Transformer iron core grounding current online monitoring device

A transformer core and grounding current technology, applied in the direction of measuring devices, measuring current/voltage, instruments, etc., can solve problems such as single function, large amount of construction, risk of transformer operation, etc., achieve reliable data collection and transmission, and avoid waste of manpower and material resources , the effect of reducing operational risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

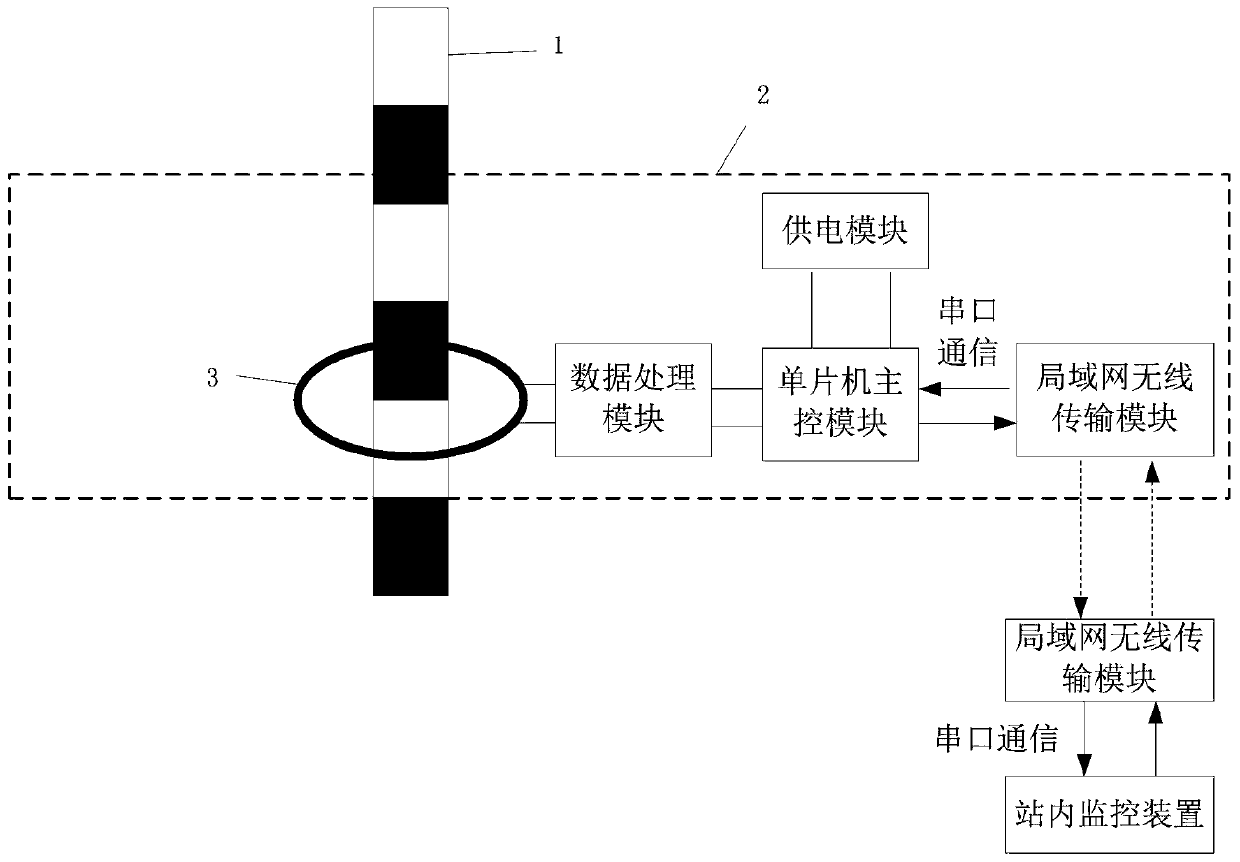

[0030] Such as figure 1 and figure 2 As shown, a transformer core grounding current online monitoring device includes a core grounding piece arranged on the main body of the transformer, a grounding current acquisition module set on the transformer core grounding piece and an in-station summary monitoring device;

