Patents

Literature

37results about How to "Slow oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing material containing amorphous iron oxide hydroxide and methods for regenerating the same

ActiveCN101767830AHigh sulfur capacityGood desulfurization effectIron oxides/hydroxidesIron oxideHydroxide

The invention relates to a method for preparing a material containing amorphous iron oxide hydroxide and two methods for regenerating the same after being used as desulfurizer. The content of the amorphous iron oxide hydroxide in the material prepared by the invention is as high as 65% to 100%, so the sulfur capacity of the material is high; and the desulfurizer in the prior art is non-regenerative or costly for regeneration, so that the desulfurizer in a large amount cannot but be dumped as waste liquid in landfills, while the amorphous iron oxide hydroxide in the material of the invention can be repeatedly regenerated and reused after the material is used as the desulfurizer, thereby solving the problems of the waste of effective resources in the original desulfurizer and the severe environmental pollution.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Luminous epoxy paint and preparation method thereof

ActiveCN102876199ALong glow timeImprove performanceLuminescent paintsEpoxy resin coatingsEpoxyCompound a

The invention discloses a luminous epoxy paint and a preparation method thereof. The paint is obtained by compounding a component A and a component B, wherein the component A comprises the following components by weight percent: 40-55% of epoxy resin, 40-55% of fluorescent powder, 2-8% of thickening agent, 0.1-0.6% of defoaming agent and 0.1-0.6% of levelling agent; the component B comprises the following components by weight percent: 40-55% of curing agent, 40-55% of fluorescent powder, 2-8% of thickening agent, 0.1-0.6% of defoaming agent and 0.1-0.6% of levelling agent; and the component A and the component B are compounded according to the part ratio of 1:1) to 2:1) The paint has the following beneficial effects: the paint has longer luminescence time, the fluorescent effect is enhanced and the fluorescent powder is not easy to pulverize; and in the use process, the fluorescent paint has good yellowing and weather resistances and long service life.

Owner:上海维度化工科技有限公司

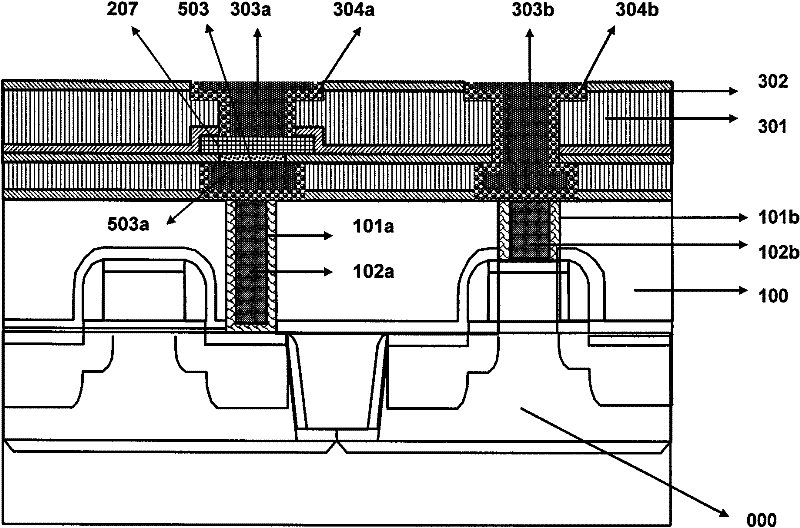

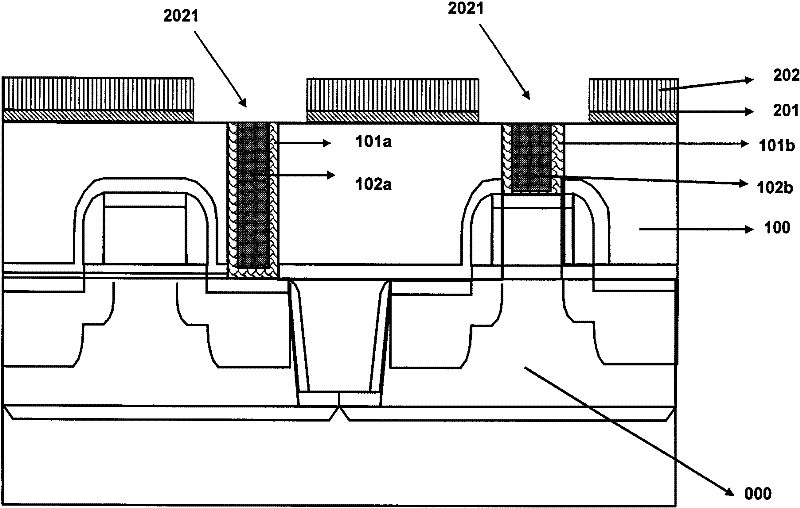

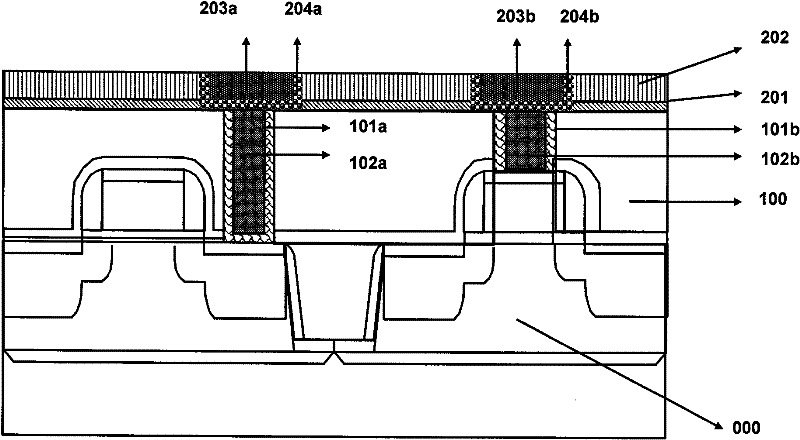

Method for integrating manganese-oxide-based resistive memory with copper interconnection rear end process

InactiveCN102237309AThe manufacturing process is perfectly compatibleImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingProcess integrationInterconnection

The invention belongs to the technical field of semiconductor memories and particularly relates to a method for integrating a manganese-oxide-based resistive memory with a copper interconnection rear end process. In the method for process integration, manganese metal in a cap layer on a copper lead wire is siliconized to form a MnSi compound layer and the MnSi compound layer is oxidized to form aMnSi(x)O(y) storage medium layer; and a manganese silica compound layer is used as a barrier layer of the copper lead wire at a copper interconnection rear end. The method has the advantages of compatibility with the copper interconnection rear end process with process nodes equal to or less than 45 nanometers; and the manganese-oxide-based resistive memory has low preparation cost, high reliability and low power consumption.

Owner:FUDAN UNIV

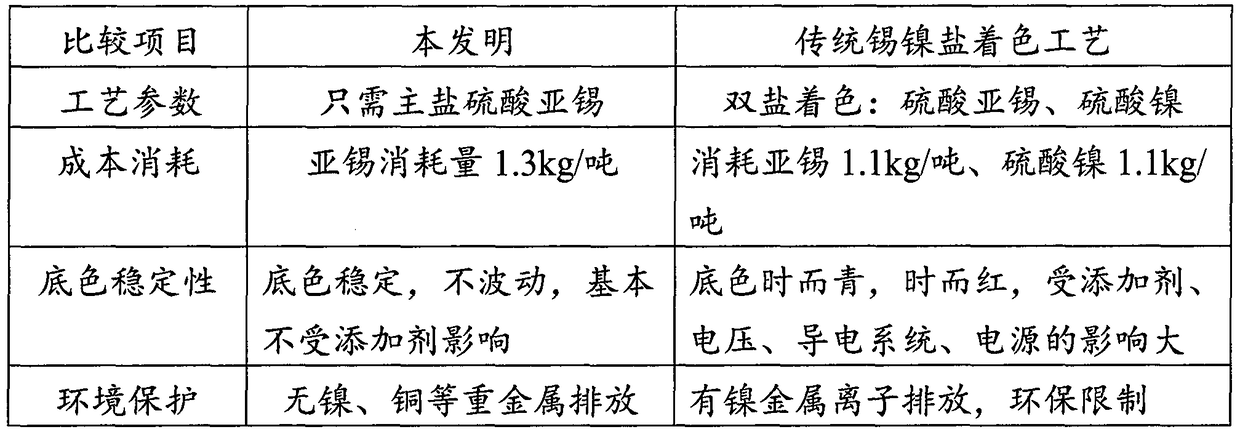

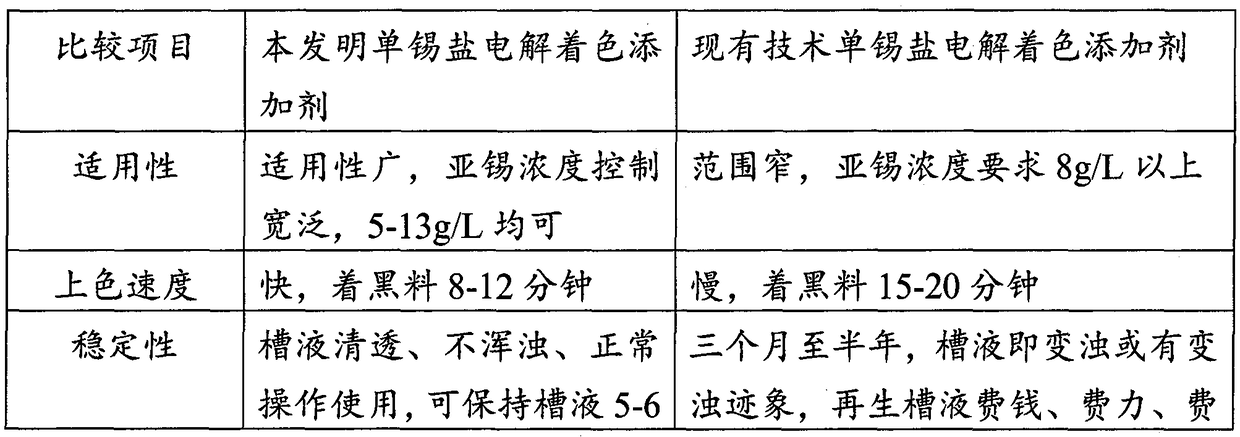

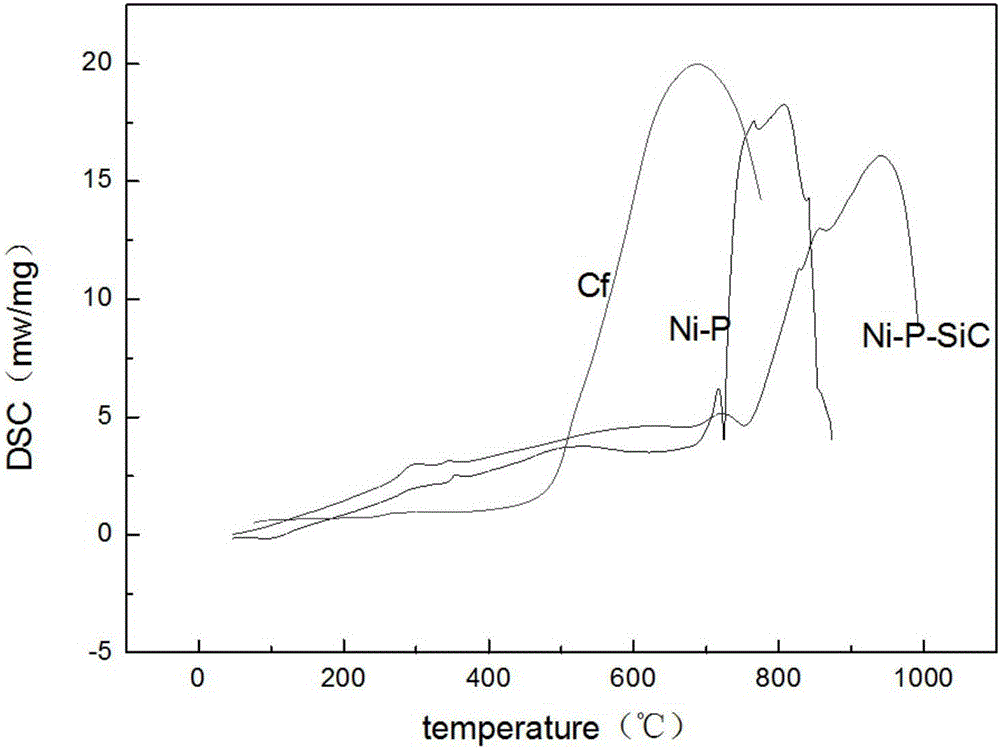

Single tin salt electrolytic coloring additive and application thereof

InactiveCN108342763AAntioxidantProtection stabilitySurface reaction electrolytic coatingZinc phosphateElectrolysis

The invention discloses a single tin salt electrolytic coloring additive. The single tin salt electrolytic coloring additive comprises a complexing agent, a buffer agent, an antioxidant and a surfactant, wherein the antioxidant comprises ferrous sulfate; the single tin salt electrolytic coloring additive also comprises an auxiliary agent containing ferrous sulfate; the auxiliary agent comprises modified amino amide zinc phosphate. The single tin salt electrolytic coloring additive disclosed by the invention has good comprehensive performances, solves the problem that nickel must take part in the reaction in an electrolytic coloring process, and is stable in groove liquid and quick and uniform to color, and the cost can be lowered effectively. Moreover, the single tin salt electrolytic coloring additive is low-carbon, energy-saving and green and environment-friendly, and process and product quality consistent to those of a double salt system can be obtained.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

