Structure for reinforcing bearing wall of immature soil house and construction method

A load-bearing wall and wall technology, applied in building construction, building maintenance, construction, etc., can solve the problems of low land utilization, poor disaster resistance, low earthquake resistance, etc., to reduce construction costs, reduce construction periods, and improve Effects on Compressive Capacity and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

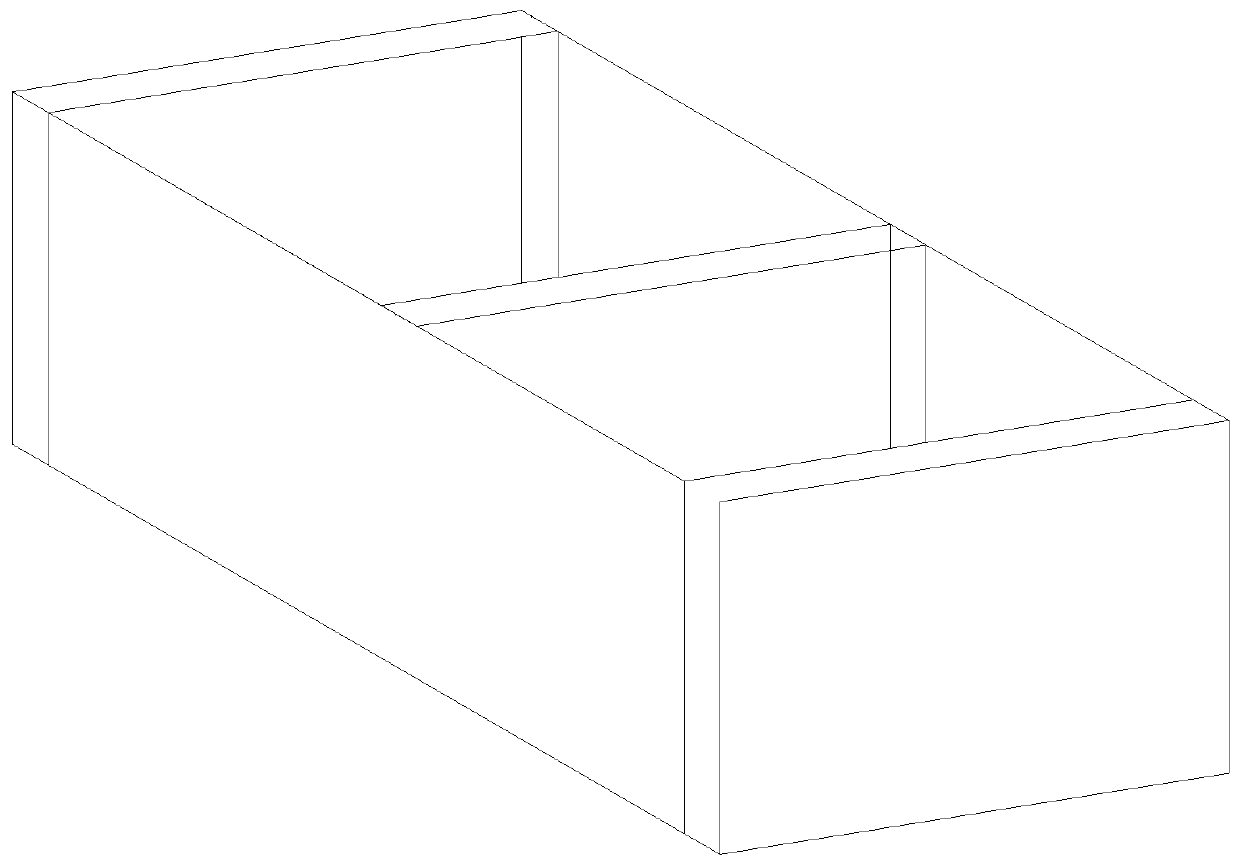

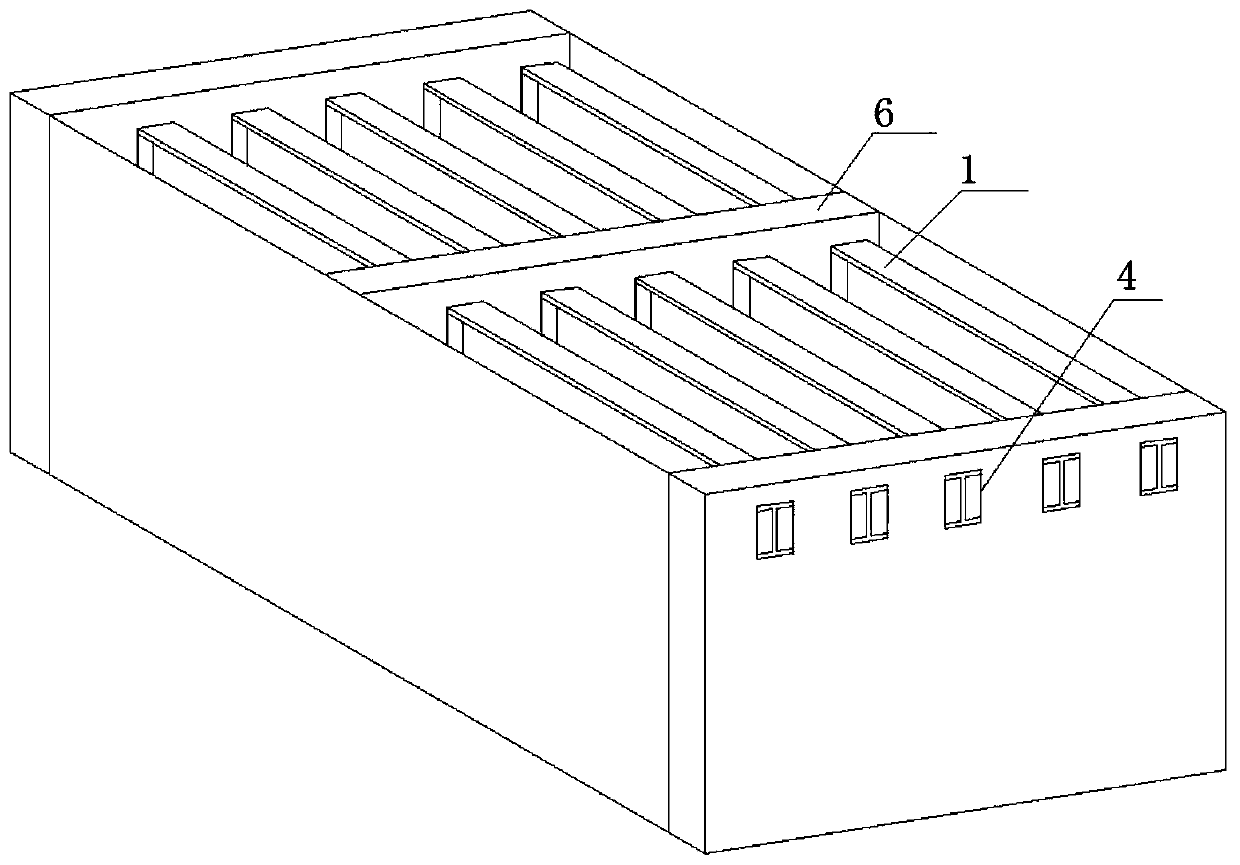

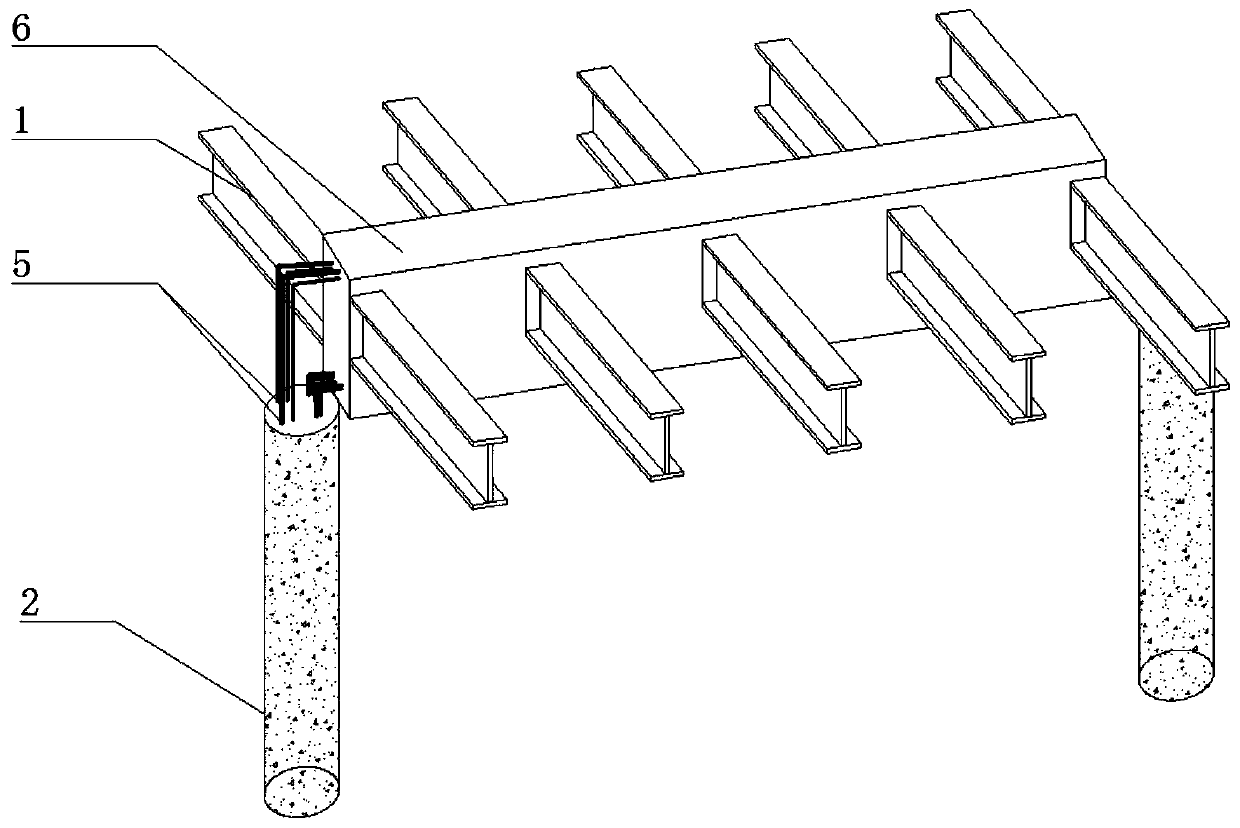

[0034] Embodiment 1, see Figure 1 to Figure 9, the present invention adopts the following technical scheme: a structure for reinforcing the load-bearing wall of a raw earth house, including an I-shaped support member 