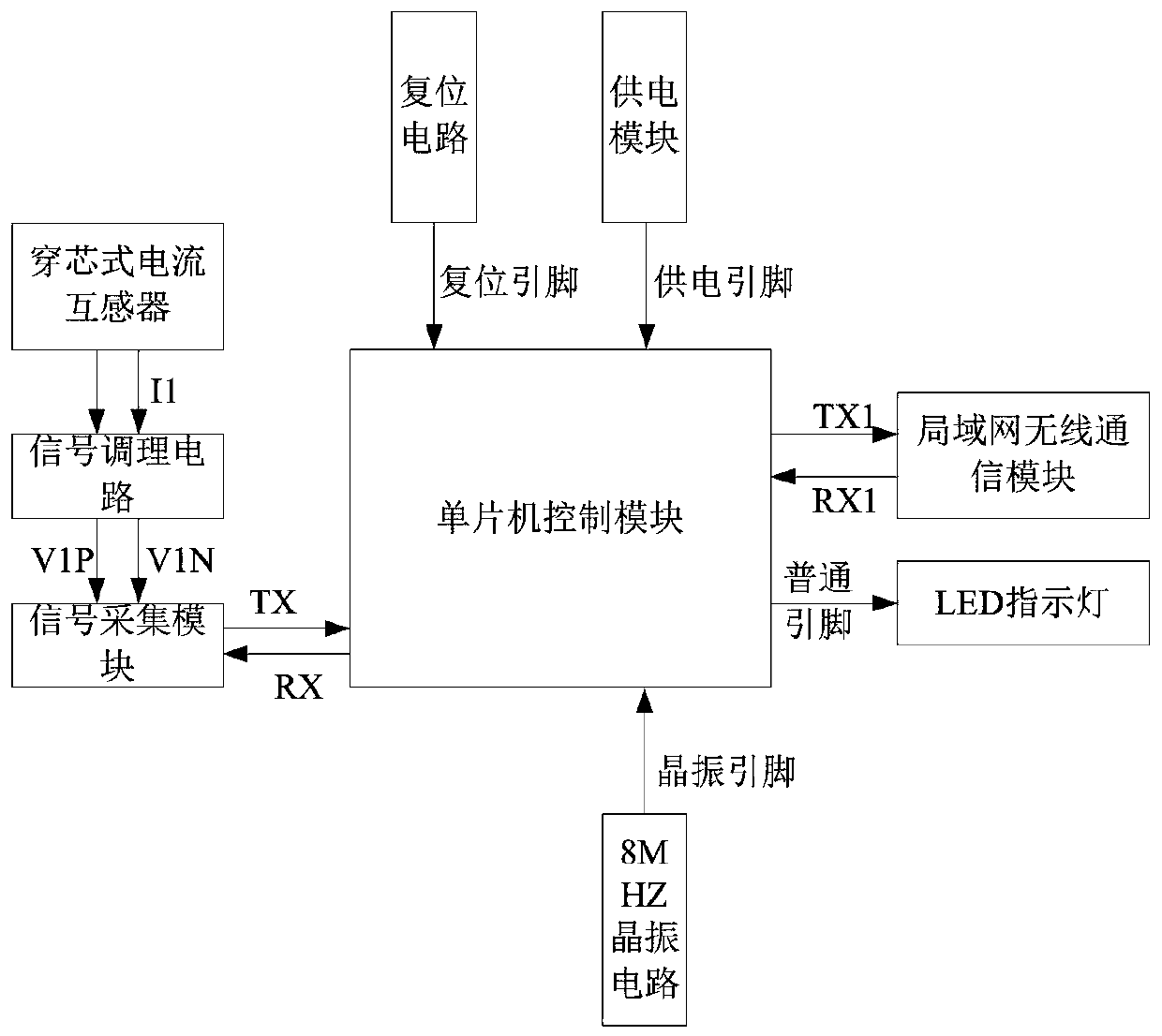

[0031] Ground current acquisition module, including transformer core ground current sensor, data processing module, single-chip microcomputer control module, LAN wireless transmission module and power supply module;

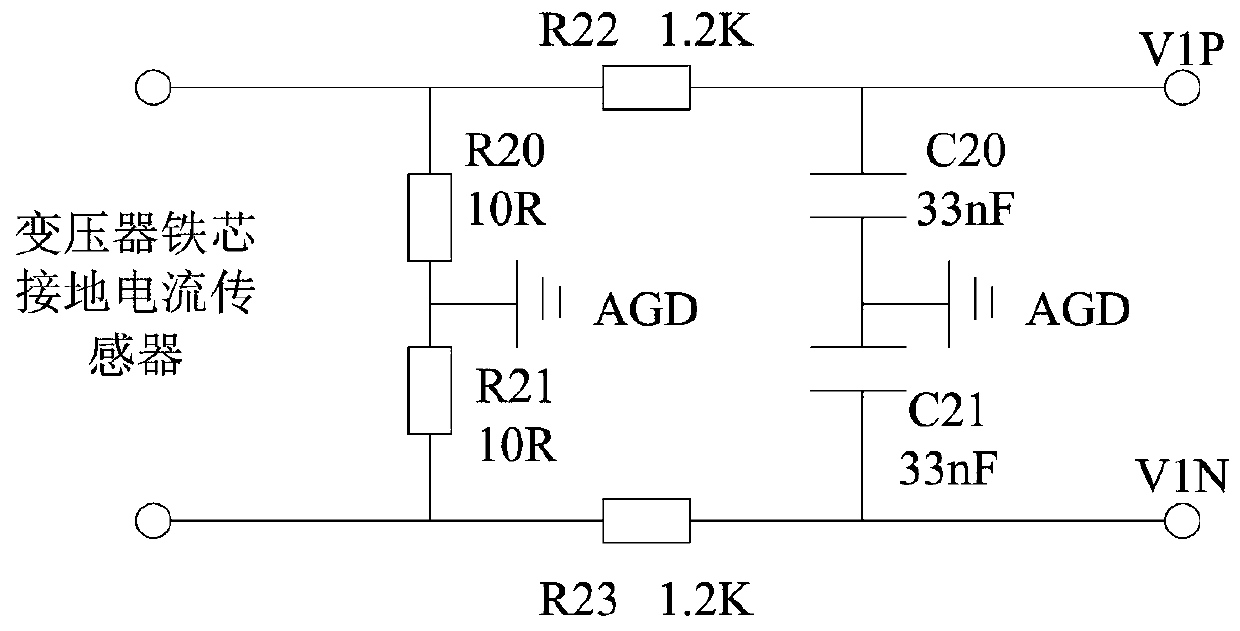

[0032] The transformer core grounding current sensor is set on the core grounding part of the transformer, and is used to obtain the power frequency AC small current signal of the core grounding part, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com