Net cage device for beater production of fiber cement pressure plate

A technology of fiber cement and pressure plate, which is applied in the direction of textiles and papermaking, paper machine, paper machine wet end, etc., can solve the problems of increased maintenance cost, inconvenient maintenance, and cumbersome operation process, so as to improve processing capacity and improve copying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

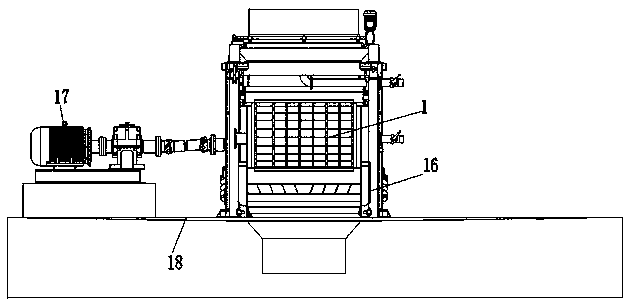

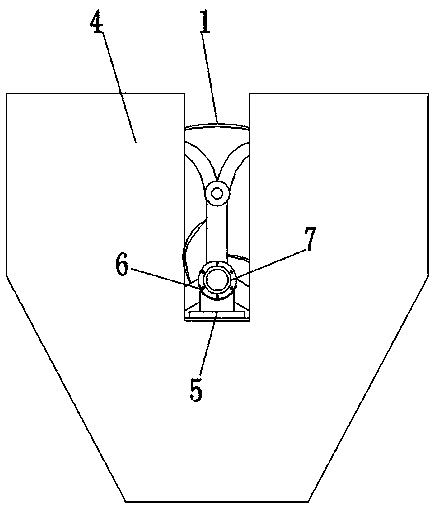

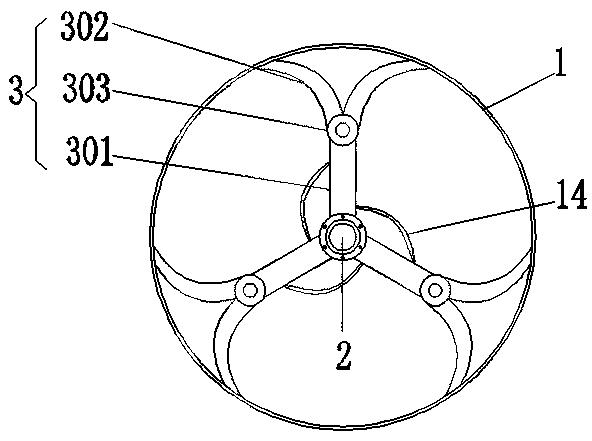

[0025] Please refer to Figure 1-Figure 4 , the present invention provides a net cage device for fiber cement pressure board production, comprising a net cylinder 1 and a support shaft 2 coaxially arranged inside the net cylinder 1, and a box body 4 is sleeved on the outside of the net cylinder 1, and the box body 4 Both ends are provided with a gap at the top, the bottom of the gap is connected with a bearing seat 5, the top of the bearing seat 5 is provided with a sub-arc-shaped supporting plate 6, the supporting plate is supported by a bearing body 7, and the outer cylindrical surface of the net cylinder 1 There is a mesh cloth that can be attached to the top of the wool cloth to carry out the copying operation. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com