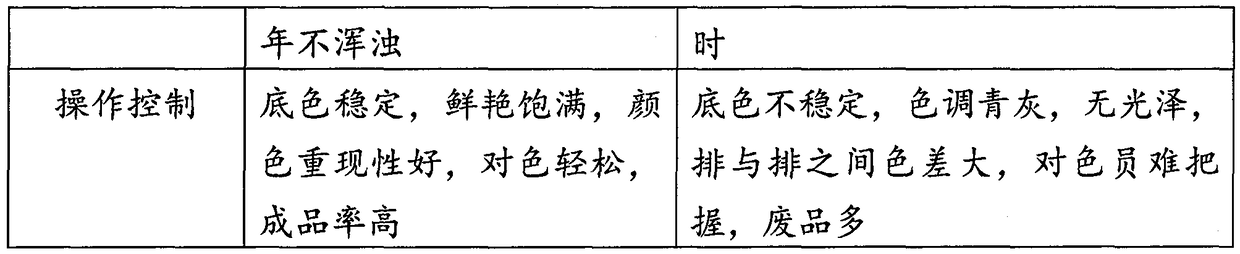

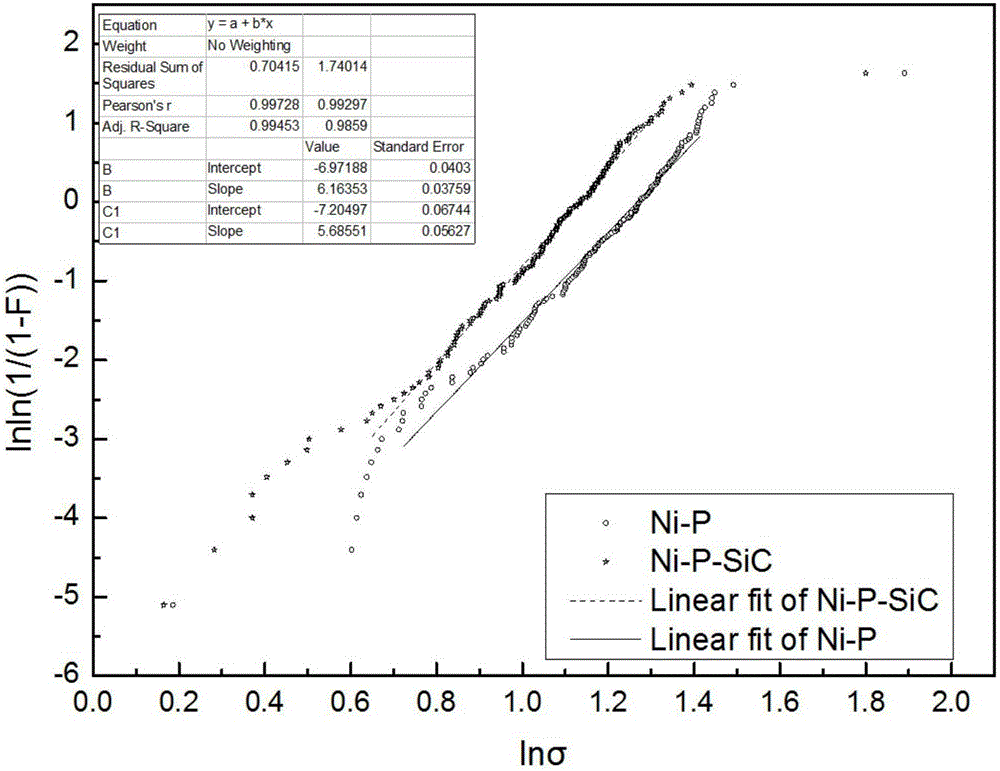

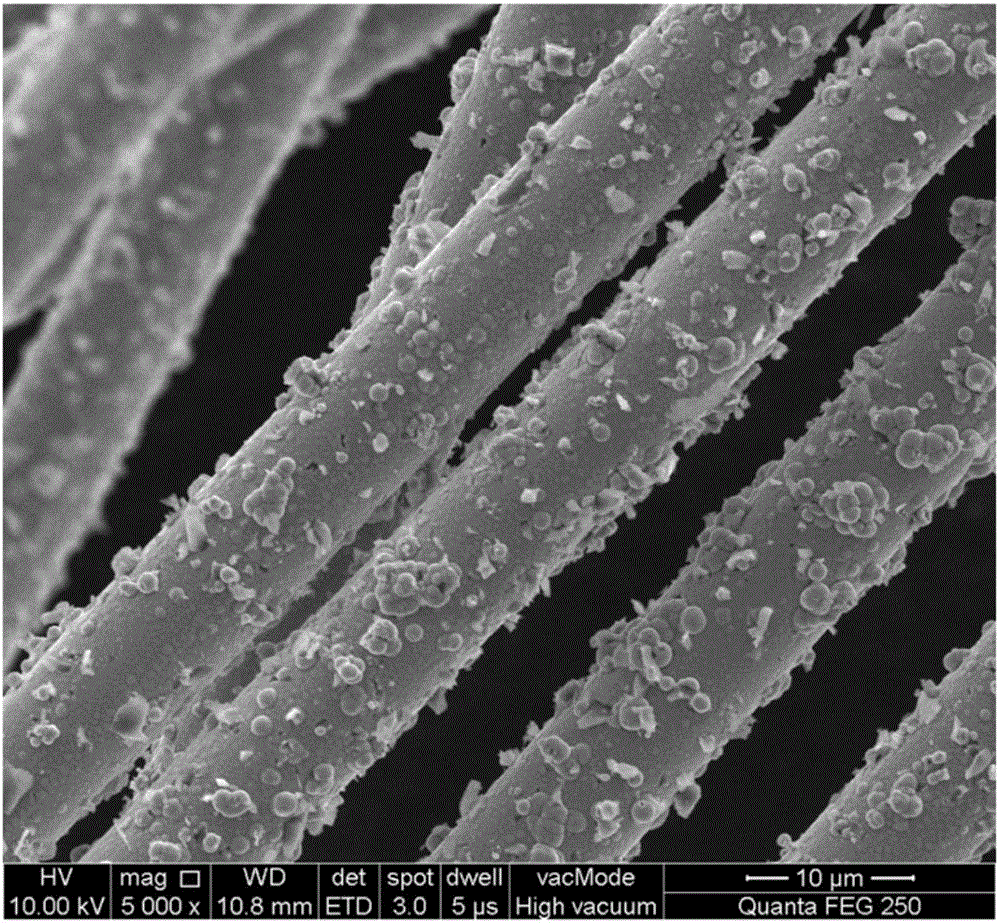

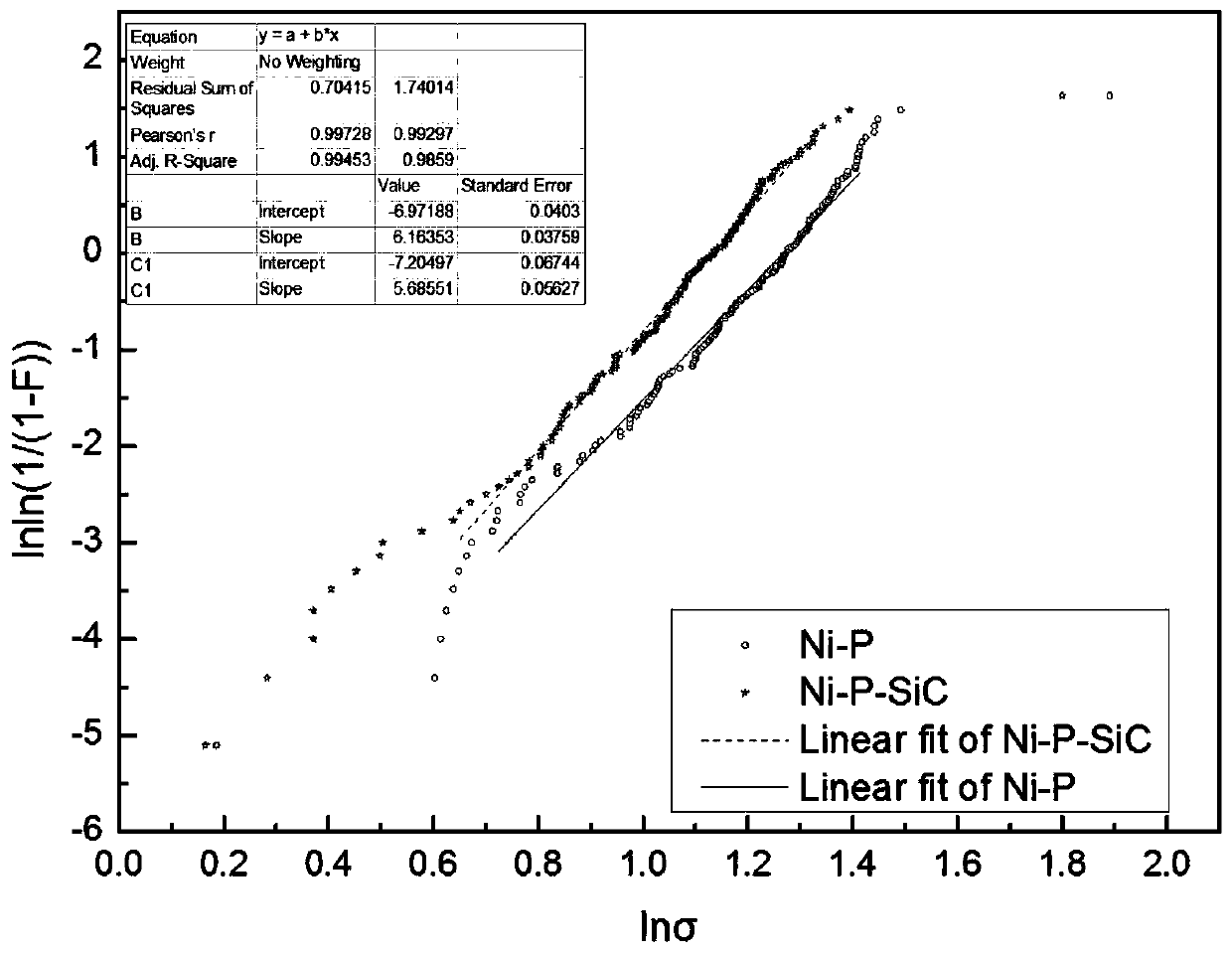

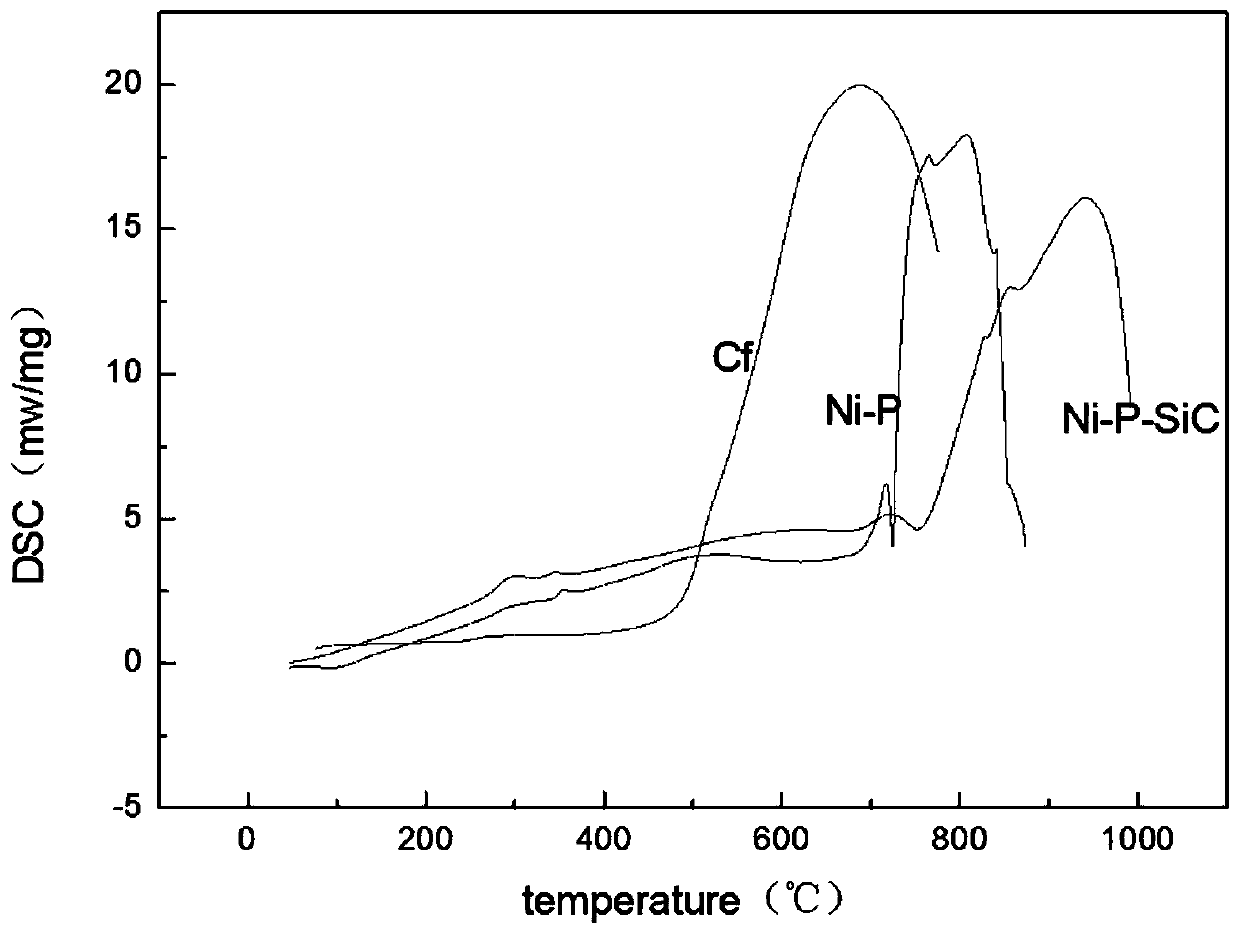

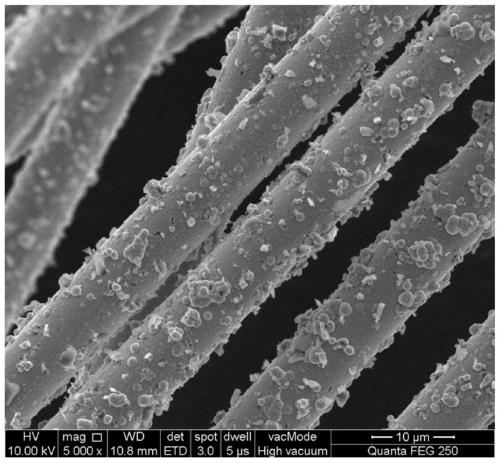

Modified carbon fiber containing Ni-P-SiC (titanium diboride) composite plating layer and preparation and application thereof

ActiveCN106544656AImprove oxidation resistanceEffective protectionLiquid/solution decomposition chemical coatingFiberChemical plating

The invention discloses a modified carbon fiber containing a Ni-P-SiC (titanium diboride) composite plating layer and a preparation method and application thereof. The modified carbon fiber consists of a carbon fiber and a Ni-P-SiC composite plating layer, a Ni-P-TiB2 composite plating layer or a Ni-P-SiC-TiB2 composite plating layer on the surface thereof. The preparation method comprises the following steps: the surface of the carbon fiber is put in chemical plating liquid for chemically plating the Ni-P-SiC, Ni-P-TiB2 or Ni-P-SiC-TiB2 composite layer to obtain the compact and uniform composite plating layer after pretreatment of degumming, roughening, neutralization, sensitization, activation, reduction and peptization; the bonding force of the composite plating layer and the carbon fiber is high; the compatibility of the modified carbon fiber and a metal matrix is excellent; the dispersibility in the metal matrix is excellent; a carbon fiber reinforced metal base composite material with good mechanical performance, stable performance and good reliability can be prepared; and the preparation method of the modified carbon fiber is simple and low in cost, and facilitates industrial production.

Owner:CENT SOUTH UNIV

Compressed small-cake-shaped herb tea processing method

InactiveCN104522255AQuality assuranceReduce labor intensityPre-extraction tea treatmentTea substituesEngineeringMoisture

The invention discloses a compressed small-cake-shaped herb tea processing method. A processing process characterized by physical modes of material mixing, moisture regaining, compression, shaping and the like is adopted, drying is avoided, the process is simplified, no binding agent is needed, direct compression and forming are achieved, safety and sanitation are achieved, energy consumption is lowered, efficiency is improved, the quality and the characteristics of color, aroma and taste of original herb tea are maintained, particles are made into cakes in a low basis weight and small specification mode, and the tea can be stored for a long time and convenient to carry and use. The invention further provides a formula of common herb tea and proper basis weight specification.

