Fabricated slotting tube pipe for soft soil foundation treatment

A soft soil foundation and assembly technology, applied in the engineering field, can solve problems such as unsatisfactory control of foundation horizontal deformation, achieve the effects of facilitating standardized production, broad application prospects, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

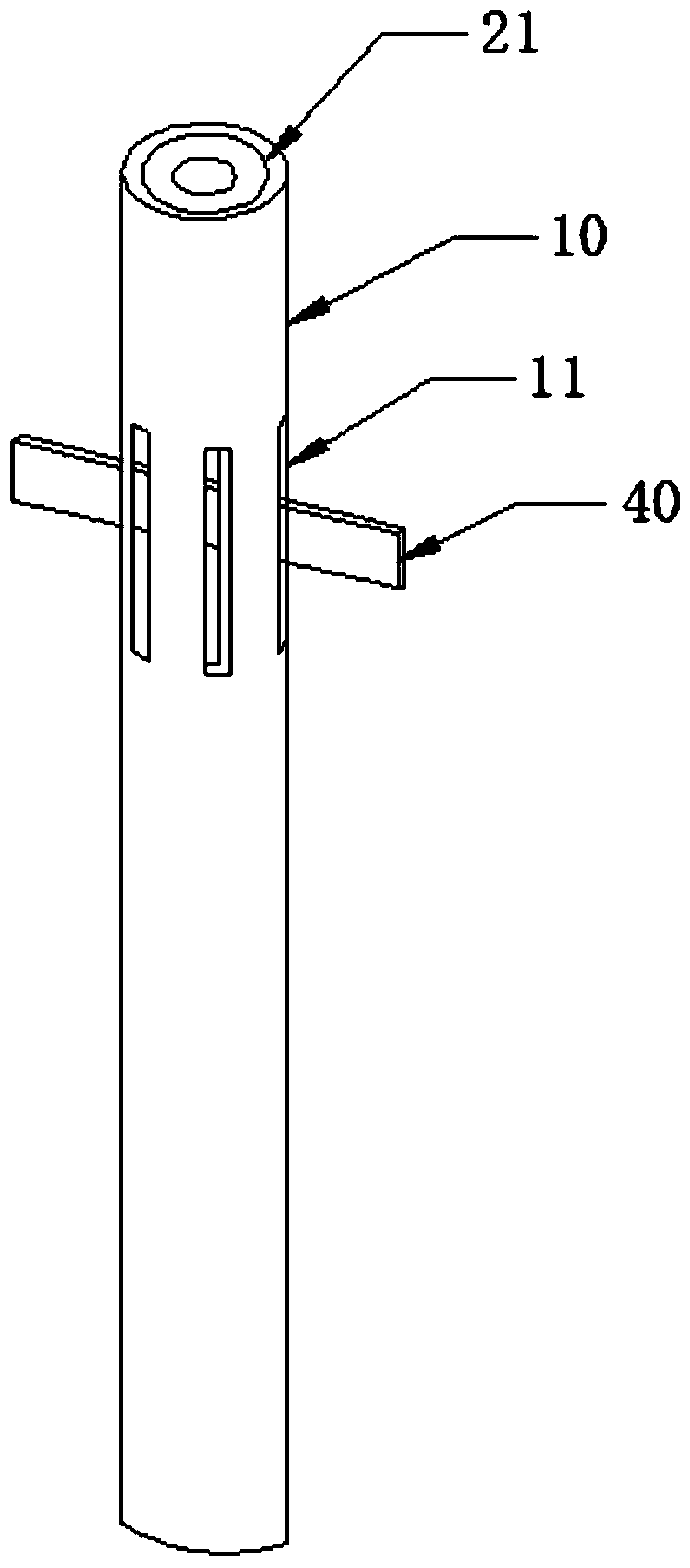

[0035] like Figure 1-3 As shown, the present invention provides an assembled slotted pipe pile for soft soil foundation treatment, including a pipe pile body 10 and a flank mechanism assembled in the pipe pile body 10, and further preferably, the pipe pile The body 10 may be a high-strength prestressed concrete pipe pile, and the pipe pile body 10 has a diameter of 300-600mm and a wall thickness of 70-130mm.

