Assembly die base and production technology thereof

A production process and assembly technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of gaps between A board and B board, mold cavity damage, impurity entry, etc., to avoid the level Offset, strong wear resistance, and life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

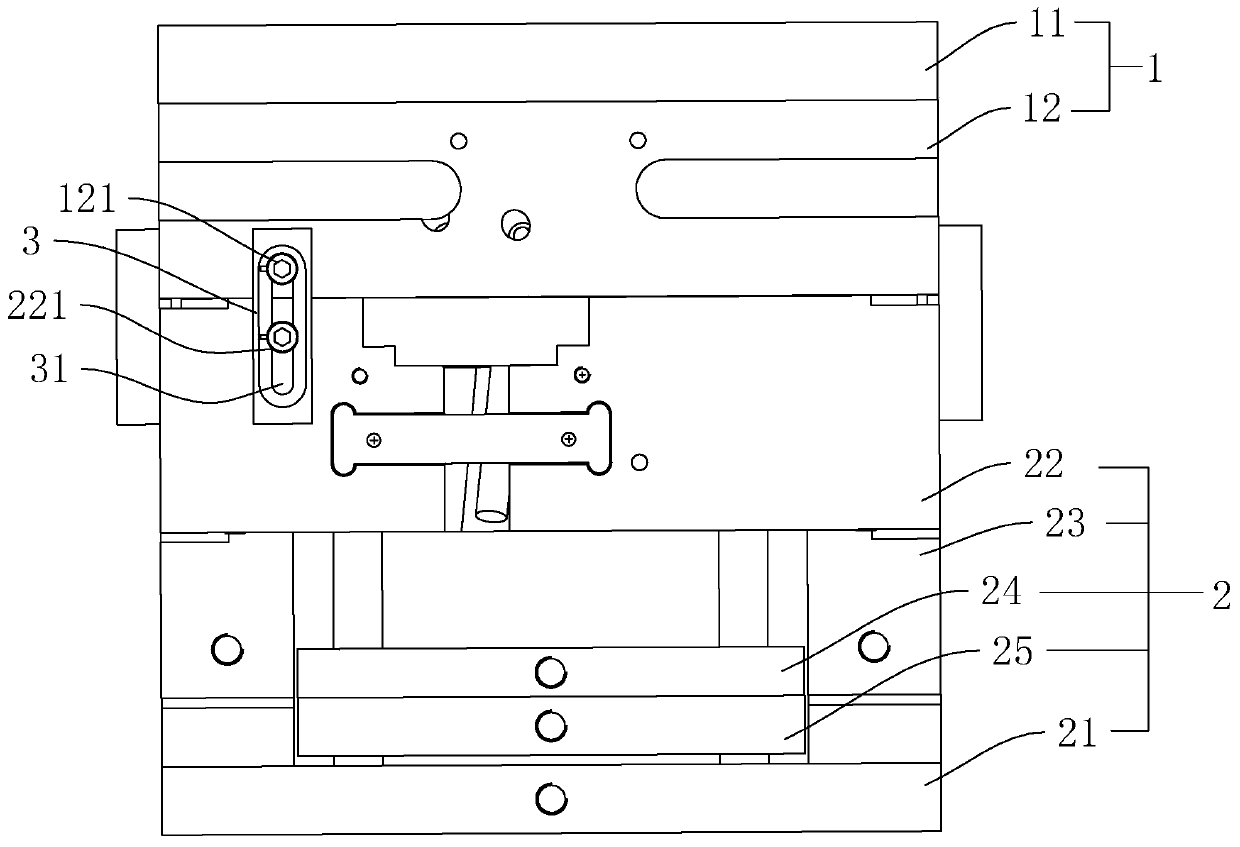

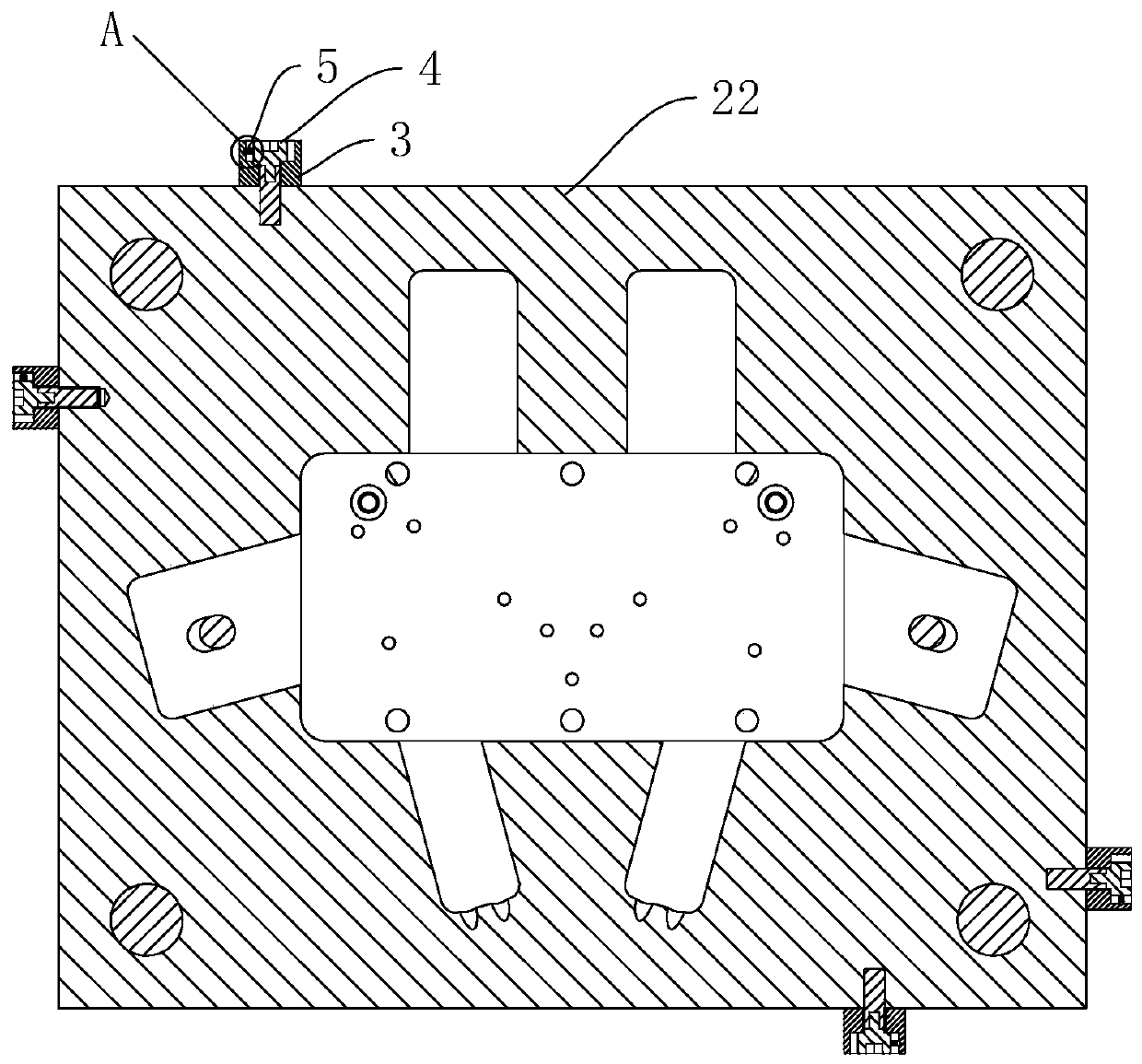

[0046] An assembled formwork such as figure 1Shown, comprise upper mold 1 and lower mold 2, upper mold 1 comprises panel 11 and the A board 12 that is installed on the lower surface of panel 11, lower mold 2 comprises bottom plate 21, B board 22, square iron 23, needle face plate 24 and Bottom needle plate 25, face needle plate 24 and bottom needle plate 25 are located in the area surrounded by base plate 21, square iron 23 and B plate 22.