Owner:GUANGXI POLYTECHNIC

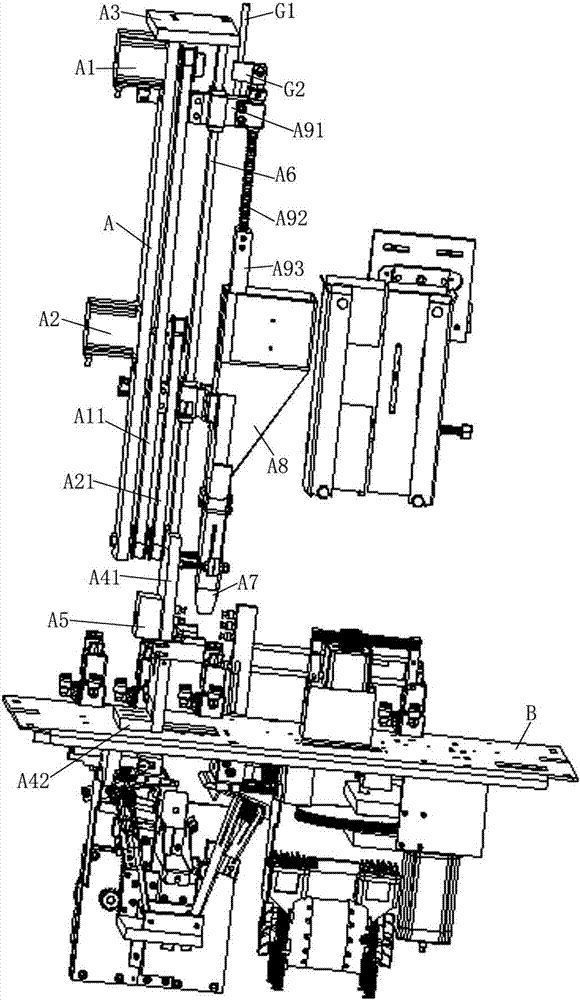

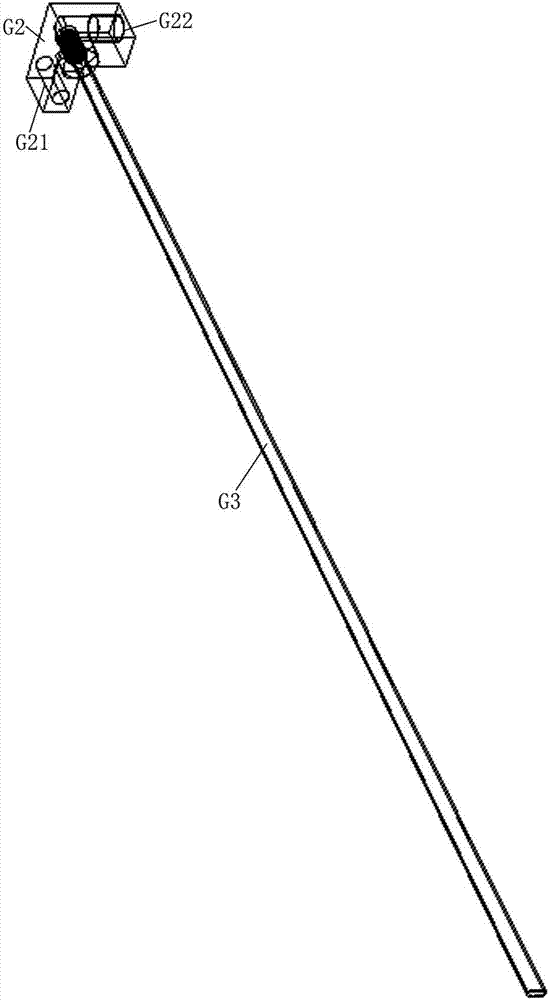

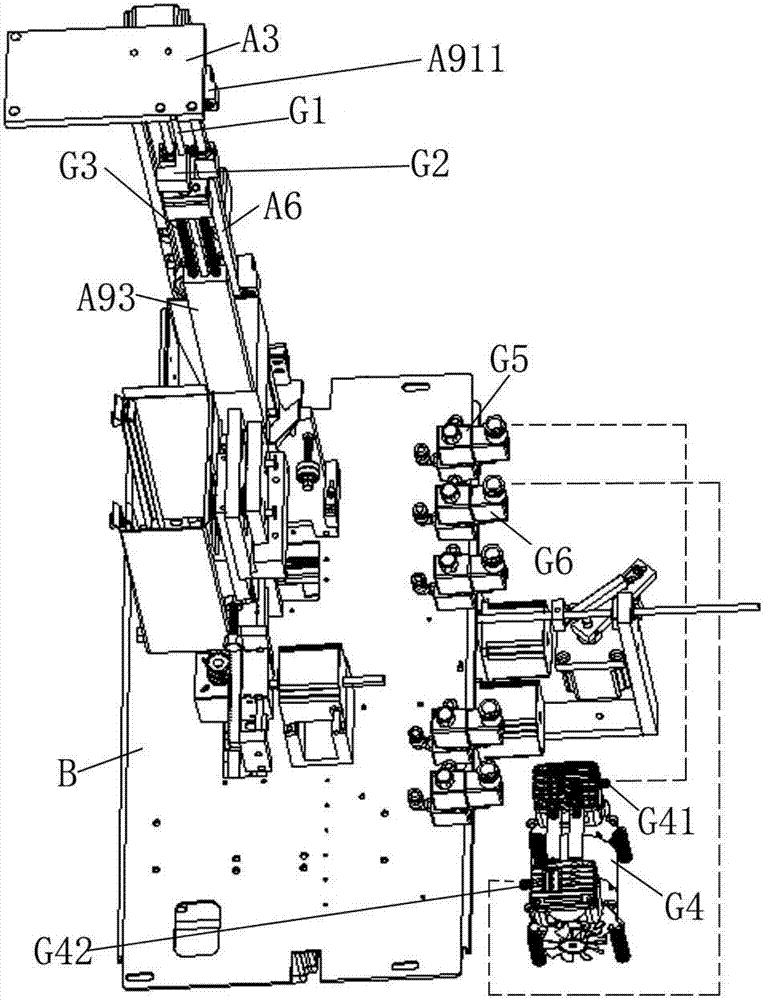

Needle type vacuum pumping and heat seal coding device used for pure electric shaping packaging machine

ActiveCN107512426AHigh speedWill not adsorbPackaging by pressurising/gasifyingWrapper twisting/gatheringVacuum pumpingEngineering

The invention discloses a needle type vacuum pumping and heat seal coding device used for a pure electric shaping packaging machine. A bag body seal coding system is arranged at the lower end of a needle suction type bag body vacuum pumping system, the bottom end of a strip-shaped needle type ventilation pipe in the needle suction type bag body vacuum pumping system can be inserted into a bag body and makes contact with the surface of tea leaves in the bag body, a bag opening of the bag body and the strip-shaped needle type ventilation pipe inserted into the bag body can be clamped by a seal strip mechanism in the bag body seal coding system at the same time, when the vacuum pumping procedure of the bag body is finished, the bottom end of the strip-shaped needle type ventilation pipe in the needle suction type bag body vacuum pumping system is pulled out upwards and enters the tea foam blowing work, and the bag body seal coding system carries out dual-side heat seal and date code coding work on the bag opening of the bag body subject to vacuum pumping work finally. The device has the beneficial effects that the structure is novel, the vacuum pumping speed of the bag body is higher, vacuum pumping is more thorough, the expiration date of filler in the bag body is longer, the tea foam blowing effect is ideal, and the practicability is higher.

Owner:福建省安溪县兴安金属有限公司

Material for non-asbestos copper fibre brake disc

The invention relates to a non-asbestos copper fiber brake plate material, composed of phenolic resin, frication dust, butadiene acrylonitrile rubber, alumina, chromite, feldspar, cut copper fiber, needle shape wollastonite powder, tire powder, magnesia and lignin fiber; the weight percentages of the ingredients are as follow: phenolic resin 8-12%, frication dust5-15%, butadiene acrylonitrile rubber2-5%, alumina5-10%, chromite15-25%, feldspar5-8%, cut copper fiber6-8%, needle shape wollastonite powder10-15%, tire powder15-20%, magnesia2-5% and lignin fiber15-20%. The non-asbestos fiber brake plate with a copper substrate is of high brake performance, stable friction coefficient, high thermal conduction, good head dissipation performance in the rubbing process and good plasticity and has no harm to dualization; the copper substrate has small binding affinity to oxygen and is slow to oxidate in air.

Owner:重庆银角制动器有限公司

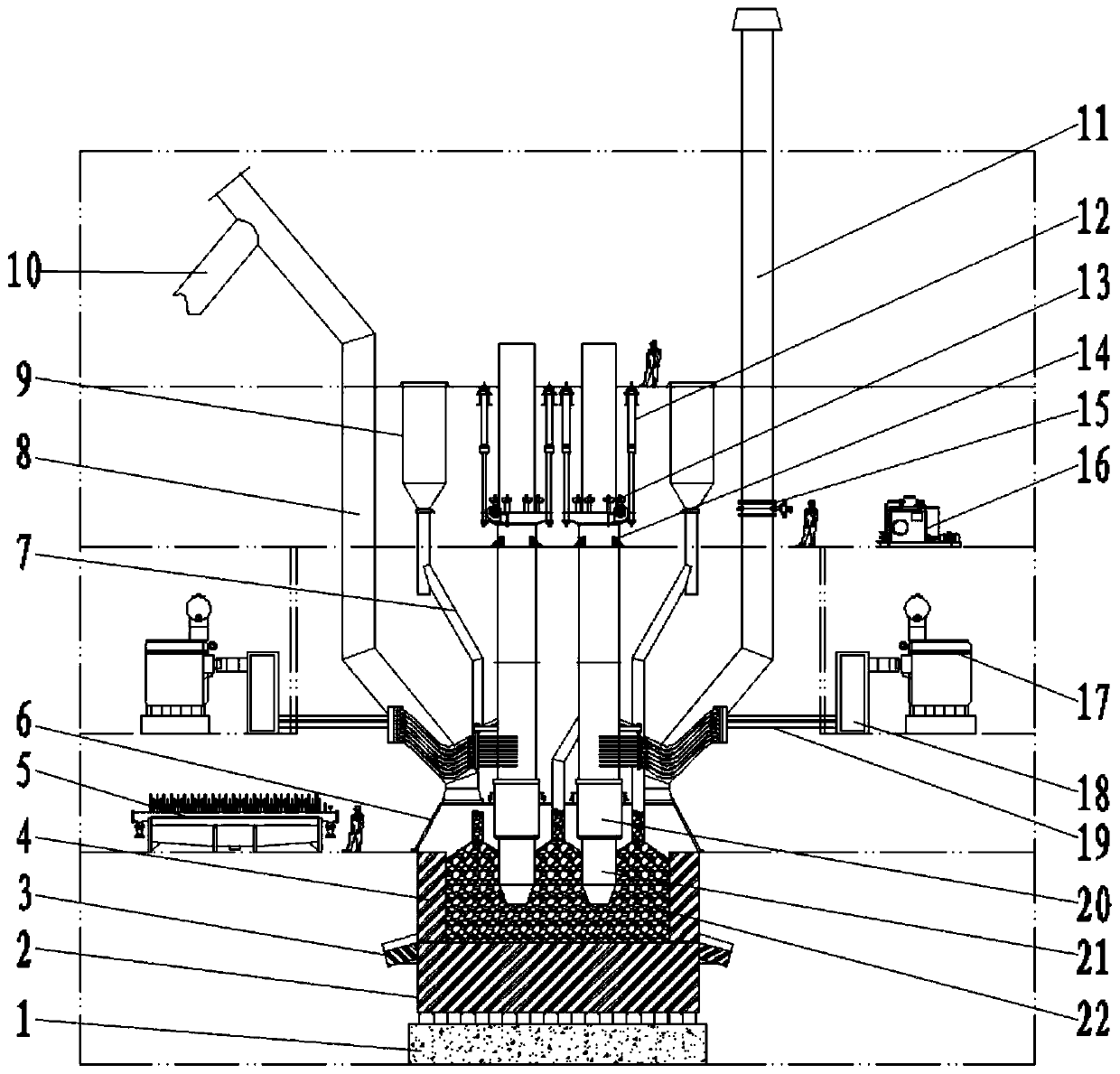

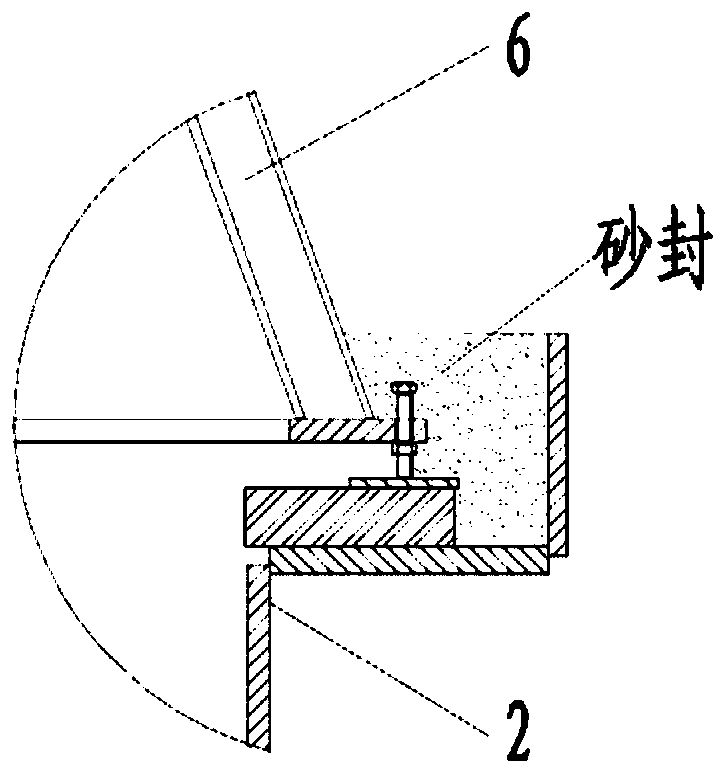

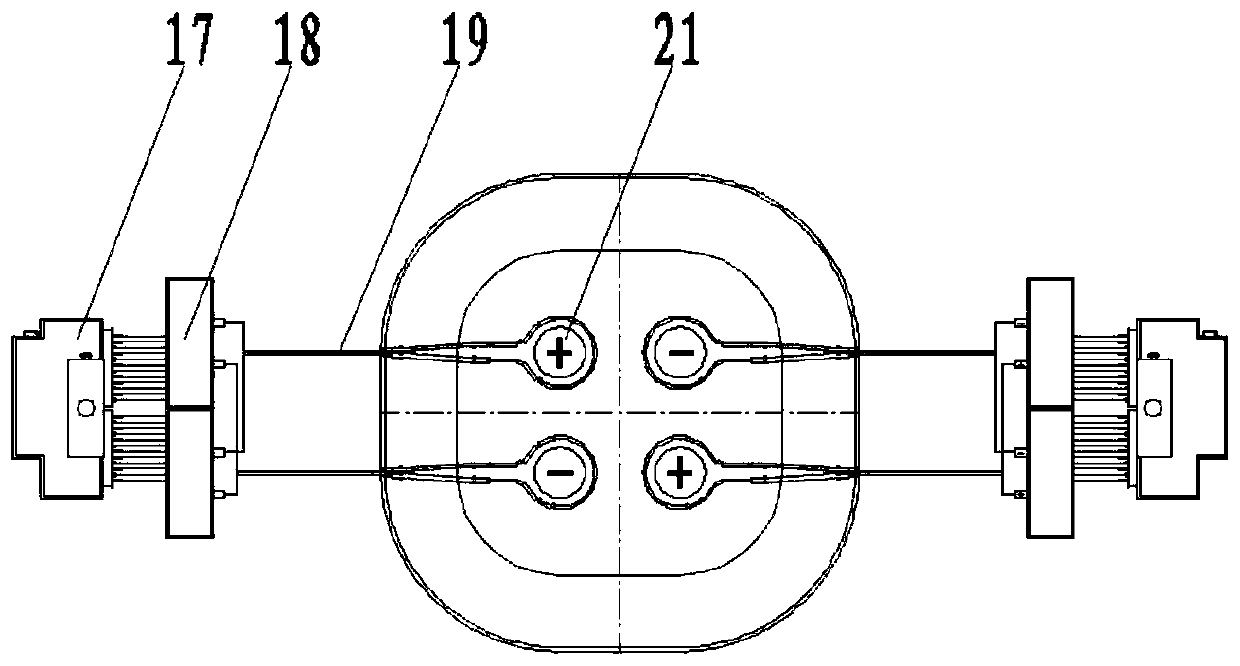

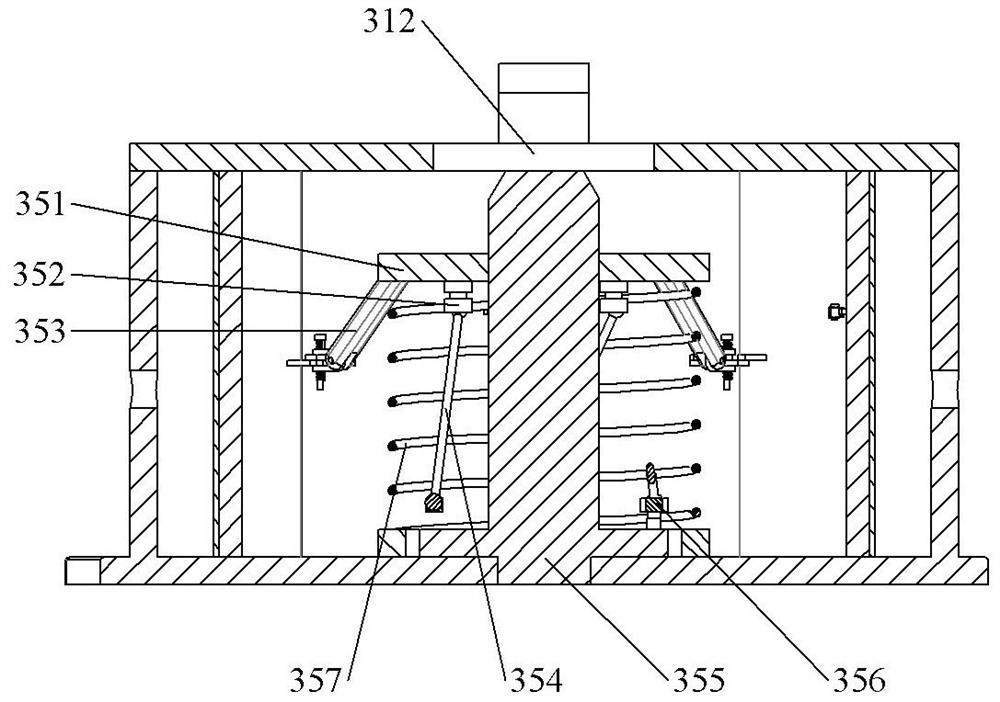

Closed non-fixed anode direct-current submerged arc furnace

PendingCN110081703AImprove use valueReduce energy consumptionElectric discharge heatingIncreasing energy efficiencyFailure rateFlue gas

