Stretchable lead and preparation method thereof

A wire and substrate technology, applied in the field of stretchable wire and its preparation, can solve the problems of harsh preparation conditions, complicated preparation process, etc., and achieve the effect of solving the complex preparation process, difficulty in mass production, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the second aspect of the embodiment of the present invention, there is provided a method for preparing the stretchable wire according to the first aspect of the embodiment of the present invention, the method includes: using a semi-cured flexible material to prepare a substrate with grooves; making the semi-cured flexible material The cover plate is bonded to the base to seal the grooves on the base to form a sealed hollow pipe; the liquid metal is injected into the hollow pipe so that the liquid metal is distributed in the hollow in a flowing state In the pipe, a metal circuit layer is obtained; the hollow pipe with the metal circuit layer is solidified to obtain a stretchable wire.

[0032] In the embodiment of the present invention, a hollow pipe is made by using a base and a cover formed of a semi-cured flexible material, and the liquid metal is injected into the hollow pipe and then solidified to obtain a stretchable wire; thereby realizing rapid and large-scale ...

Embodiment 1

[0053] A stretchable wire includes: a substrate made of semi-cured PDMS, a cover plate made of semi-cured PDMS and a metal circuit layer formed of a gallium-based alloy. There are linear grooves on the substrate; the cover plate and the substrate are bonded and connected to seal the linear grooves to form a sealed hollow pipe; the gallium-based alloy is distributed in the hollow pipe in a flowing state to form a metal circuit layer for conducting through the circuit.

[0054] In the embodiment of the present invention, there is no limitation on the preparation method of the stretchable wire, as long as the stretchable wire can be obtained.

Embodiment 2

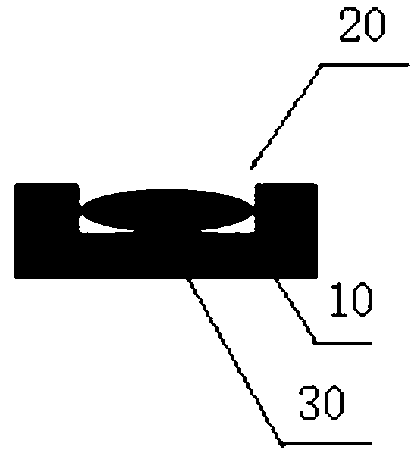

[0056] A stretchable wire includes: a substrate 10 made of semi-cured silicone rubber, a cover plate 20 made of semi-cured silicone rubber, and a metal circuit layer 30 formed of a liquid composite material of indium-based alloy and Ni nanoparticles. The substrate 10 is provided with linear grooves; the cover plate 20 and the substrate 10 are bonded and connected, and are used to encapsulate the linear grooves to form a sealed hollow pipe; the liquid composite material of indium-based alloy and Ni nanoparticles is distributed in a flowing state. A metal circuit layer 30 is formed in the hollow pipe for conducting the circuit.

[0057] The preparation method of the stretchable wire in the embodiment of the present invention is as follows:

[0058] Step 1: Use Teflon material as the template material to construct a template with linear grooves; spread the substrate made of semi-cured silicone rubber on the template and take it out after applying force to obtain a substrate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com