[0036] Further, the pipe wall at the upper part of the pipe pile body 10 is provided with through grooves 11; specifically, as shown in the figure, there are multiple groups of symmetrical through grooves 11 provided at the pipe wall at the upper part of the pipe pile body 10, preferably, the The length of the through groove 11 is 300-500 mm, and the width is 45-65 mm, and the position of the through groove 11 is at least 1.0 m below the pipe pile body 10 from the top.

[0037] Further preferably, the depth of the through grooves 11 runs through the wall thickness of t...

Embodiment 2

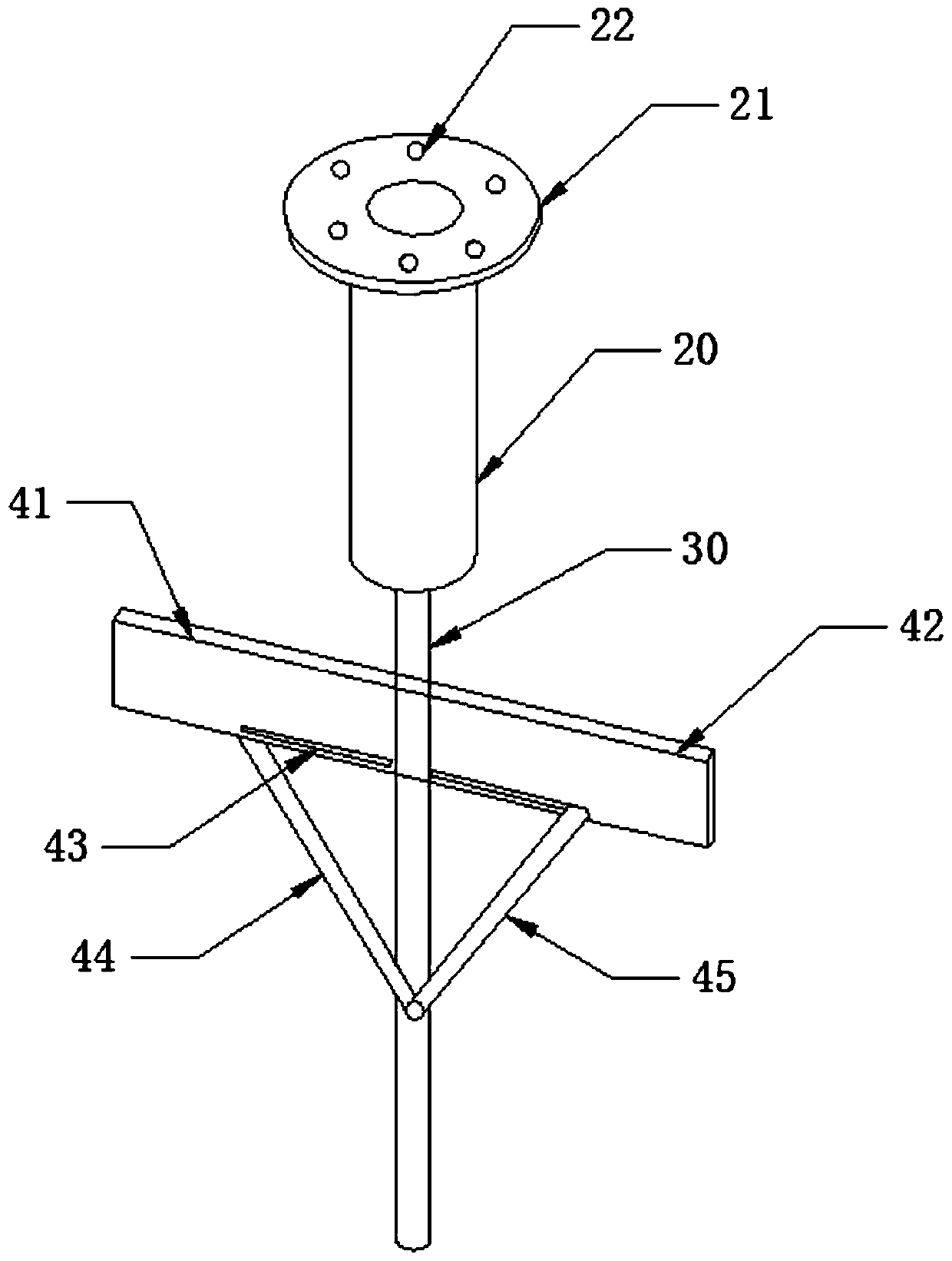

[0046] Such as Figure 4 As shown, the present invention provides an assembled slotted pipe pile for soft soil foundation treatment, including a pipe pile body 10 and a flank mechanism assembled in the pipe pile body 10, and further preferably, the pipe pile The body 10 may be a high-strength prestressed concrete pipe pile, and the pipe pile body 10 has a diameter of 300-600mm and a wall thickness of 70-130mm.

