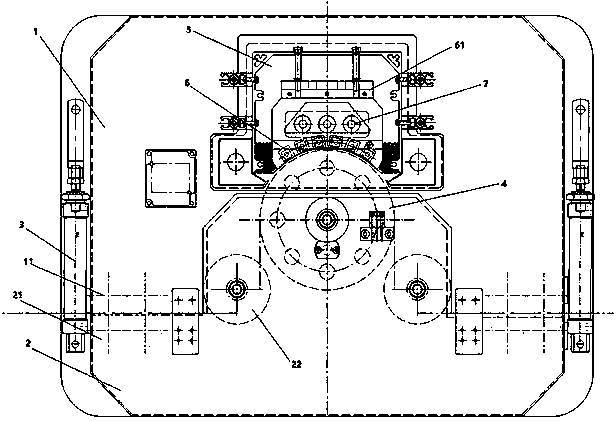

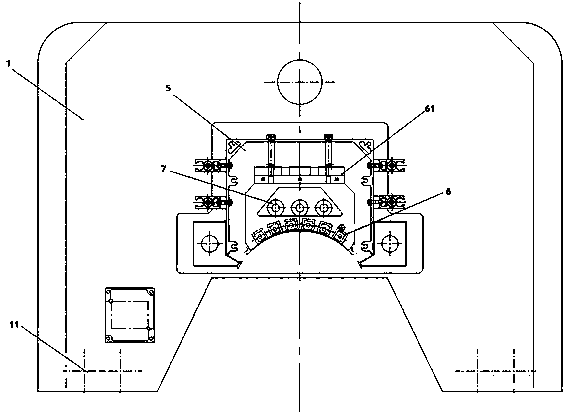

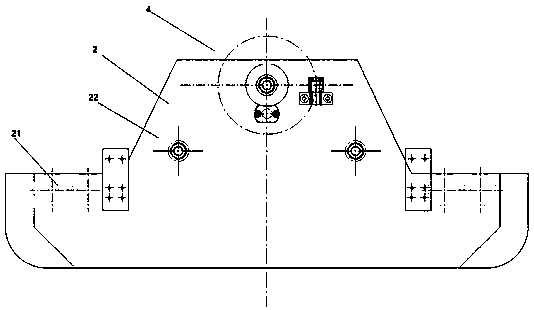

[0024] Such as Figure 1 to Figure 3 An inflatable fabric ceramic processing frame shown includes an upper frame 1 , a lower frame 2 , a lifting cylinder 3 , a corona roller 4 , an electrode cabin 5 , a ceramic electrode 6 and an inert gas channel 7 .

[0025] The upper frame 1 has a cylindrical structure, and the bottom end of the upper frame 1 is provided with a through groove for accommodating the corona roller 4 along the extension direction; mouth.

[0026] The lower frame 2 has a cylindrical structure, and the top end of the lower frame 2 is provided with a boss that matches the upper channel of the upper frame 1 along the extension direction; on the boss.

[0027] The bottom end of the lifting cylinder 3 is installed on the side of the lower frame, and the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com