The invention provides a closed non-fixed anode direct-current submerged arc furnace. The closed non-fixed anode direct-current submerged arc furnace comprises a furnace body, a furnace cover, an electrode column system, a feeding system, a flue gas leading-out system, a power supply system, a cooling water system and a hydraulic system, wherein the furnace body is used for containing furnace burden, the electrode column system is used for heating and melting the furnace burden by utilizing a direct-current arc, comprises a cathode and an anode, and the cathode and the anode can freely adjustthe depth inserted into the furnace burden; and the furnace cover used for ensuring the sealing of the furnace body is arranged above a furnace shell of the furnace body, and the furnace cover and thefurnace shell are subjected to sealing treatment. According to the closed non-fixed anode direct-current submerged arc furnace, a submerged arc furnace gas with relatively high CO concentration is generated after the submerged arc furnace is sealed, can be used as fuel for power generation, roasting, hot-blast stove and the like after being purified and recycled, so that the utilization value isextremely high, and the comprehensive energy consumption can be reduced; and almost no air enters a hearth, the oxidation of the electrode is slow, the loss is low, both the cathode and the anode canmove up and down, are inserted into the solid furnace burden, not in direct contact with a high-temperature molten liquid, the structure is simple, the equipment is reliable in operation and failure rate is low.

Owner:大连重工机电设备成套有限公司 +1

Grid section used for sintering acid mine

The invention relates to a grid section used for sintering acid mine. The grid section comprises the following components in percentage by weight: 1.1-1.3% of C, 26.0-28.0% of Cr, 0.3-0.5% of Mo, 1.0-1.5% of Ni, 1.0-1.5% of Si, 0.5-1.0% of Mn, 0.10% of Ti, 0.05-0.15% of Re, 1.0-2.0% of Al and the balance of Fe. The grid section disclosed by the invention is totally suitable for acid mine sintering working conditions and satisfies use requirements, the service life of the grid section is prolonged to more than 12 months from less than 3 months, and therefore the use cost of the grid section isgreatly lowered. Meanwhile, replacement frequency of the grid section can be reduced, the labor intensity of operators is lowered, downtime for replacing the grid section is shortened, and productionefficiency is improved.

Owner:JINAN JIGANG IRON ALLOY FACTORY

Preparing method of polyamide conductive fiber

InactiveCN110528105AImprove conductivityLarge specific surface areaElectroconductive/antistatic filament manufactureTransportation and packagingFiberPolyamide

The invention relates to a preparing method of a polyamide conductive fiber, and belongs to the technical field of fiber materials. With graphite as the carbon source, graphene grows on the surface ofsuperfine silver powder through an in-situ chemical vapor deposition method to serve as the conductive dopant, and with polyamide as the raw material, the polyamide conductive fiber is prepared through electrostatic spinning; the graphene is a single-atom-layer two-dimensional crystal material formed by connecting carbon atoms through sp2 hybridization, and due to the special structure, the graphene has high conductivity which other materials cannot have; the prepared conductive dopant is doped into the polyamide, and the polyamide conductive fiber is prepared through electrostatic spinning;when the content of the conductive dopant in the fiber reaches a certain value (percolation threshold), a three-dimensional mesh-shaped structure starts to be formed, a conductive channel is formed, and the percolation phenomenon happens; at the moment, the fiber resistivity is suddenly reduced, and therefore a polymer becomes a semiconductor or a conductor.

Owner:宁波宏翌能源科技有限公司

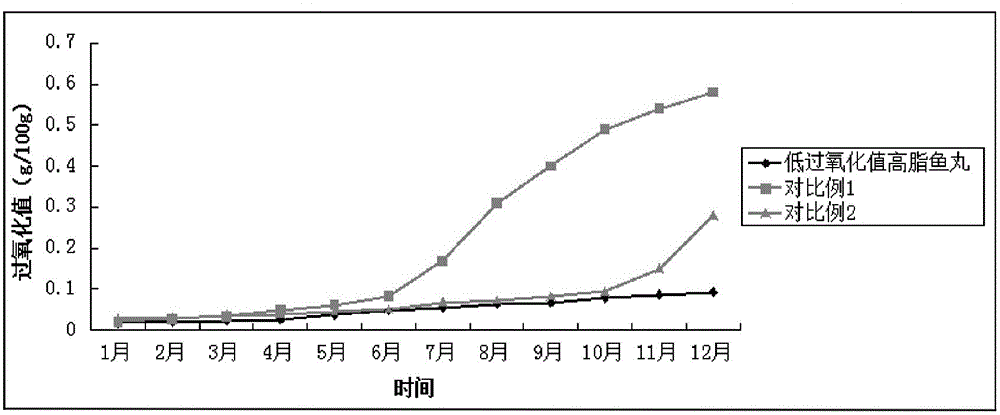

Low-peroxide-value and high-fat fish ball added with seaweed concentrate and preparation method of fish ball

InactiveCN104872726AUnique flavorExtended shelf lifeFood ingredient as antioxidantFood ingredient as flavour affecting agentFlavorPhosphate

The invention discloses a low-peroxide-value and high-fat fish ball added with a seaweed concentrate and a preparation method of the fish ball. The fish ball mainly consists of the following components in parts by weight: 50-100 parts of frozen minced fillet, 5-10 parts of a seaweed concentrate, 15-30 parts of grease, 10-20 parts of water, 0.03-0.5 part of composite phosphate, 0.5-1.5 parts of table salt, 0.1-0.3 part of seasoning and the balance of accessories. The low-peroxide-value and high-fat fish ball added with the seaweed concentrate, which is disclosed by the invention, is low in peroxide value, long in shelf life and rich in nutrition; by introducing the seaweed concentrate which is combined with the fish ball in the preparation process of the high-fat fish ball, fat oxidation is controlled and subsequent quality issue of the high-fat fish ball caused by the fat oxidation is solved, so as to add flavor of the high-fat fish ball, enrich taste and improve the quality of the finished product; and meanwhile, the comprehensive utilization of the seaweed is promoted as well.

Owner:FUJIAN ANJOY FOODS CO LTD +1

'Yanhuning' frozen-dried powder injection and its preparation method

ActiveCN100500145CStable pH environmentSlow oxidationPowder deliveryOrganic active ingredientsPhosphateAntioxidant

The invention discloses a freeze dried injection of potassium sodium dehydroandrographolide succinate which is prepared from potassium sodium dehydroandrographolide succinate, ionic cushion pairs and anti-oxidizing agents, the preferred ionic cushion pairs being phosphate cushion pairs, and the antioxidant can be L-cysteine hydrochloride.

Owner:HARBIN ZHENBAO PHARMA

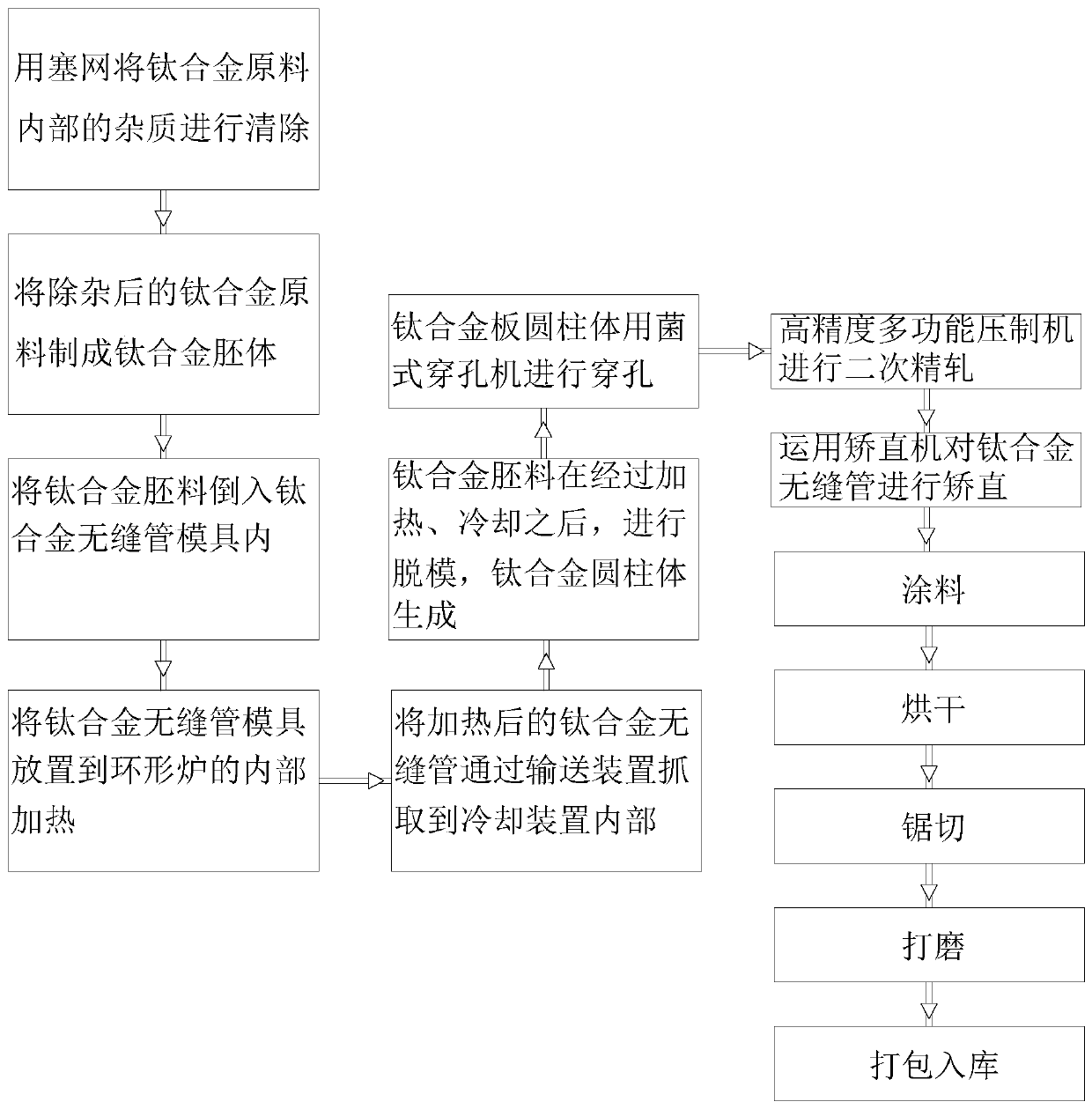

Production process of hot-rolled large-caliber thin-wall titanium alloy seamless tube

InactiveCN110586653AReduce consumptionReduce power consumptionMetal rolling arrangementsHydrogenAdditive ingredient

The invention relates to the technical field of titanium alloy seamless tubes and discloses a production process of a hot-rolled large-caliber thin-wall titanium alloy seamless tube. The technologicaloperation process of the production process mainly comprises the following steps of A, an operator removes impurities in a titanium alloy material through a clogging screen; B, manufacturing the impurity removed titanium alloy material into a titanium alloy blank; C, pouring the titanium alloy blank into a seamless tube mold; D, just placing the titanium alloy seamless tube mold into an annular furnace to be heated; E, grabbing the heated titanium alloy blank seamless tube into a cooling device through a conveying device; F, conducting demolding after titanium alloy ingredients are subjectedto heating and cooling to generate a solid titanium alloy cylinder; and G, conducting fixing on the solid titanium alloy cylinder through a machining lathe. Through the production process of the hot-rolled large-caliber thin-wall titanium alloy seamless tube, the problems that titanium has a reaction with carbon, hydrogen, nitrogen and oxygen at high temperature, the organization structure of thetitanium is changed, the physical and chemical characteristics of the titanium are affected and the using requirements can be hardly met are solved.

