Modified furan resin production equipment and modified furan resin production method

A furan resin and production equipment technology, applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems of inconsistent fluidity, inability to achieve quantitative feeding of resin raw materials, etc., and achieve accurate raw material ratio and design. Ingenious, evenly mixed effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

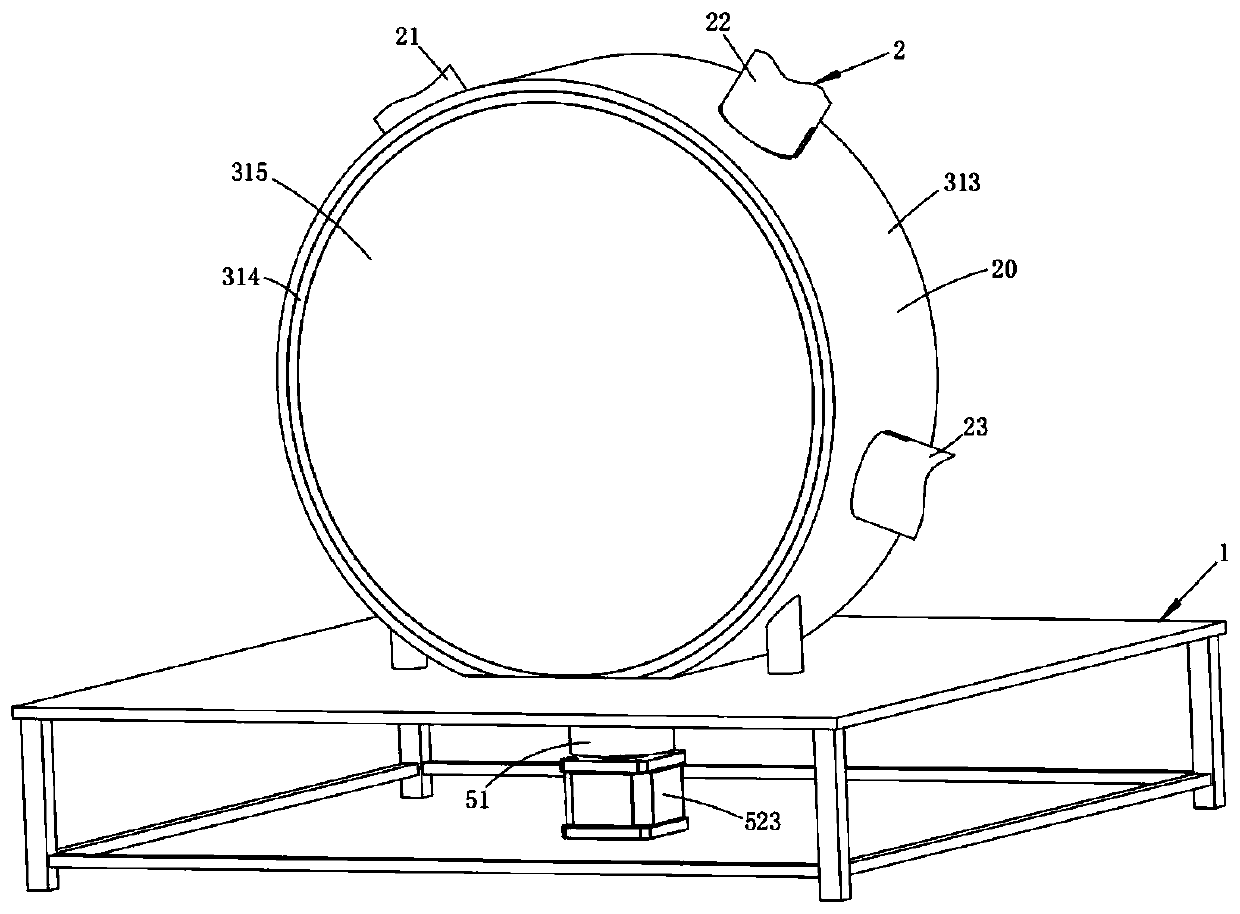

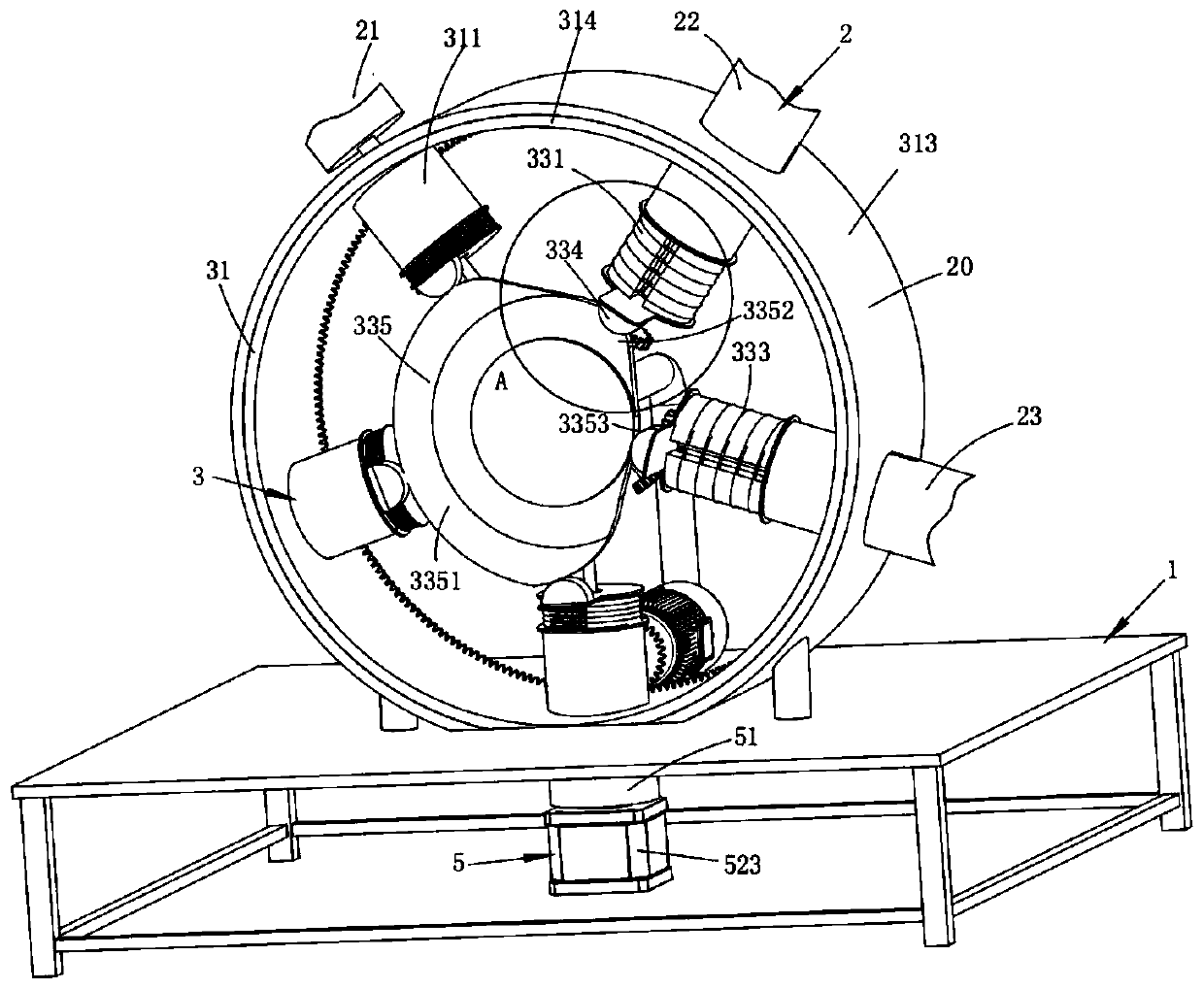

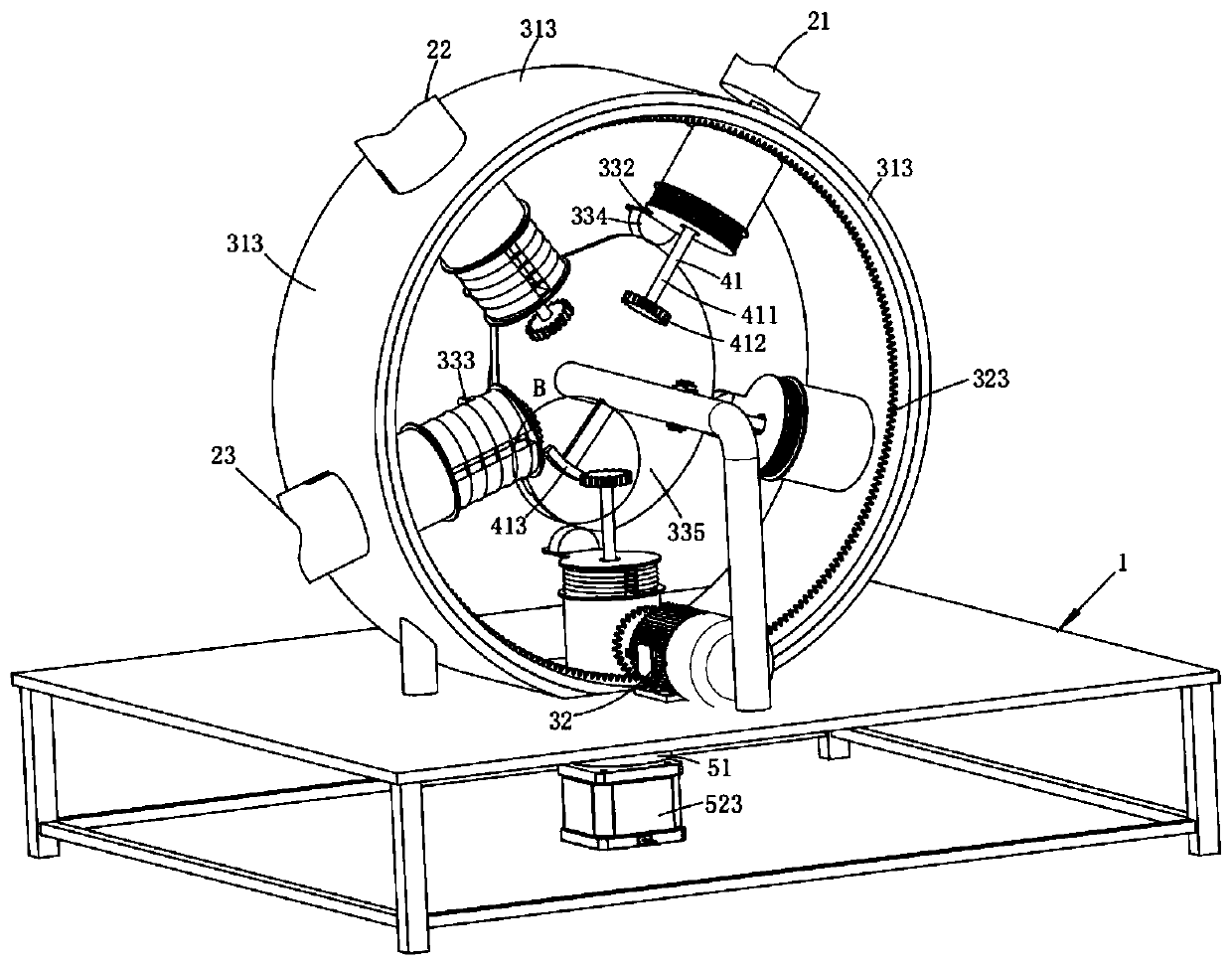

[0050] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of modified furan resin production equipment, comprises workbench 1, also comprises:

[0051] The feeding device 2, the feeding device 2 includes an anti-dumping component 20 and a first feeding port 21, a second feeding port 22 and a third feeding port 23 arranged around the anti-dumping component 20 in turn;

