Ultrasonic cleaning method and cleaning device for flat enameled wire

A technology for enamelled flat wires and cleaning devices, which is applied to liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of reduced electrical performance of enamelled flat wires, high cost of enamelled flat wires, and easy Accumulate dirt and other problems to achieve the effect of eliminating the internal stress of the paint layer, improving electrical performance and reducing staffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

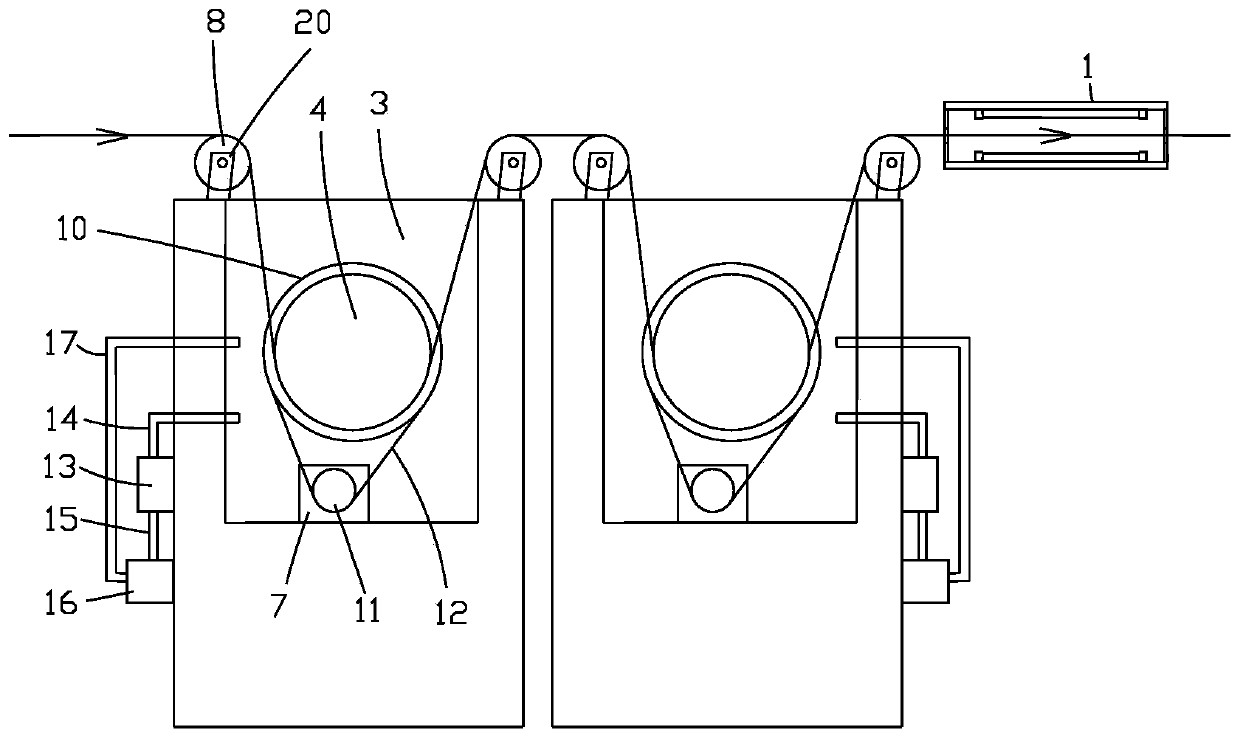

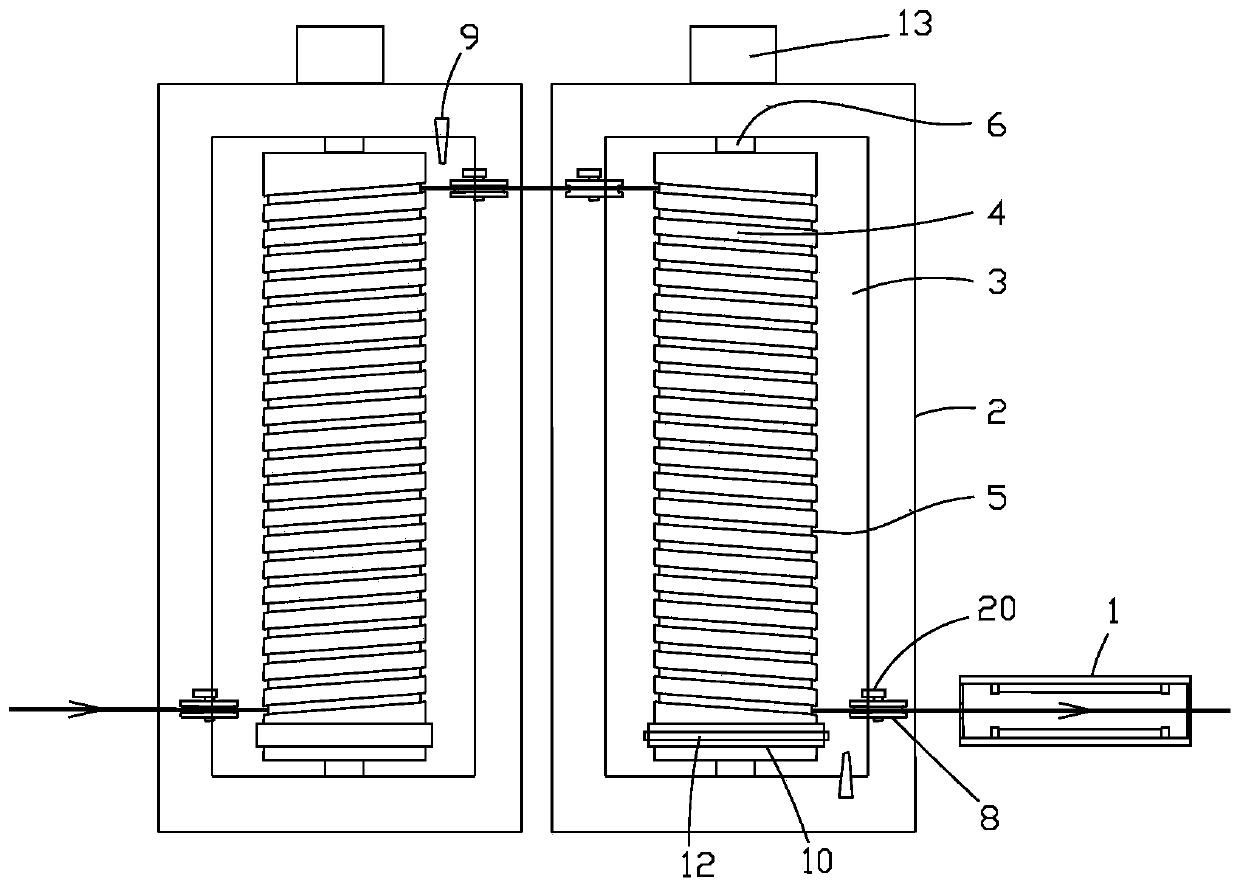

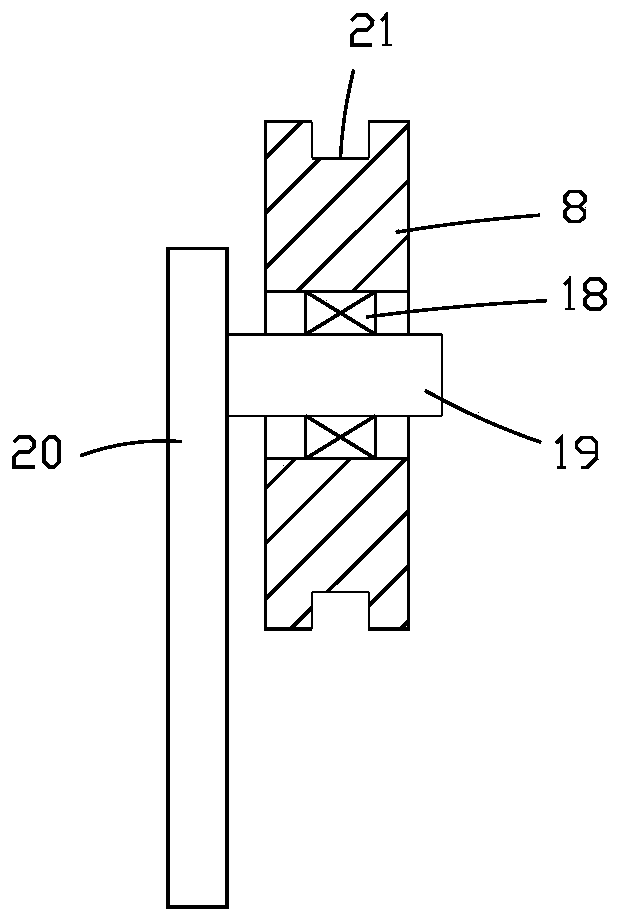

[0032] Example 1. A cleaning device for enamelled flat wire, such as figure 1 As shown, it includes a heater 1 and two ultrasonic cleaning machines 2, the ultrasonic cleaning machine 2 is provided with a cleaning tank 3, the cleaning tank 3 is provided with a drum 4 and a motor 7, and the outer peripheral surface of the drum 4 is provided with a spiral groove 5, The cross-section of the spiral groove 5 is the same as that of the enamelled flat wire. Both ends of the drum 4 are connected to the inner wall of the cleaning tank 3 through the first bearing 6, and the