Electrode wire assembly and electrostatic purification device applying electrode wire assembly

A purification device and pole wire technology, applied in the direction of electrostatic separation, external electrostatic separator, electrode structure, etc., can solve the problems of complicated pole wire fixed installation, increased assembly difficulty, ionization field strength, etc., to reduce installation steps Complexity, increase the charge capacity, and ensure the effect of adsorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

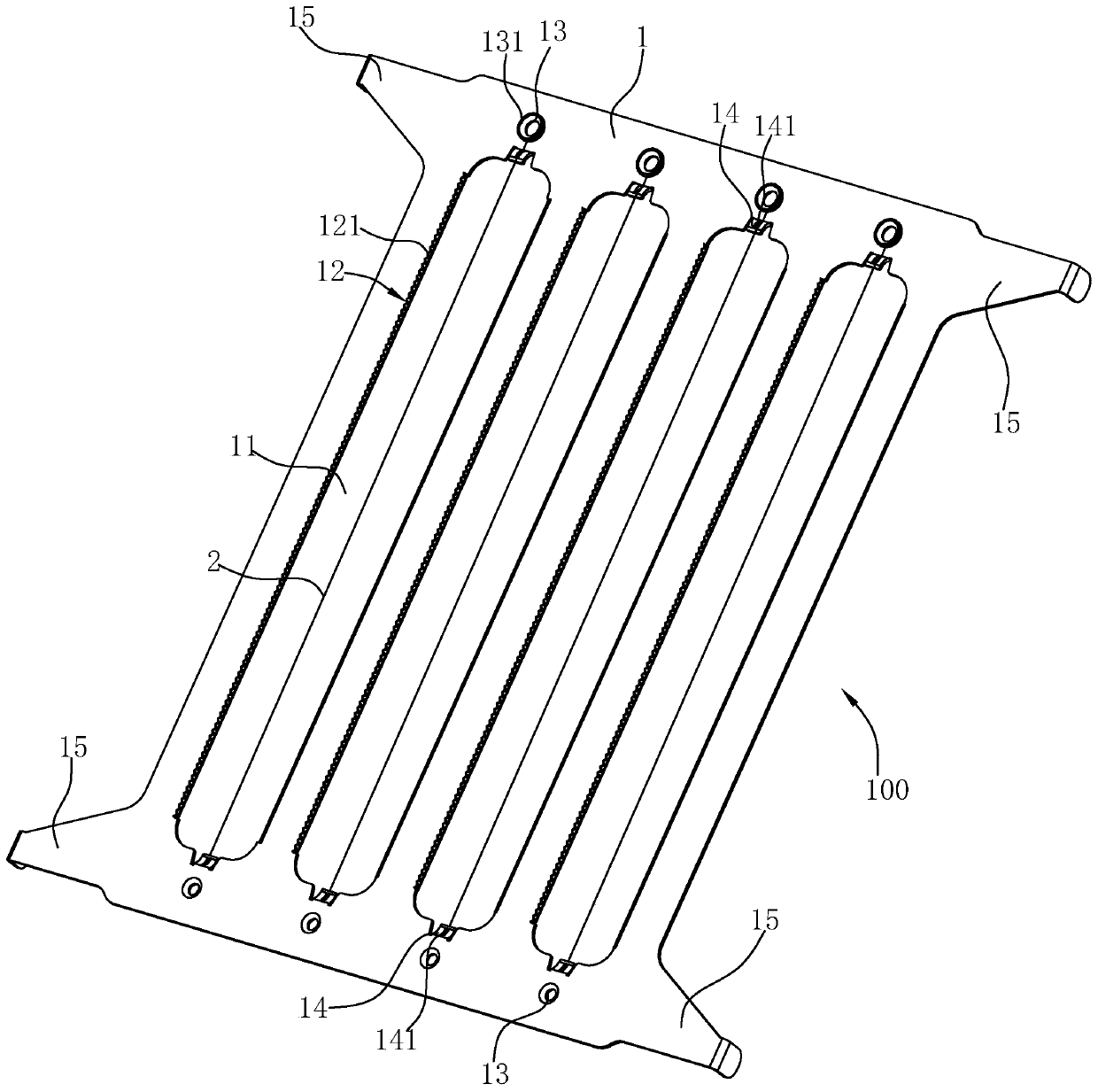

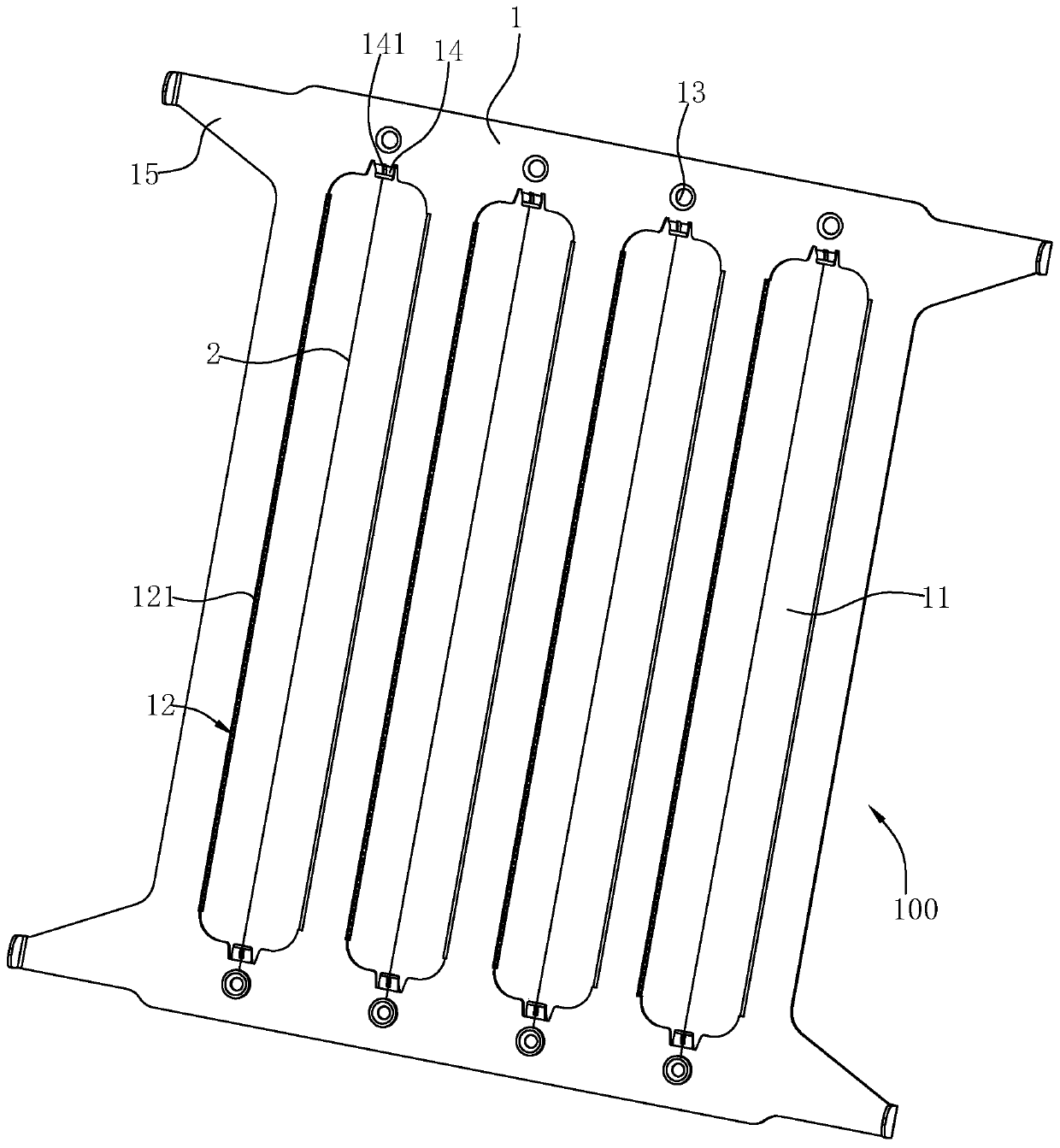

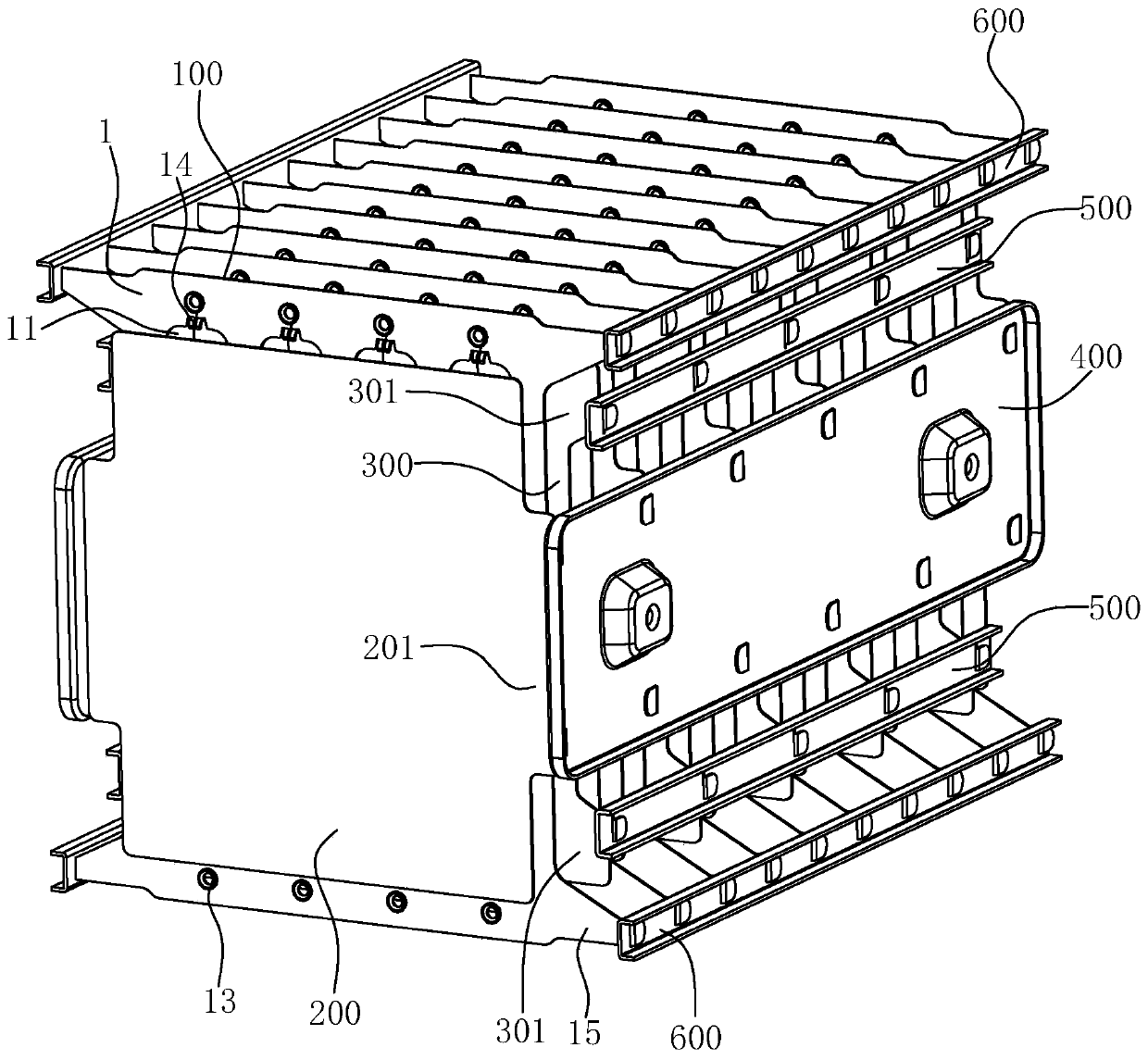

[0027] Such as figure 1 with figure 2 As shown, the pole wire assembly 100 in this embodiment includes a fixing plate 1 and a pole wire 2 connected to the fixing plate 1 .

[0028] The fixing plate 1 adopts a metal plate, and at least one strip-shaped hole 11 is arranged on the fixing plate 1, and the number of the strip-shaped holes 11 is more specifically set according to the pole wire 2 required. The fixed plate 1 in this embodiment is provided with at least two strip-shaped holes 11 in parallel, and each strip-shaped hole 11 is a rectangular hole. On the basis of ensuring the strength of the fixed plate 1, as many strip-shaped holes 11 are provided as possible.

[0029] The pole wire 2 extends along the length direction of the strip hole 11 , and then straddles the strip hole 11 . The two ends of each strip-shaped hole 11 on the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com