Owner:XINPENGYUAN INTELLIGENT EQUIP GRP

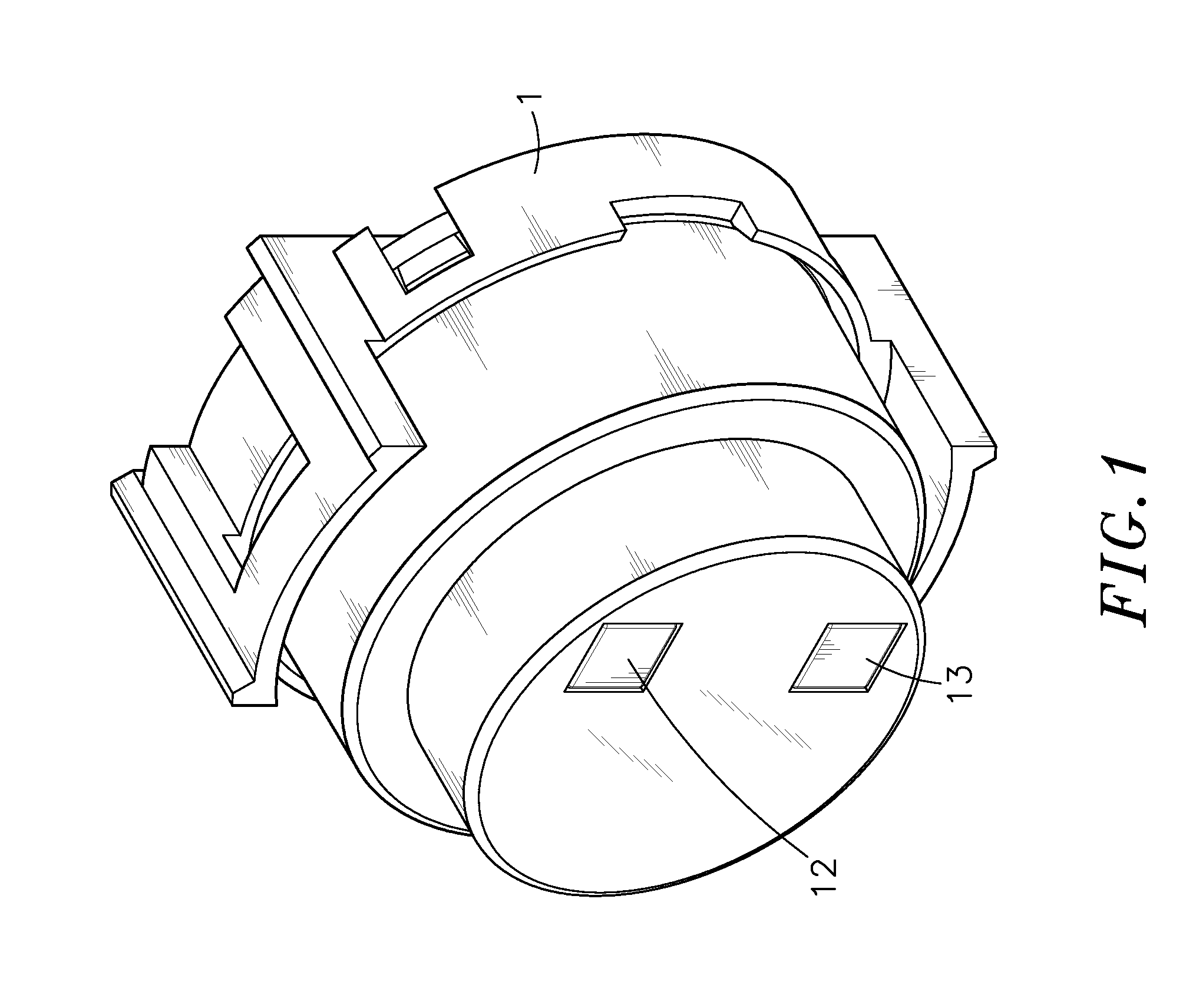

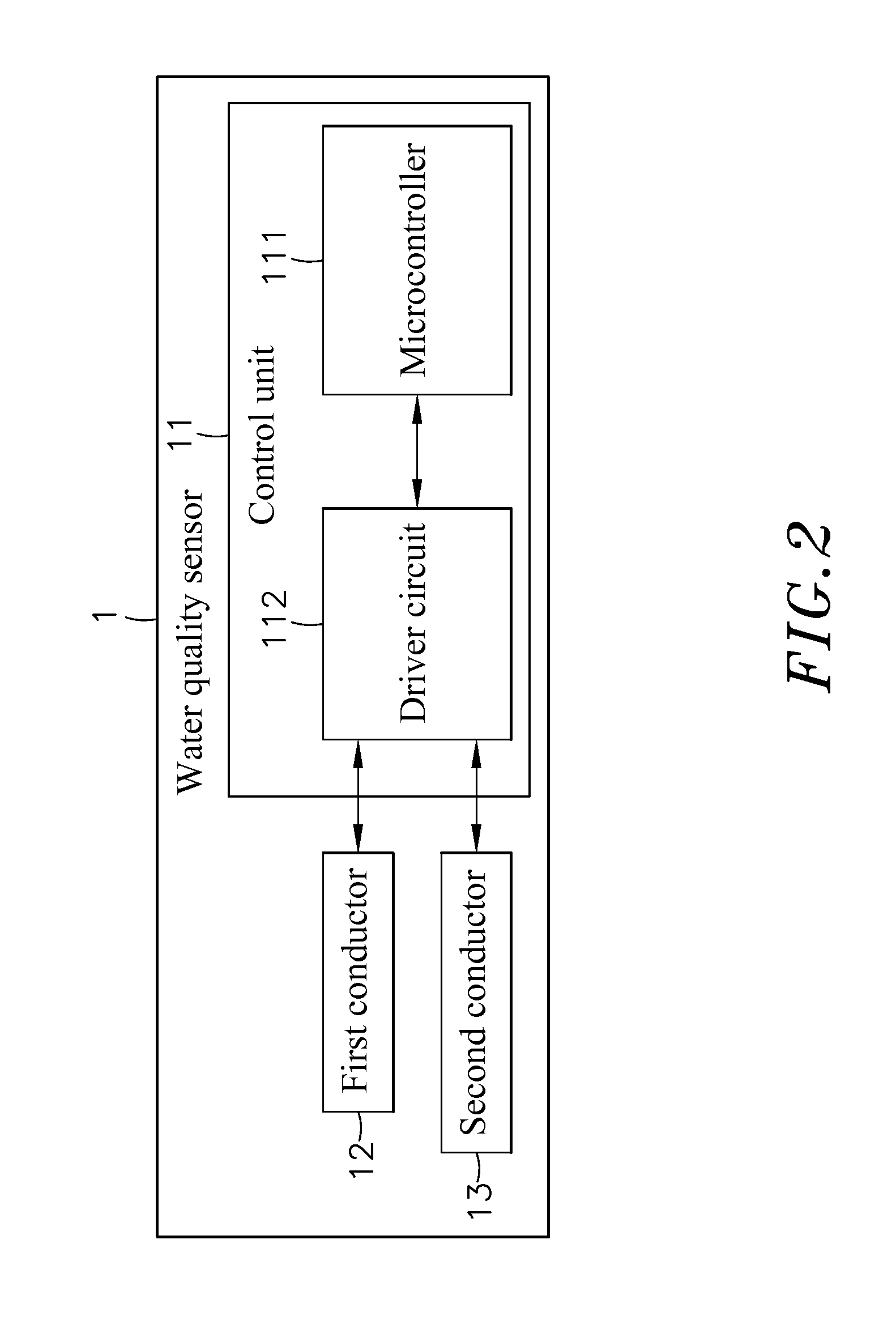

Conductivity measurement method that slows down conductor oxidation

InactiveUS20160069830A1Prolong lifespanSlow oxidationComponent separationAutomatic washing/rinsing machine detectionEngineeringElectrical conductor

A conductivity measurement method for measuring the conductivity of a fluid in a washing chamber in an electrical washing machine using a water quality sensor consisting of a control unit and first and second conductors by alternatively changing the electric potential of the first and second conductors and repeatedly measuring the conductivity of the fluid in the washing chamber between the first and second conductors upon each electric potential alternation.

Owner:SOLTEAM OPTO

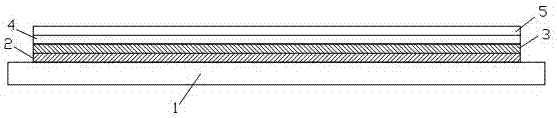

Low-loss metallized film

InactiveCN107301917ALow oxidation temperatureSlow oxidationFixed capacitor electrodesThin/thick film capacitorAntioxidant capacityPolyolefin

The present invention relates to a low-loss metallized film comprising a dielectric base film. A silver-zinc-aluminum composite metal layer is arranged on the dielectric base film, an aluminum-plated layer is arranged on the surface of the silver-zinc-aluminum composite metal layer, the surface of the aluminum-plated layer is provided with a carbon nano tube layer, the surface of the carbon nano tube layer is provided with a seal oil protective layer, the dielectric base film is a polypropylene film or a polyolefin film, and the seal oil protective layer is made of methyl silicone oil. The metalized film of the invention has high anti-oxidation ability, prevents the film from being oxidized and broken during the process of making capacitors, has low metal layer loss, and solves the problem that the metalized film heat is hard to emit resulting in the continuous oxidative breakdown. The invention also discloses a processing method of the above low-loss metallized film.

Owner:ANHUI NINGGUO HAIWEI ELECTRONICS

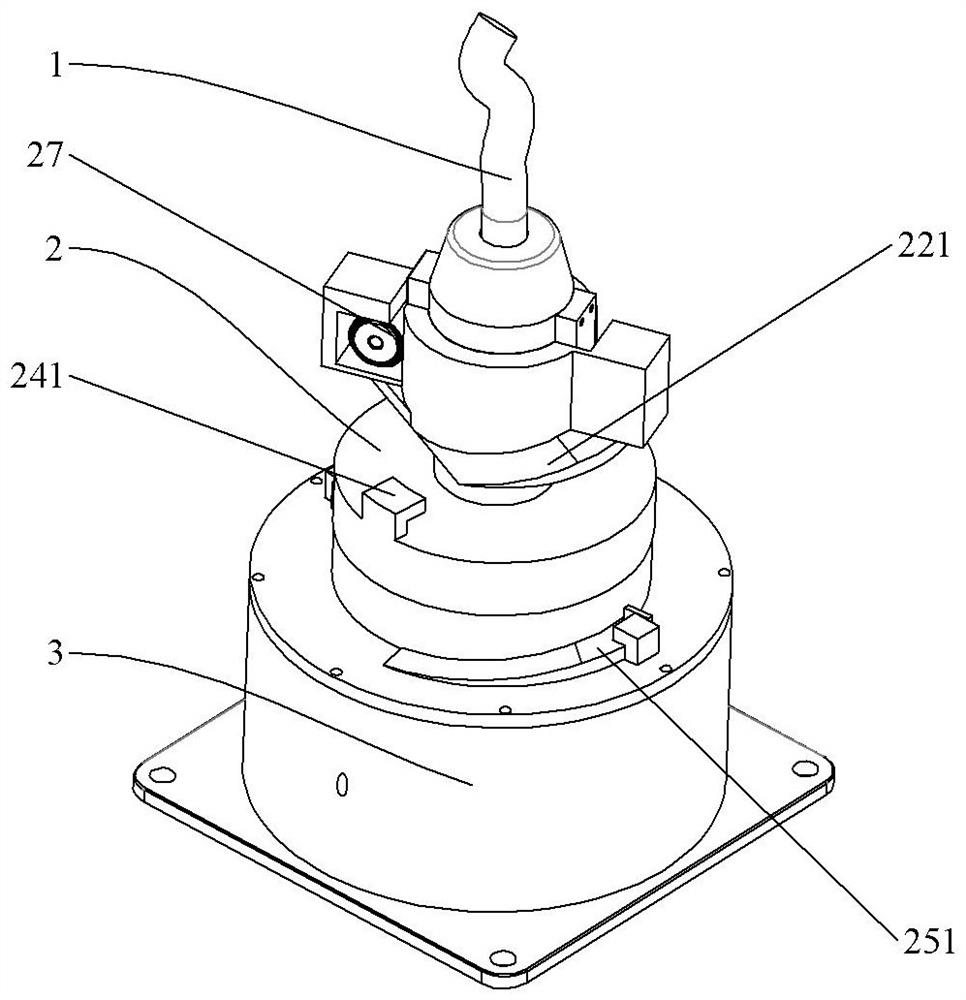

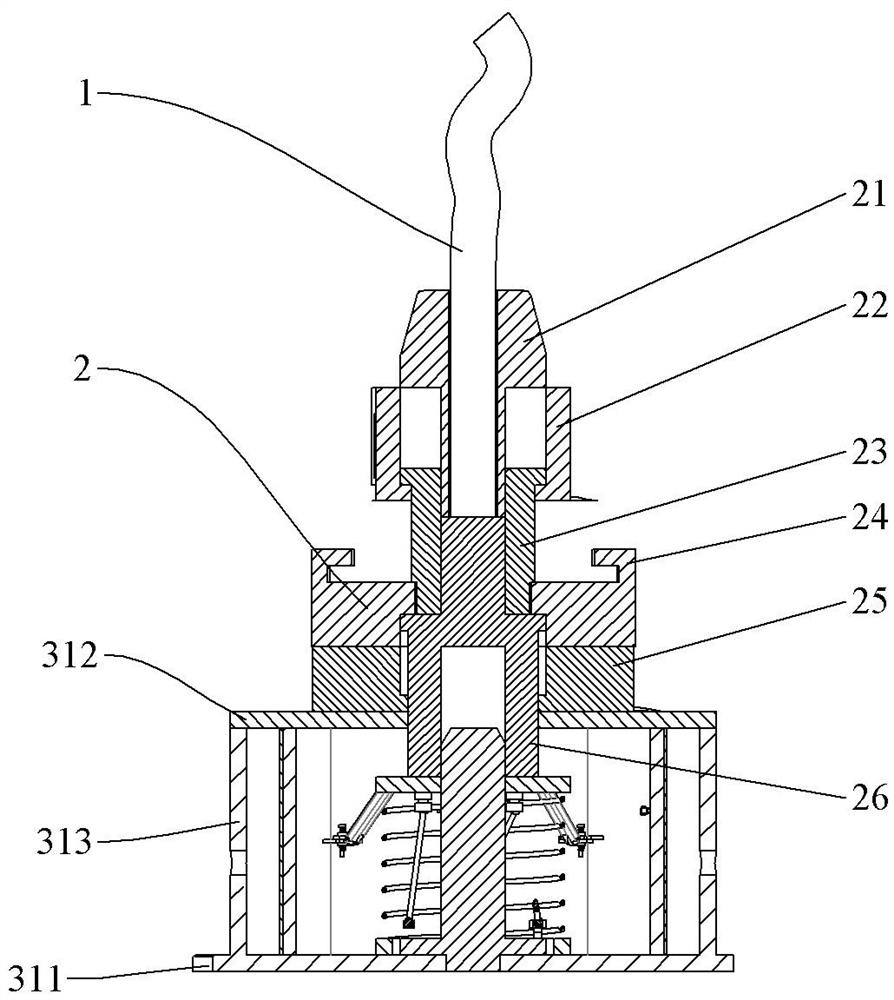

An intelligent anti-oxidation quick connector for connecting electronic equipment

ActiveCN113675663BExtend your lifeSlow oxidationSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

The invention relates to the field of power plugs, in particular to an intelligent anti-oxidation quick connector for connecting electronic equipment. The initial state of the push-pull link is configured to be inclined downward from one end to the other end. The seal ring is set on the push-pull assembly and is coaxial with the pressure plate. The other end of the push-pull link is hinged on the inner wall of the seal ring. When the connecting rod tends to be horizontal, the volume of the inner wall becomes smaller, the upper end of the sealing ring is in sealing contact with the upper sealing plate, and the lower end is in sealing contact with the lower sealing plate, so that when the plug is inserted downward from the center hole and drives the push-pull connecting rod to become horizontal, the sealing The cavity inside the ring remains sealed. Slow down the oxidation speed of the connecting plug to achieve the effect of prolonging the life of the plug.

Owner:沭阳协润电子有限公司

Method for preparing material containing amorphous iron oxide hydroxide and methods for regenerating the same

The invention relates to a method for preparing a material containing amorphous iron oxide hydroxide and two methods for regenerating the same after being used as desulfurizer. The content of the amorphous iron oxide hydroxide in the material prepared by the invention is as high as 65% to 100%, so the sulfur capacity of the material is high; and the desulfurizer in the prior art is non-regenerative or costly for regeneration, so that the desulfurizer in a large amount cannot but be dumped as waste liquid in landfills, while the amorphous iron oxide hydroxide in the material of the invention can be repeatedly regenerated and reused after the material is used as the desulfurizer, thereby solving the problems of the waste of effective resources in the original desulfurizer and the severe environmental pollution.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for removing peculiar smell of raw meat

PendingCN112931759AReduce dosageInhibit lipid oxidationNatural extract food ingredientsBiotechnologyZINC LACTATE

The invention belongs to the technical field of meat product processing, and particularly discloses a method for removing peculiar smell of raw meat. The zinc lactate and the tea leaf extract are mixed according to the proportion of (2-4): 1, the addition amount of the zinc lactate is controlled to be 85-110 mg / kg, the zinc lactate is added into the raw material meat in two times for reaction, lipid oxidation is effectively inhibited through the combined action of the zinc lactate and the tea leaf extract, meanwhile, the use amount of the tea leaf extract is also reduced, and the peculiar smell can be effectively removed for a long time. According to the invention, a layer of sodium alginate aqueous solution is sprayed on the surface of the raw meat treated by the zinc lactate and the tea leaf extract, and the sprayed sodium alginate quickly forms a film, coats the surface of the raw meat and can cover fine holes formed in the frozen storage process of the meat, so that the contact between fat and oxygen is isolated, the oxidation of lipid is further inhibited, the lipid oxidation degree of the raw material meat is obviously slowed along with the prolonging of the freezing storage time, and the peculiar smell can be effectively removed for a long time.