drum 4 is connected to the motor 7 through a transmission mechanism; Two guide wheels 8, two guide wheels 8 are positioned at the both sides of cylinder 4 respectively, and two guide wheels 8 are adjacent to the two ends of cylinder 4 respectively; The top of cleaning tank 3 is provided with air gun 9.

[0033] The transmission mechanism includes a driven wheel 10 arranged at one end of the drum 4 and a driving wheel...

Embodiment 2

[0050] Example 2. A cleaning device for an enamelled flat wire, the structure of which is the same as that of the cleaning device in Embodiment 1.

[0051] A cleaning method for enamelled flat wire: it is basically the same as the cleaning method in Example 1, the difference lies in the following points: (1), the first cleaning solution includes 1000 parts of water and a diameter of 0.1 mm in parts by weight 10 parts of microplastics, 3 parts of dispersant and 2 parts of chelating agent;

[0052] (2), the second cleaning solution comprises 1000 parts of deionized water and 20 parts of absolute alcohol;

[0053] (3), the ultrasonic frequency of the ultrasonic cleaning machine 2 in step a is 20kHz, and the cleaning time is 10s; the length of the cleaning time can be realized by adjusting the number of winding turns of the enamelled flat wire on the corresponding spiral groove 5;

[0054] (4), the ultrasonic frequency of the ultrasonic cleaning machine 2 in step c is 40kHz, and...

Embodiment 3

[0056] Example 3. A cleaning device for an enamelled flat wire has the same structure as that of the cleaning device in Example 1.

[0057] A cleaning method for enamelled flat wire: basically the same as the cleaning method in Example 1, the difference lies in the following points: (1), the first cleaning solution includes 1000 parts of water and a diameter of 0.2 mm in parts by weight 5 parts of microplastics, 5 parts of dispersant and 1 part of chelating agent;

[0058] (2), the second cleaning solution comprises 1000 parts of deionized water and 50 parts of absolute alcohol;

[0059] (3), the ultrasonic frequency of the ultrasonic cleaning machine 2 in step a is 25kHz, and the cleaning time is 20s;

[0060] (4), the ultrasonic frequency 35kHz of the ultrasonic cleaning machine 2 in the step c, cleaning time 5s,

[0061] (5), the temperature in the heater 1 in step 4e is 300° C., and the residence time of product D in the heater 1 is 10 s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com