Method and system for reducing oxidation speed of electrode of flow battery

A liquid flow battery and electrode oxidation technology, which is applied in the direction of regenerative fuel cells, etc., can solve the problems of little protective electrode effect and no substantial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

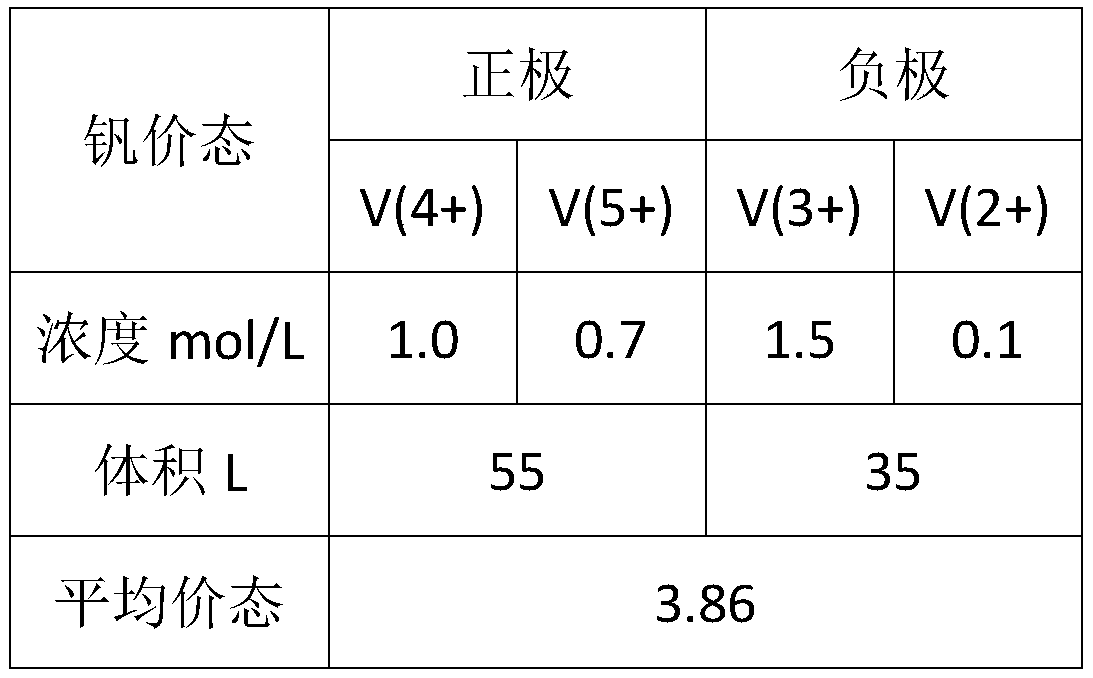

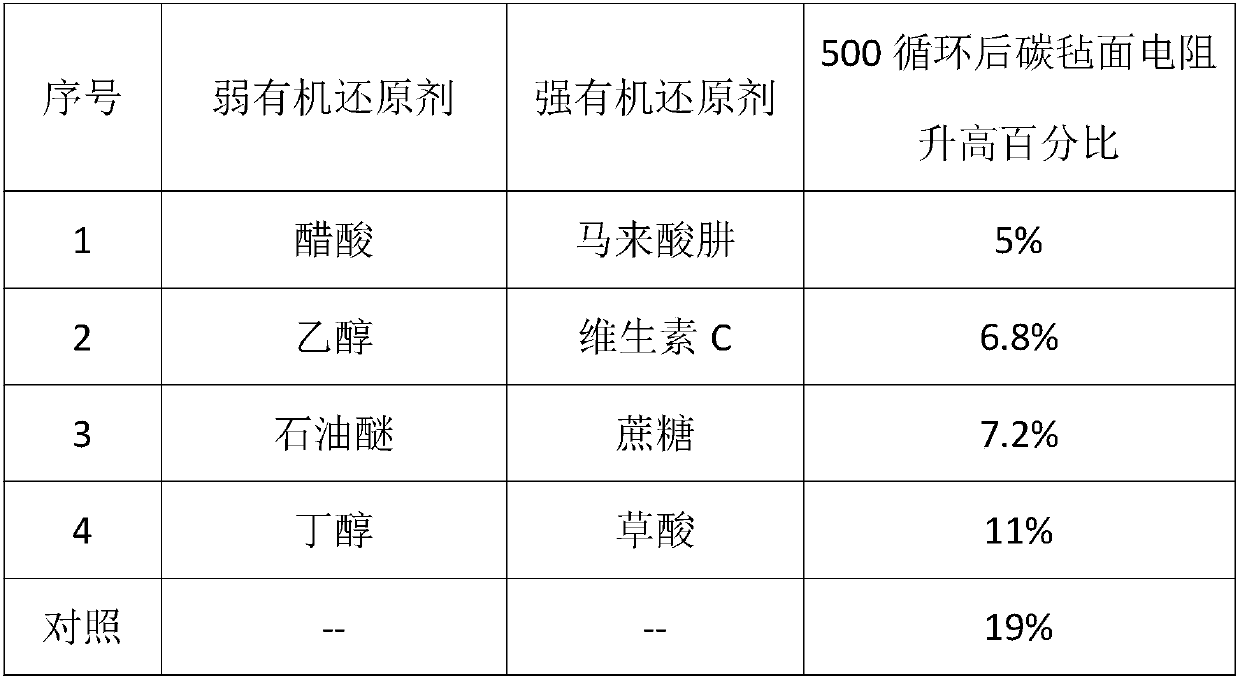

[0021] In this embodiment, a method for reducing the oxidation rate of the electrodes of the flow battery is to quickly determine the overall average valence state of the positive and negative electrolytes before the SOC of the positive electrolyte reaches 85%. When the overall average valence state is ≥3.6, specifically, when the SOC of the positive electrode electrolyte is greater than 85% at the end of charging, method 1 is used to reduce the oxidation speed of the positive carbon felt electrode—the method of automatically adding a reducing agent; when When the overall valence state is <3.6, specifically, when the SOC of the positive electrode electrolyte is greater than 80%, use method 2 to reduce the oxidation rate of the positive carbon felt electrode—introduce part of the negative electrode electrolyte to the positive electrode.

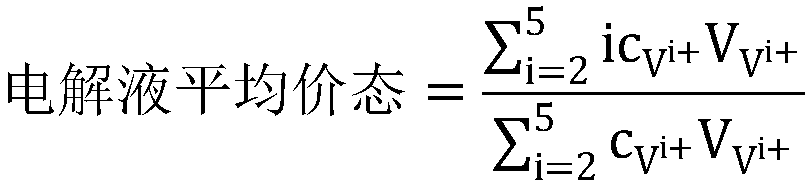

[0022] Among them, the calculation method of the overall average valence state of the electrolyte is as follows:

[0023] There are four vale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com