Owner:绵阳市米小福食品有限公司

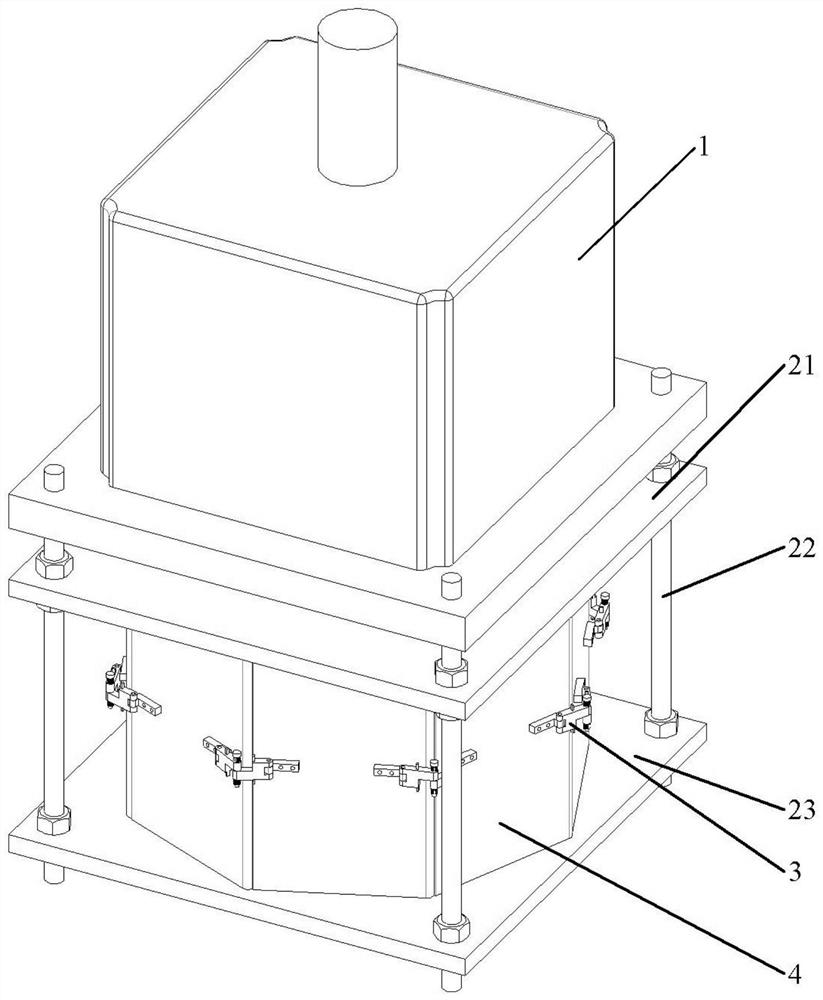

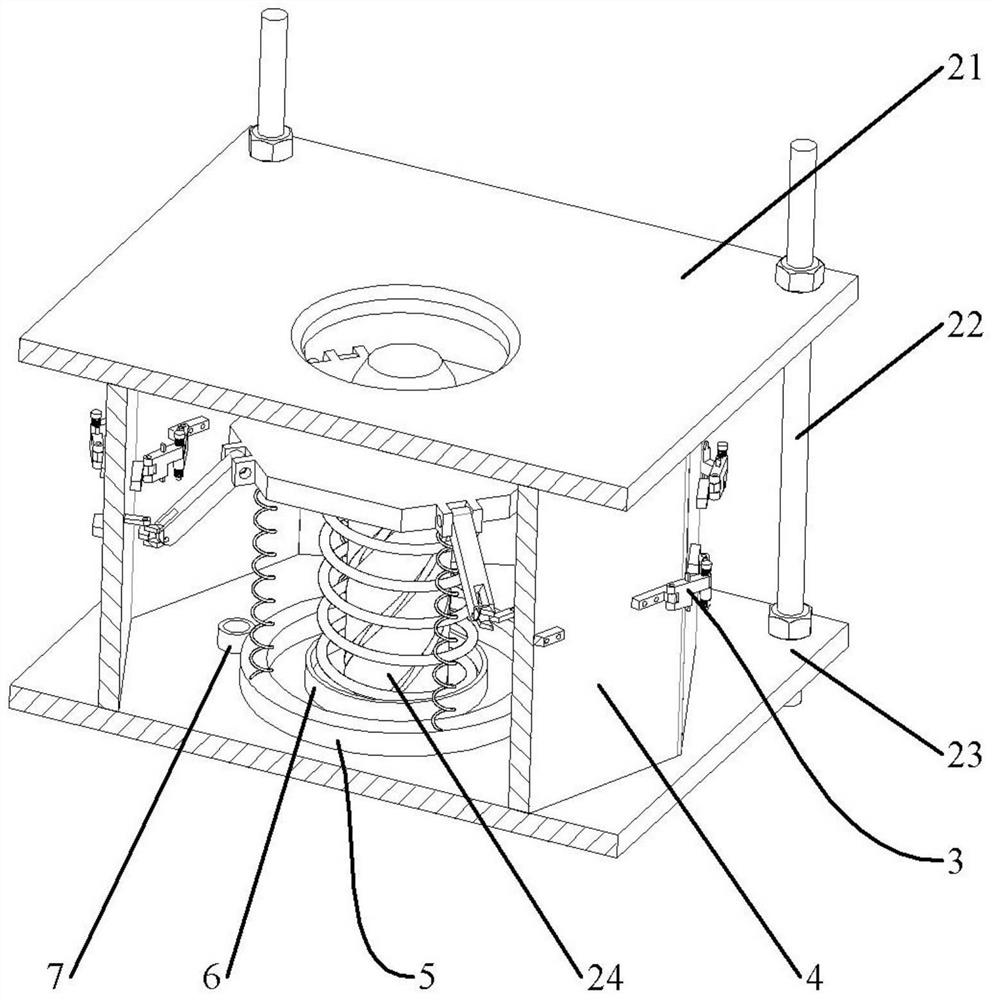

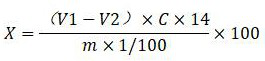

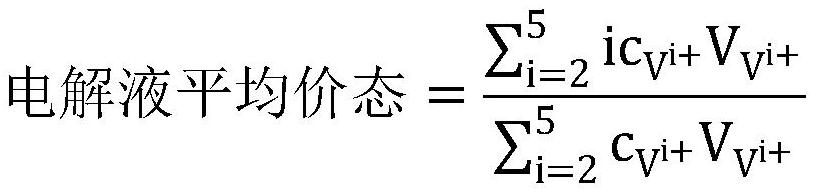

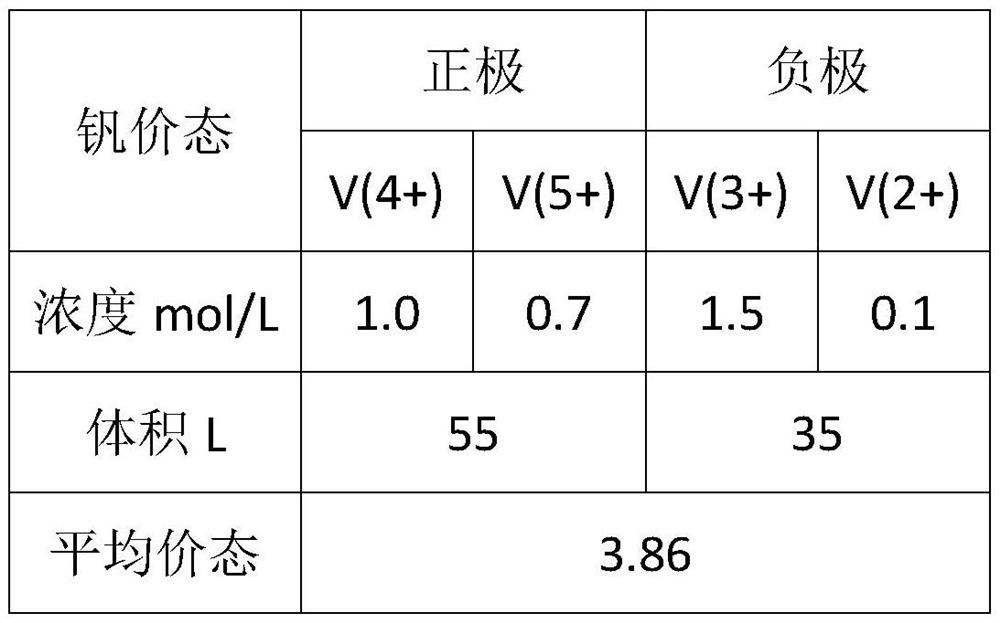

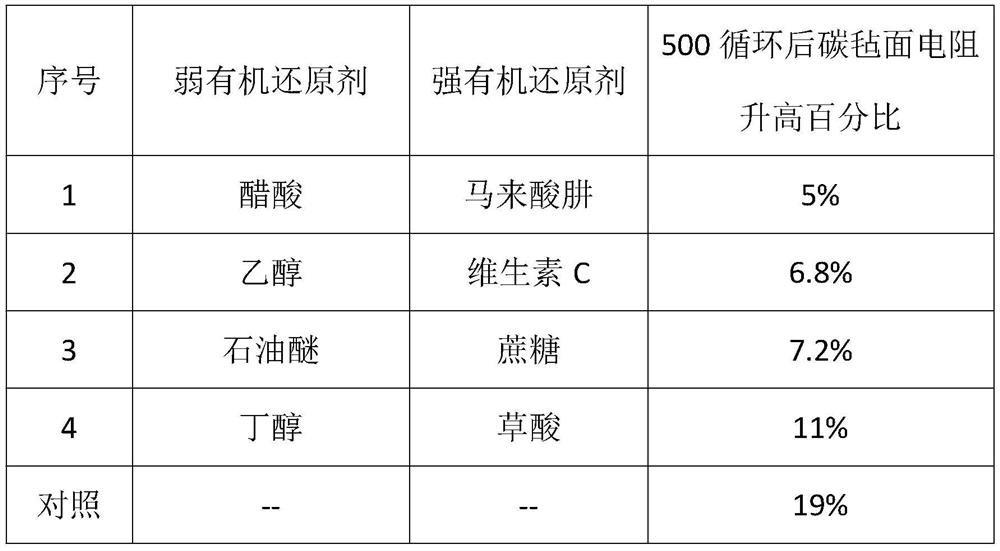

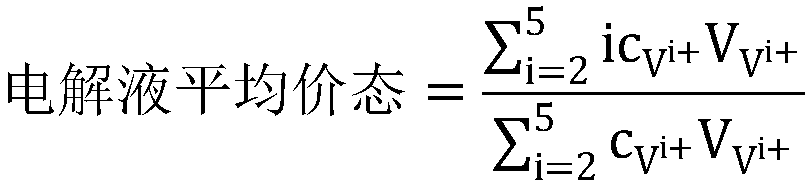

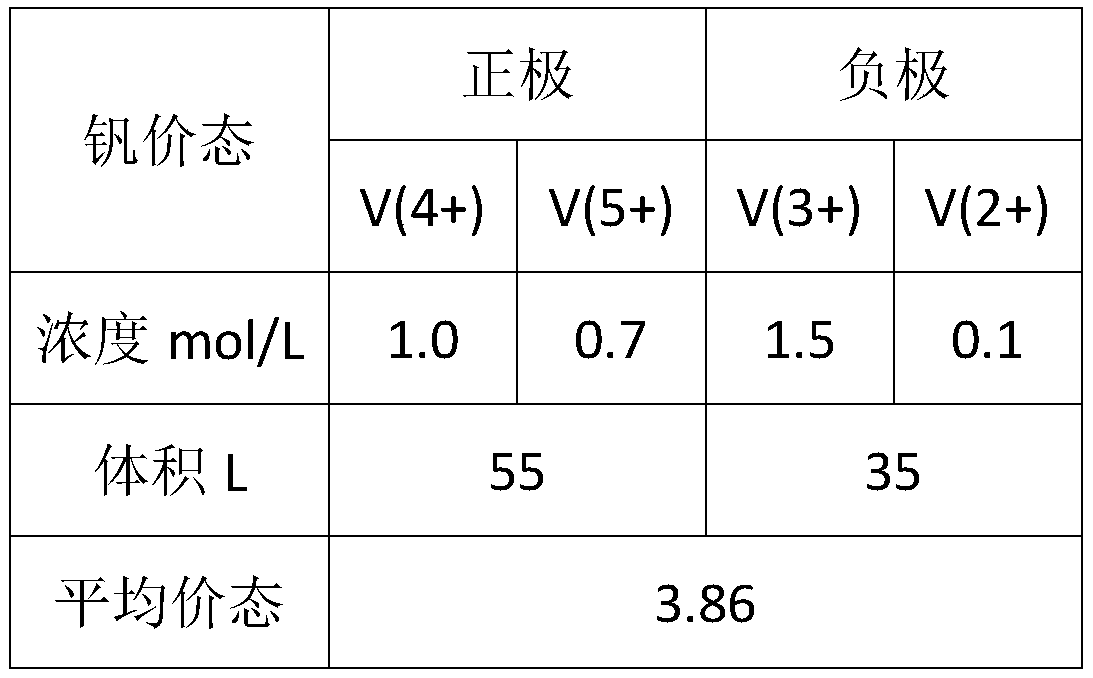

Method and system for reducing oxidation rate of flow battery electrodes

ActiveCN110729504BIncrease concentrationReduce oxidation rateRegenerative fuel cellsElectrolytic agentCarbon felt

Owner:DALIAN RONGKE POWER

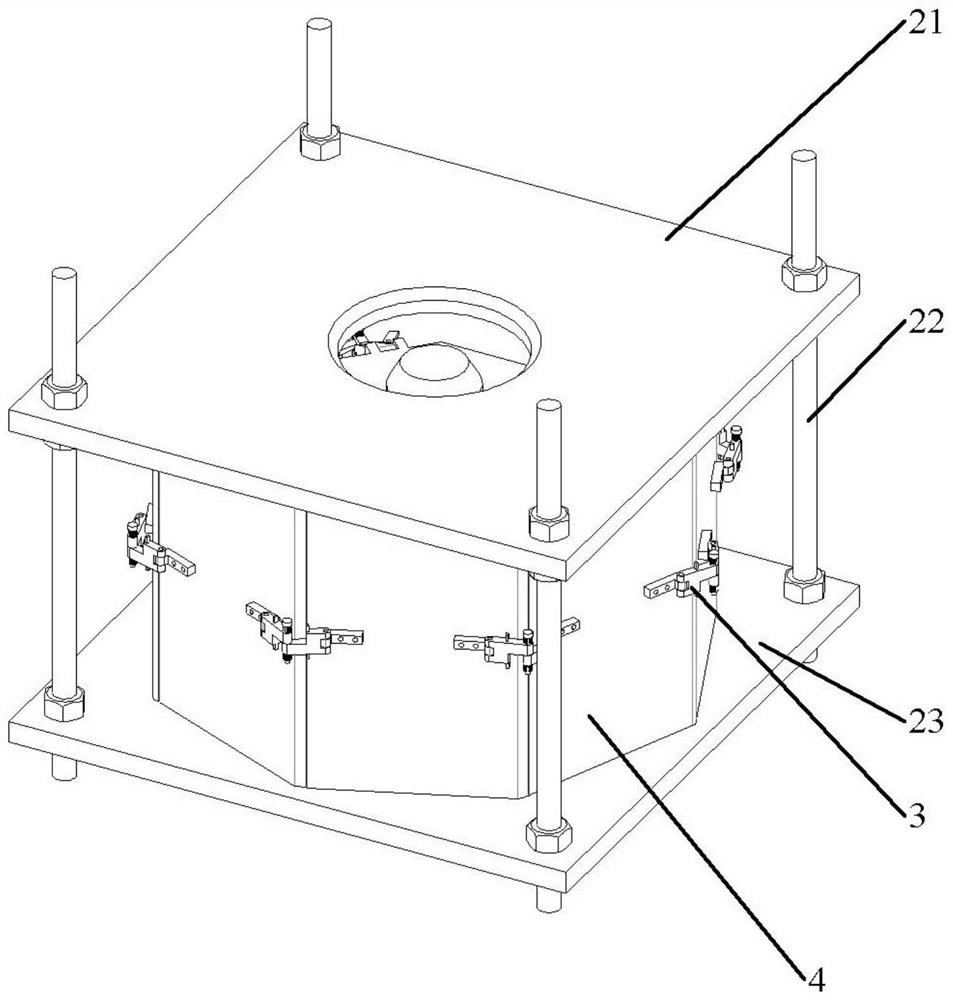

An anti-oxidation quick connector for cable installation

ActiveCN113572120BExtend your lifeReduce volumeCable junctionsCable inlet sealing meansStructural engineeringElectric cables

The invention relates to the field of cable connection, in particular to an anti-oxidation quick joint used for cable installation. The upper end of the sealing ring is in sealing contact with the upper sealing plate, and the lower end is in sealing contact with the lower sealing plate. The cross-sectional area of the sealing ring is a regular polygon in the initial state. , the internal volume becomes smaller. The plug is inserted downward into the mounting frame from the central hole and is in sealing contact with the central hole, and is set on the conductive post and contacts the outer surface of the conductive post to form a sealed space with the sealing ring, the upper sealing plate and the lower sealing plate. The push-pull assembly is arranged in the sealed space, and is configured to drive the sealing hinge point at the spaced position on the sealing ring to move outward under the extrusion of the plug sliding down, so that the volume in the sealed space becomes smaller and the sealed space becomes smaller. The gas is discharged from the one-way valve. The oxidation speed of the connection plug is slowed down to achieve the effect of extending the life of the plug.

