Uniform ventilation system for compost reactor

A composting reactor and ventilation system technology, which is applied in the uniform ventilation system field of composting reactors, and can solve problems such as the lack of pipeline design basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

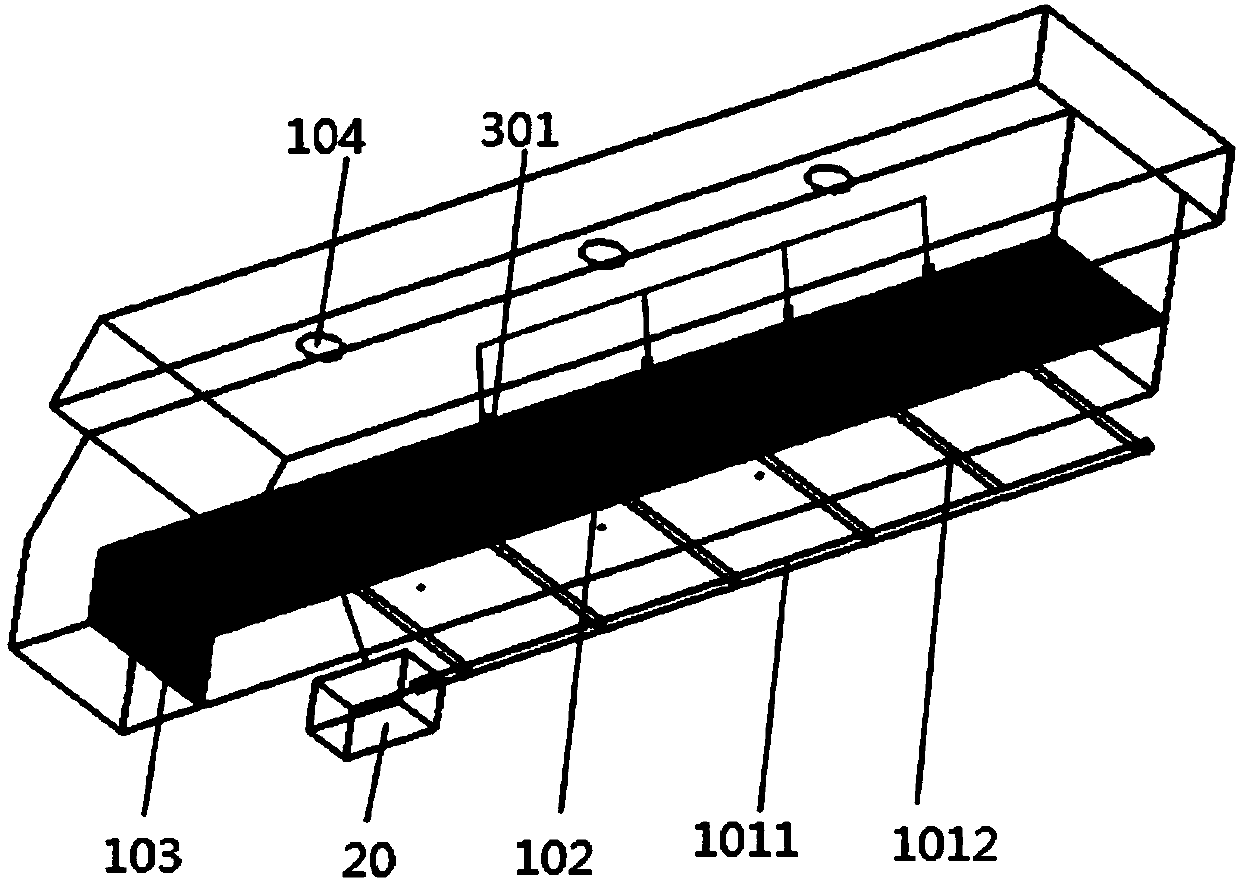

[0057] Further description will be given below through the embodiments shown in the accompanying drawings.

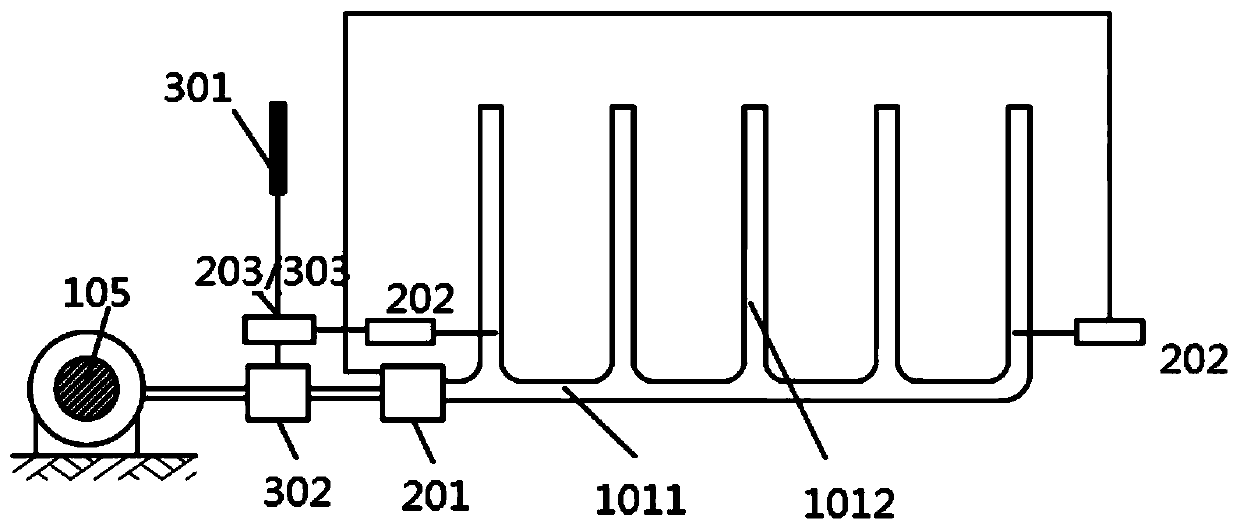

[0058] The ventilation system of this embodiment includes a ventilation control device, a temperature control device and a ventilation device. The ventilation device also includes ventilation ducts, chain plates, steel plates, air outlets and fans. The structure of each component in this embodiment is similar to that of the above-mentioned embodiment.

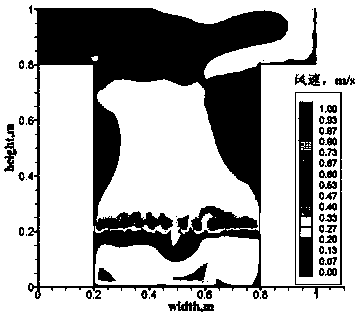

[0059] The chain plate and steel plate (with no small holes on the steel plate) under the pile body form a closed space with the bottom of the composting reactor, and the ventilation pipe is located in this closed space. The air outlet is located above the stack. After the ventilation system is started, the airflow enters the stack through the small holes on the chain plate, exchanges heat and gas with the stack, and then flows out through the air outlet above the stack.

[0060] The air duct includes a main pipe and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com