[0047] Further, the pipe wall at the upper part of the pipe pile body 10 is provided with through grooves 11; specifically, as shown in the figure, there are multiple groups of symmetrical through grooves 11 provided at the pipe wall at the upper part of the pipe pile body 10, preferably, the The length of the through groove 11 is 300-500 mm, and the width is 45-65 mm, and the position of the through groove 11 is at least 1.0 m below the pipe pile body 10 from the top.

[0048] Further preferably, the depth of the through grooves 11 runs through the wall thickness of ...

Embodiment 3

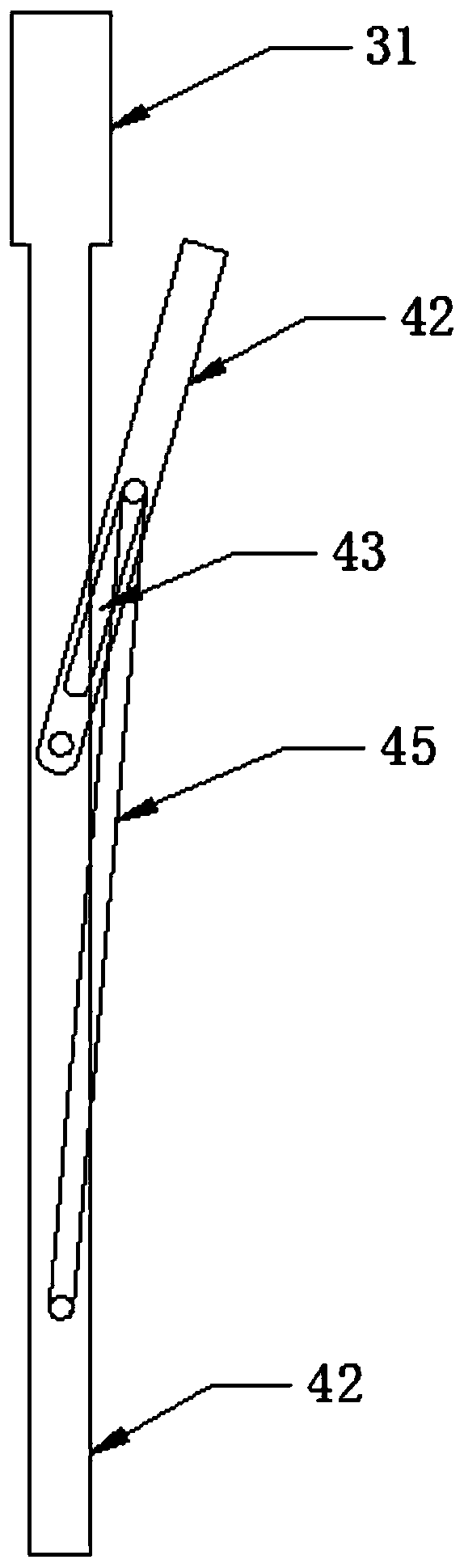

[0058] Such as Figure 5 As mentioned above, the present invention provides an assembled slotted pipe pile for soft soil foundation treatment, which includes a pipe pile body 10 and a flank mechanism assembled in the pipe pile body 10, and further preferably, the pipe pile The body 10 may be a high-strength prestressed concrete pipe pile, and the pipe pile body 10 has a diameter of 300-600mm and a wall thickness of 70-130mm.

[0059] Further, the pipe wall at the upper part of the pipe pile body 10 is provided with through grooves 11; specifically, as shown in the figure, there are multiple groups of symmetrical through grooves 11 provided at the pipe wall at the upper part of the pipe pile body 10, preferably, the The length of the through groove 11 is 300-500 mm, and the width is 45-65 mm, and the position of the through groove 11 is at least 1.0 m below the pipe pile body 10 from the top.

[0060] Further preferably, the depth of the through grooves 11 runs through the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com