1, a support column 2, a support column accommodation hole 3, an installation hole 4, a support column steel bar 5, an underpinning Beam 6, underpinning beam steel bar 7, stirrup 8; it is characterized in that: installation holes 4 are drilled at an interval of 600mm between the proposed lintels, the height and width of the installation holes 4 are 15mm and 120mm respectively, and the I-shaped is set in the installation holes 4 In the supporting part 1, the support column reinforcement 5 and the underpinning beam reinforcement 7 are arranged on the upper and lower sides of the installation hole 4, and the stirrups 8 are arranged between the adjacent installation holes 4. Both sides of the load-bearing wall are drilled with support column accommodation holes 3 fro...

Embodiment 2

[0035] Example 2, see figure 2 , Figure 5 , a load-bearing wall reinforcement structure for raw earth houses, wherein: the distance between the installation holes 4 is about 600mm, and the bottoms of the installation holes 4 are on the same horizontal plane to ensure uniform and stable force. All the other are with embodiment 1.

Embodiment 3

[0036] Example 3, see figure 2 , Figure 5 , a load-bearing wall reinforcement structure of a raw earth house, wherein: the height×width of the installation hole 4=15mm×120mm. The size of the I-shaped support member 1 is consistent with the size of the mounting hole 4, and the bottom and top of the I-shaped support member 1 are tightly set with the wall body of the mounting hole 4, which can ensure the stability of the overall structure. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com