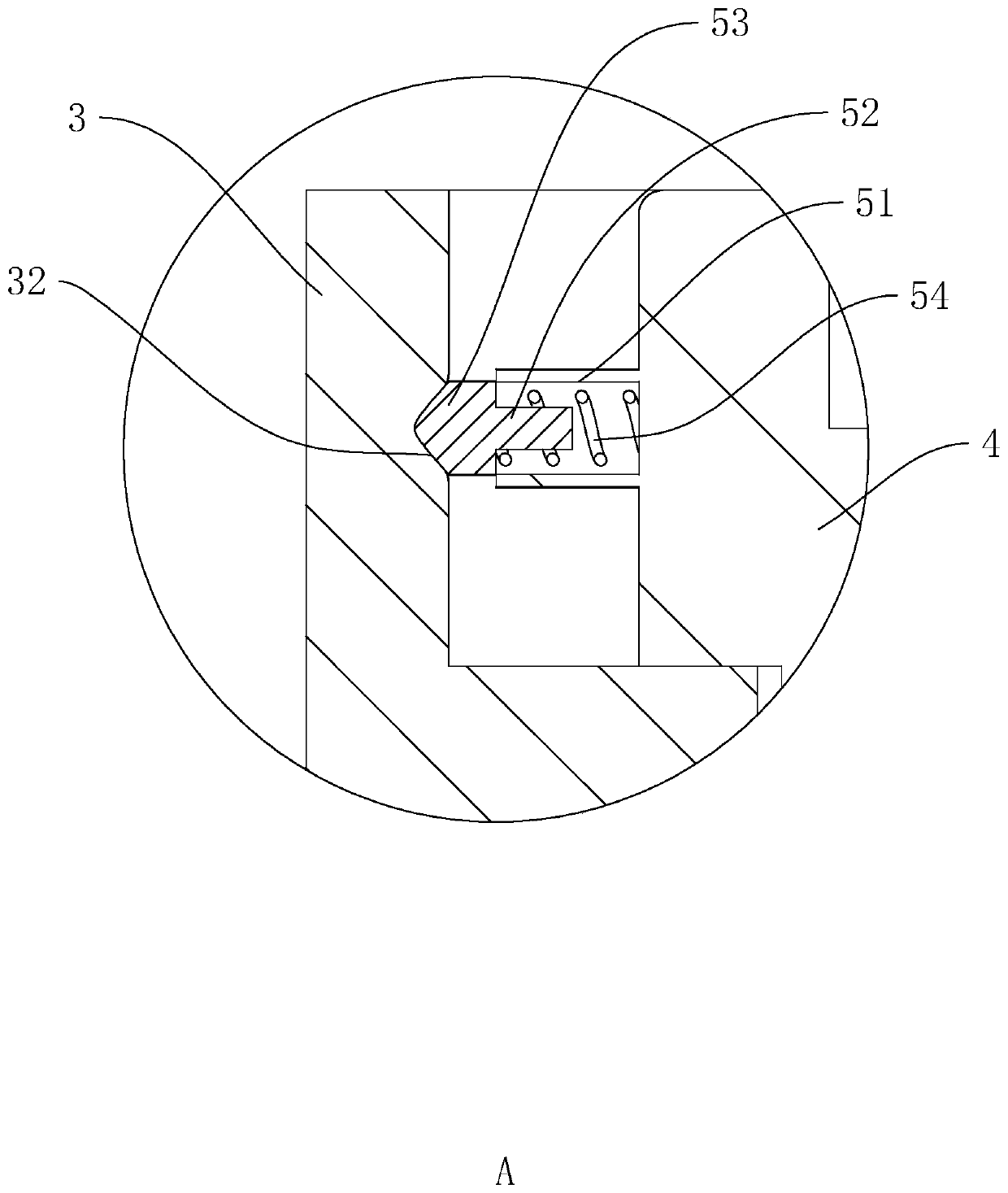

[0047] Such as figure 1 , 2 As shown, four lock modules 3 connecting the A board 12 and the B board 22 are arranged between the upper mold 1 and the lower mold 2. The four lock modules 3 are distributed on the four sides of the A board 12, and the lock modules 3 are fixed on the A board. On the outer wall of the plate 12. Wherein, each lock module 3 is provided with a chute 31 in the vertical direction, and the A plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com