Method for reducing oxidation speed of metal product

A metal product, oxidation speed technology, applied in anodic oxidation, metal material coating process, solid-state diffusion coating, etc., can solve the problems of complicated process, high price, copper damage, etc., and achieve the effect of simple operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

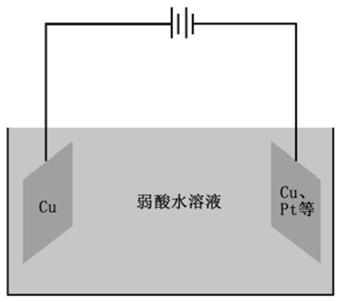

[0030] Example one: such as figure 1 Shown is a schematic diagram of an electrolytic cell used in the present invention. The electrolytic cell includes an anode, a cathode and an electrolyte, wherein the metal sample to be processed is used as the anode, and the weak acid-containing solution is used as the electrolyte. The cathode includes copper or platinum. In a specific embodiment, the cathode includes copper foil.

[0031] The present invention provides a method for reducing the oxidation rate of metal products by electrochemical treatment, which includes the following steps:

[0032] (1) Prepare the metal sample to be processed;

[0033] (2) Use the metal sample to be processed as the anode and the weak acid solution as the electrolyte to build an electrolytic cell;

[0034] (Three), the current density is 0.001-0.01A / cm 2 Power on for 5-60 minutes;

[0035] (4) Take out the sample after the power is cut off, and quickly wipe dry after cleaning to obtain the metal product.

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com