Owner:启东晶尧光电科技有限公司

Luminous epoxy paint and preparation method thereof

ActiveCN102876199BLong glow timeImprove performanceLuminescent paintsEpoxy resin coatingsCompound aEpoxy

The invention discloses a luminous epoxy paint and a preparation method thereof. The paint is obtained by compounding a component A and a component B, wherein the component A comprises the following components by weight percent: 40-55% of epoxy resin, 40-55% of fluorescent powder, 2-8% of thickening agent, 0.1-0.6% of defoaming agent and 0.1-0.6% of levelling agent; the component B comprises the following components by weight percent: 40-55% of curing agent, 40-55% of fluorescent powder, 2-8% of thickening agent, 0.1-0.6% of defoaming agent and 0.1-0.6% of levelling agent; and the component A and the component B are compounded according to the part ratio of 1:1) to 2:1) The paint has the following beneficial effects: the paint has longer luminescence time, the fluorescent effect is enhanced and the fluorescent powder is not easy to pulverize; and in the use process, the fluorescent paint has good yellowing and weather resistances and long service life.

Owner:上海维度化工科技有限公司

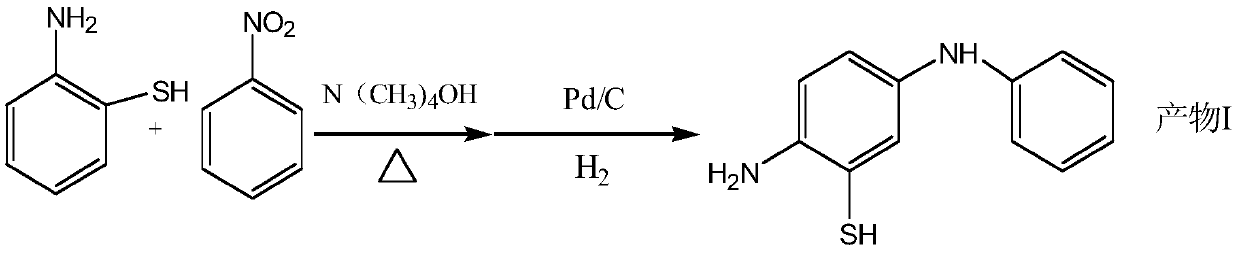

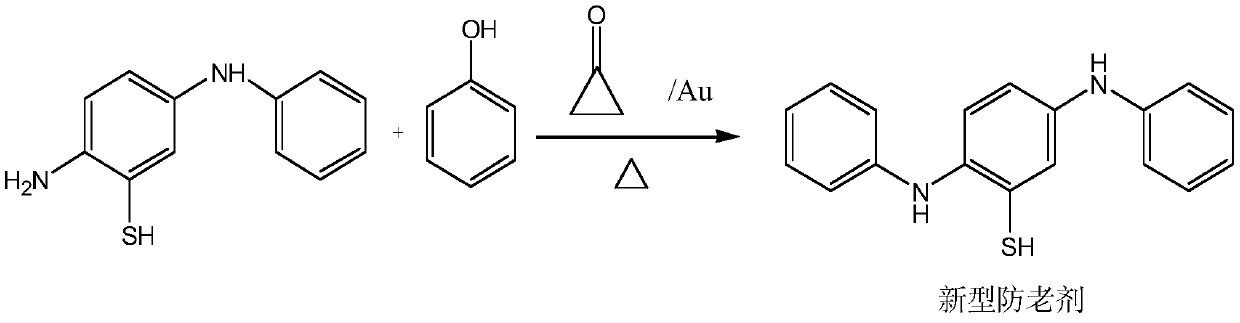

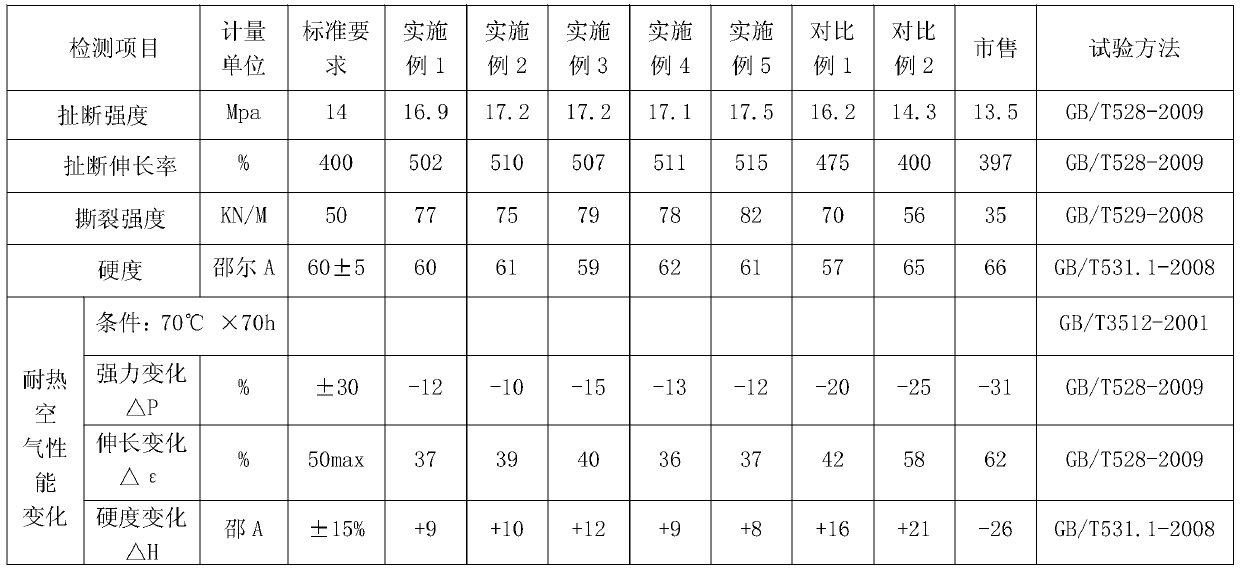

Ozone-resistant and anti-aging modified natural rubber material and preparation method thereof

The invention provides an ozone-resistant and anti-aging modified natural rubber material. The ozone-resistant and anti-aging modified natural rubber material is prepared from the following raw materials in parts by weight: 60 to 70 parts of natural rubber, 30 to 40 parts of modified butadiene rubber, 40 to 50 parts of carbon black, 2 to 2.5 parts of a vulcanizing agent, 8 to 10 parts of a softening agent, 2 to 2.5 parts of an accelerator, 3 to 3.5 parts of a common anti-aging agent, 2 to 2.5 parts of a novel anti-aging agent, 2 to 2.5 parts of an ozone-resistant protective wax, 4 to 5 parts of a dispersant and 3 to 5 parts of zinc oxide. The preparation method provided by the invention is simple and has extensively-available raw materials; and the rubber material prepared by using the preparation method provided by the invention has the advantages of good performances like aging resistance, elasticity, ultraviolet resistance, ozone resistance, oxidation resistance, wear resistance andfatigue resistance, excellent mechanical properties and broad application prospect.

Owner:南漳富元鼎航空器材配件有限公司

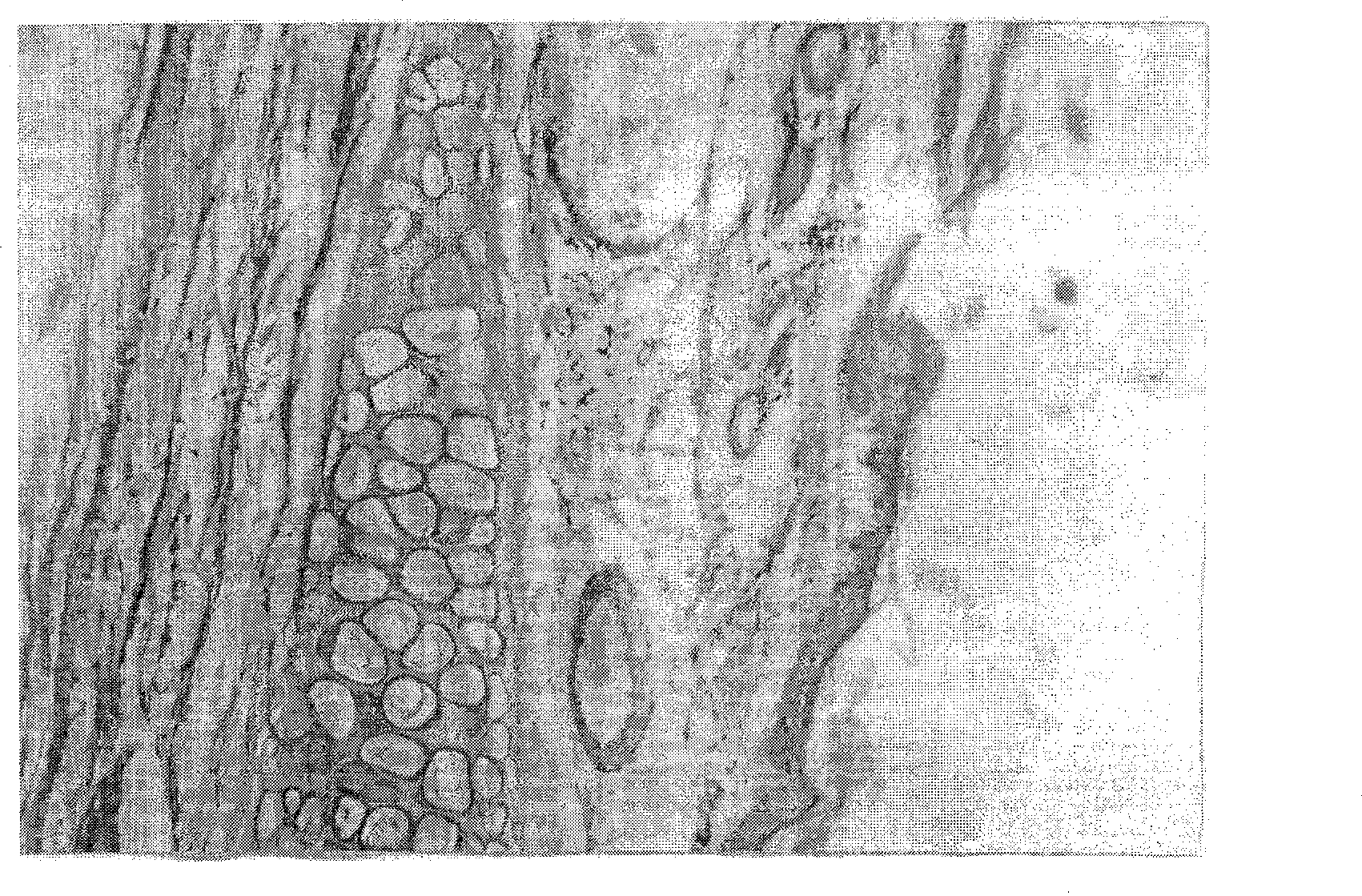

A modified carbon fiber containing ni-p-sic (titanium diboride) composite coating and its preparation and application

ActiveCN106544656BImprove oxidation resistanceEffective protectionLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a modified carbon fiber containing a Ni-P-SiC (titanium diboride) composite plating layer and a preparation method and application thereof. The modified carbon fiber consists of a carbon fiber and a Ni-P-SiC composite plating layer, a Ni-P-TiB2 composite plating layer or a Ni-P-SiC-TiB2 composite plating layer on the surface thereof. The preparation method comprises the following steps: the surface of the carbon fiber is put in chemical plating liquid for chemically plating the Ni-P-SiC, Ni-P-TiB2 or Ni-P-SiC-TiB2 composite layer to obtain the compact and uniform composite plating layer after pretreatment of degumming, roughening, neutralization, sensitization, activation, reduction and peptization; the bonding force of the composite plating layer and the carbon fiber is high; the compatibility of the modified carbon fiber and a metal matrix is excellent; the dispersibility in the metal matrix is excellent; a carbon fiber reinforced metal base composite material with good mechanical performance, stable performance and good reliability can be prepared; and the preparation method of the modified carbon fiber is simple and low in cost, and facilitates industrial production.

Owner:CENT SOUTH UNIV

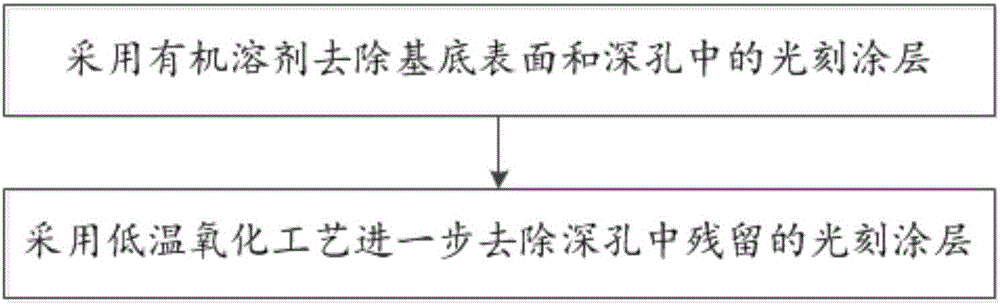

Removal method for photoetching coating on carbon-containing porous material substrate

ActiveCN105843001AOvercome speedOvercome the shortcomings of weak abilityPhotosensitive material processingOrganic solventElectrical performance

The invention relates to a removal method for a photoetching coating on a carbon-containing porous material substrate. In the invention, organic solvent removal and low-temperature oxidizing removal are combined, wherein the photoetching coating, which is easy to dissolve in the organic solvent, on the surface and in deep pores of the substrate is removed firstly by an organic solvent, and then the residual photoetching coating in the deep pores is removed through the low-temperature oxidizing process. The method effectively overcomes the defects of incomplete removal with the organic solvent and low removal speed and low capability of the low-temperature oxidizing process, increases removal capability on the photoetching coating, can completely remove the photoetching coating, and ensures structural performance and electrical performance of porous structures in the carbon-containing porous material substrate, thereby providing convenience for subsequent processes.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Method and system for reducing oxidation speed of electrode of flow battery

ActiveCN110729504AIncrease concentrationReduce oxidation rateRegenerative fuel cellsElectrolytic agentCarbon felt

The invention discloses a method and system for reducing the oxidation speed of the electrode of a flow battery and belongs to the field of flow batteries and aims to solve the problem of the oxidation of the electrode of the flow battery. The method is characterized in that the method comprises a step of adding an organic reducing agent into a positive electrolyte solution. With the method and system of the invention adopted, the oxidation speed of a positive carbon felt electrode can be reduced.