[0052] The material receiving device 3, the material receiving device 3 includes a material receiving assembly 31, a power assembly 32 and a limit assembly 33, and the material receiving assembly 31 is arranged inside the anti-dumping assembly 20, which includes a particle area 311 and is arranged on In the powder area 312 in the middle of the particle area 311, the power assembly 32 drives the material receiving assembly 31 to rotate and pass through the first feed port 21, the second feed port 22 and the third feed port 23 in sequence , the limiting component 33 is arranged in one-t...

Embodiment 2

[0077] Such as figure 2 and Figure 13 Shown, the invention provides a kind of production method of modified furan resin.

[0078] A modified furan resin production equipment and preparation method thereof, comprising the following steps:

[0079] Step 1, the first feeding process, the material receiving component 31 rotates to face the first feeding port 21, and the first feeding port 21 fills the powdery raw material A into the powder area 312 Inside;

[0080] Step 2, the second feeding process, after step 1, the material receiving assembly 31 rotates to face the second feeding port 22, the stop block 331 moves down, and the second feeding port 22. Fill the granular raw material B into the granular area 311;

[0081] It should be noted that the downward movement of the limiting block 331 is the result of the contact between the contact block 334 and the second contact portion 2252 .

[0082] Step 3, the third feeding process, after step 2, the material receiving assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com