Owner:DALIAN RONGKE POWER

Grid section used for sintering acid mine

The invention relates to a grid section used for sintering acid mine. The grid section comprises the following components in percentage by weight: 1.1-1.3% of C, 26.0-28.0% of Cr, 0.3-0.5% of Mo, 1.0-1.5% of Ni, 1.0-1.5% of Si, 0.5-1.0% of Mn, 0.10% of Ti, 0.05-0.15% of Re, 1.0-2.0% of Al and the balance of Fe. The grid section disclosed by the invention is totally suitable for acid mine sintering working conditions and satisfies use requirements, the service life of the grid section is prolonged to more than 12 months from less than 3 months, and therefore the use cost of the grid section is greatly lowered. Meanwhile, replacement frequency of the grid section can be reduced, the labor intensity of operators is lowered, downtime for replacing the grid section is shortened, and production efficiency is improved.

Owner:JINAN JIGANG IRON ALLOY FACTORY

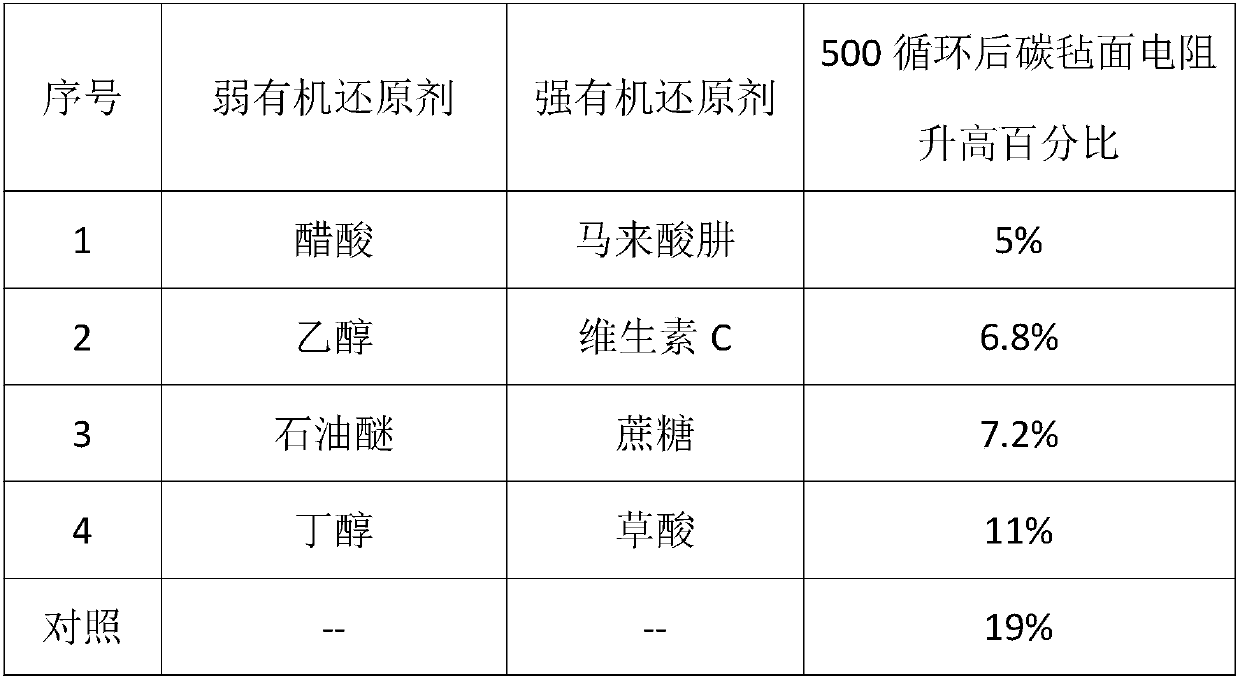

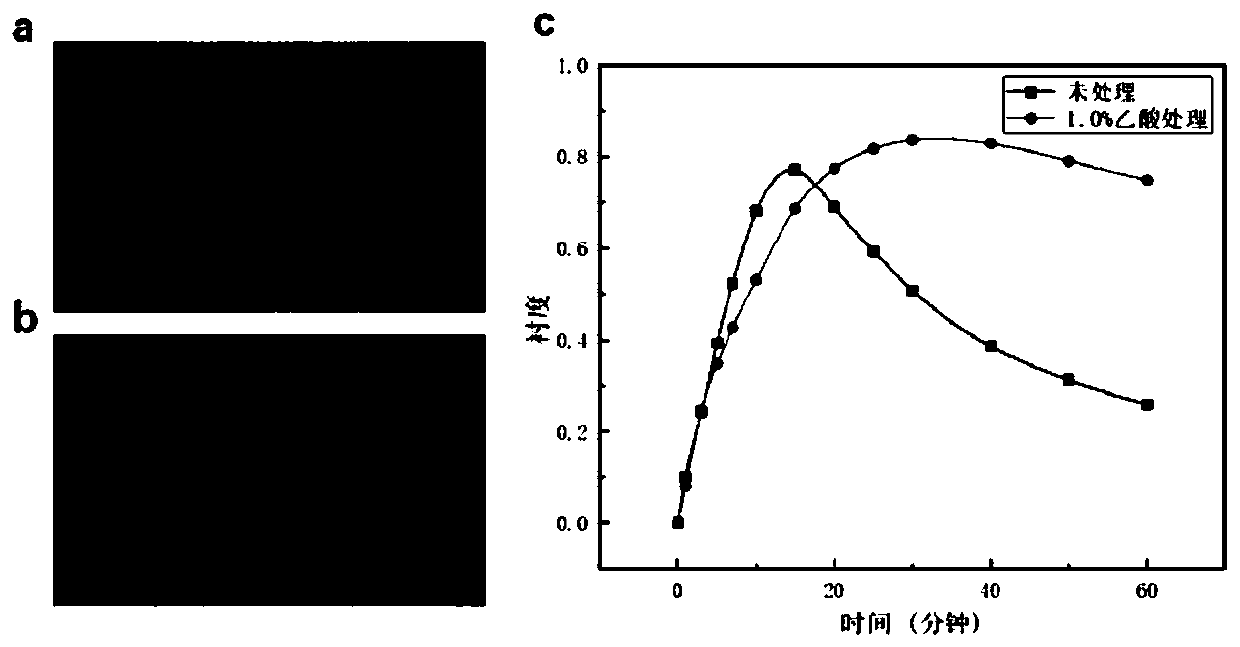

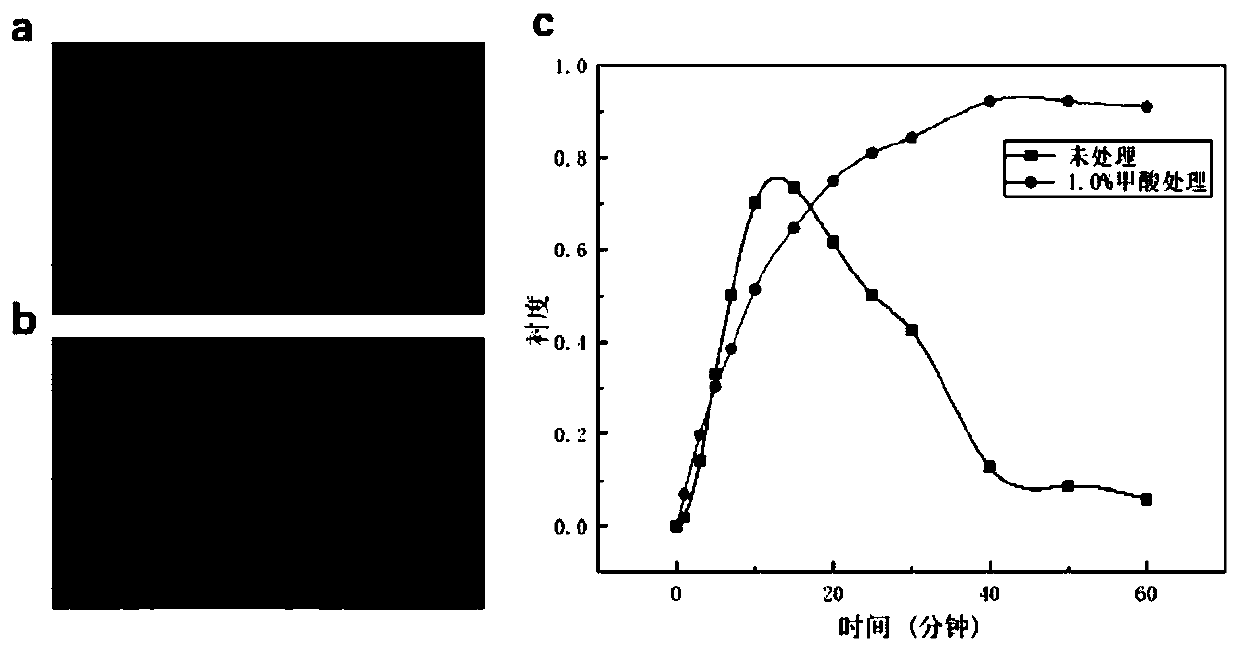

Method for reducing oxidation speed of metal product

ActiveCN111155160AReduce oxidation rateSlow oxidationAnodisationSolid state diffusion coatingElectrolytic agentAqueous solution

The invention provides a method for reducing the oxidation speed of a metal product. The method comprises the following steps of: constructing an electrolytic cell by taking a metal sample to be treated as an anode and taking an aqueous solution containing weak acid as an electrolyte; after electrifying for a period of time, powering off and taking out the sample; and (3) cleaning and drying the sample to obtain the metal product. According to the method, the oxidation speed of the metal product can be reduced through quite simple operation, and the surface property of the metal product can bemaintained.

Owner:PEKING UNIV

Crystalline silicon solar cell diffusion dead layer removing method

InactiveCN103996750AUniform removalUniform junction depthFinal product manufactureSemiconductor/solid-state device manufacturingSurface oxidationAqueous solution

The invention provides a crystalline silicon solar cell diffusion dead layer removing method. The method includes the steps of oxidizing a dead layer through a NaClO water solution or a NaBrO4 water solution or an H2O2 alkali solution for a crystal silicon wafer where phosphorosilicate glass is removed, and removing a surface oxidized layer through an HF water solution. By means of the crystalline silicon solar cell diffusion dead layer removing method, it can be ensured that the dead layer can be thoroughly removed, the junction depth is more uniform, and the open-circuit voltage and short-circuit current are increased.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

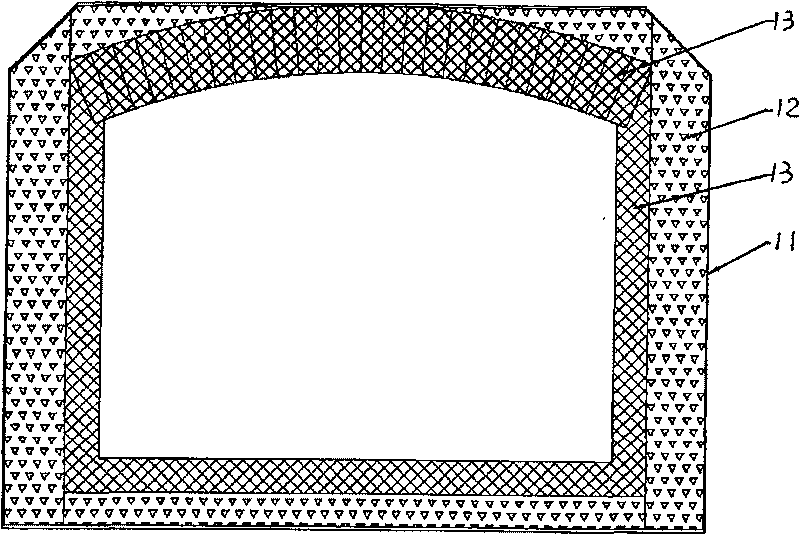

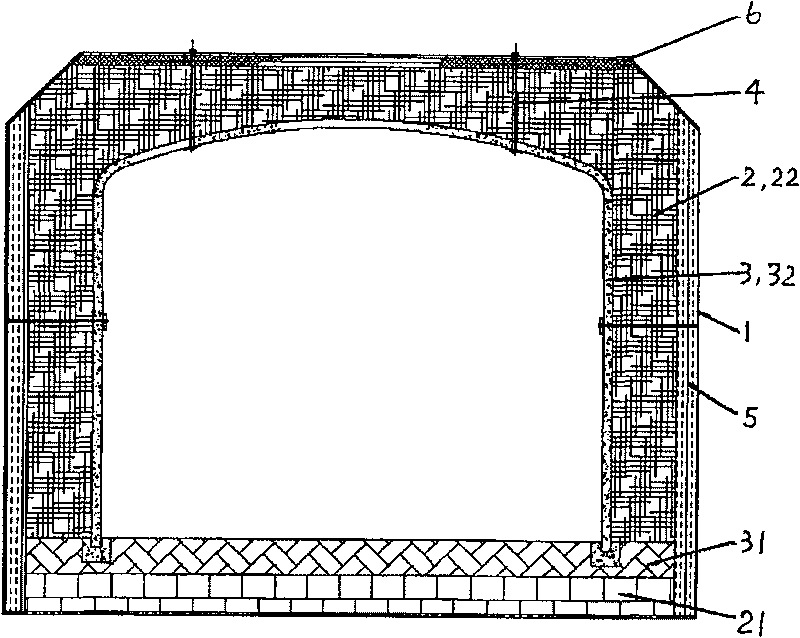

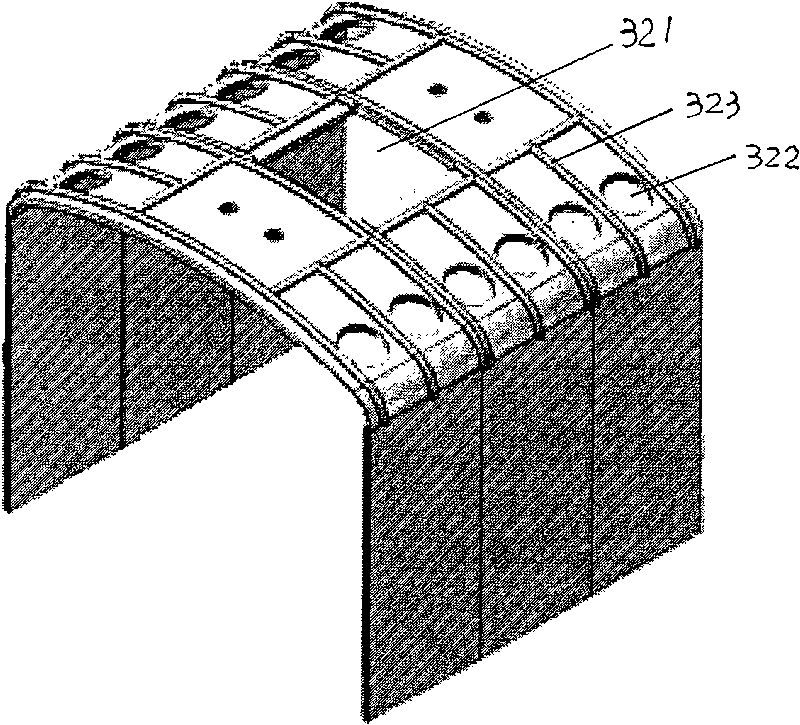

Industrial furnace liner

Owner:SHANGHAI HUISEN MTH INDAL FURNACES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com