A modified carbon fiber containing ni-p-sic (titanium diboride) composite coating and its preparation and application

A composite coating, ni-p-sic technology, applied in liquid chemical plating, coating, metal material coating process and other directions, can solve the problems of poor wettability and dispersion, short service life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Step 1: Carbon fiber pretreatment

[0061] (1) Degumming: Put the carbon fiber into a muffle furnace and heat it at 400°C for 1 hour. After degumming, soak in absolute ethanol for 5 minutes to remove oil, and then wash with deionized water.

[0062] (2) Roughening: Treat with potassium dichromate (20g / L) and sulfuric acid (100mL / L) at room temperature for 10 minutes. The degummed carbon fiber has fewer active functional groups on the surface, and coarsening can change the state of the functional group and increase the specific surface area of the carbon fiber. Take out the roughened carbon fiber, and then wash the acidified carbon fiber with distilled water under the assistance of ultrasonic waves until the washed liquid is neutral.

[0063] (3) Neutralization: Use sodium hydroxide to neutralize the acid remaining in the roughening process.

[0064] (4) Sensitization: For sensitization, treat with stannous chloride (14g / L) and hydrochloric acid (40mL / L) at room tem...

Embodiment 2

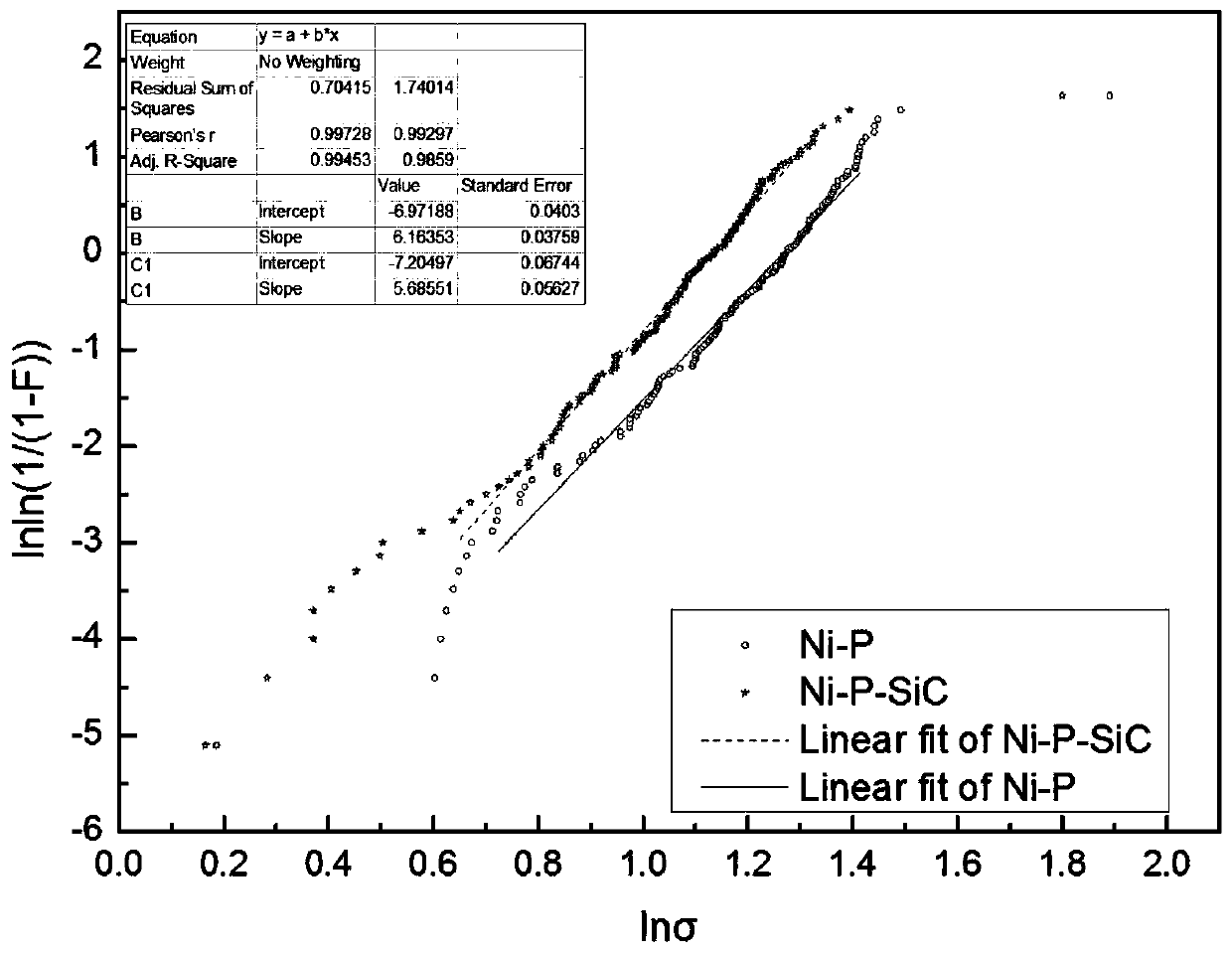

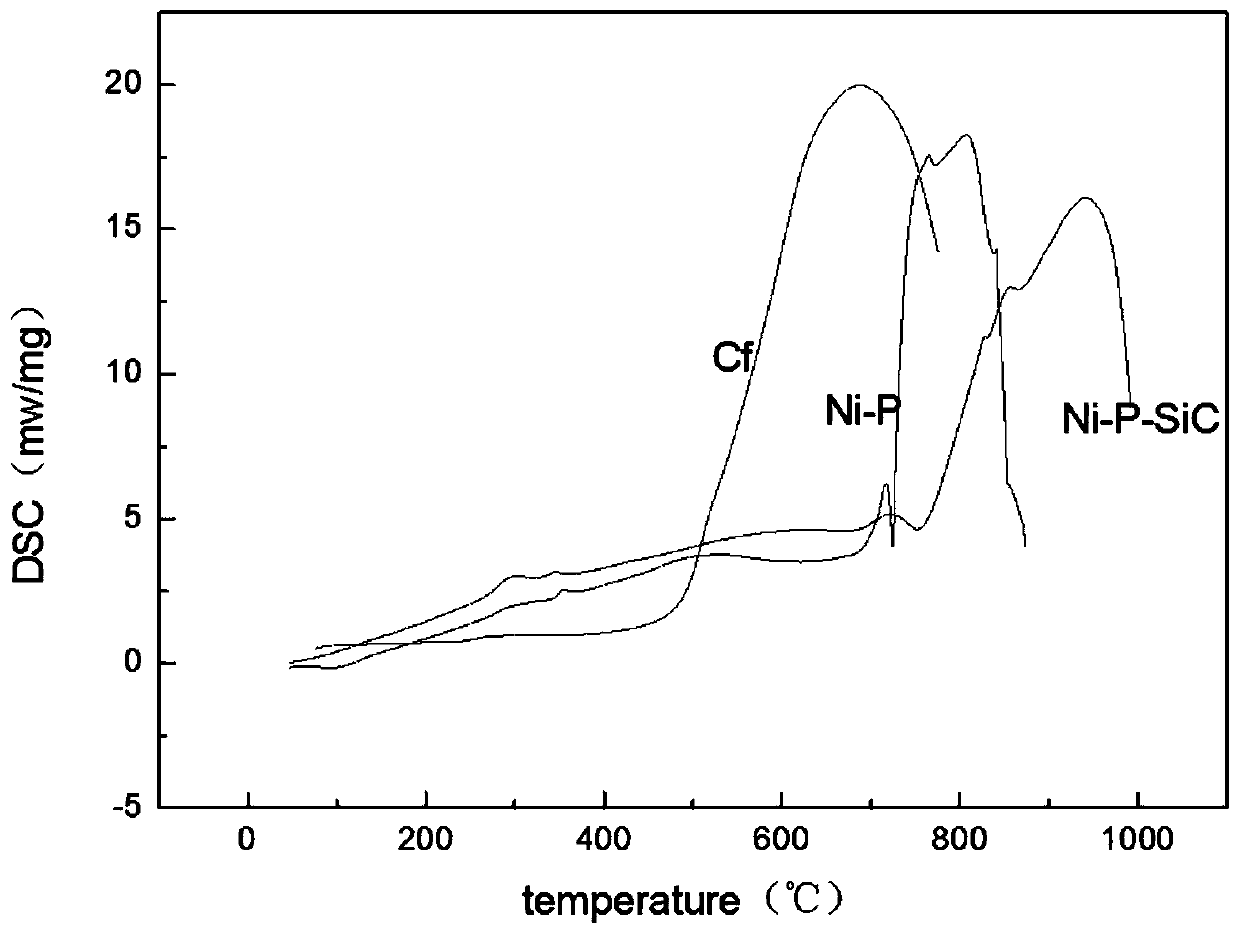

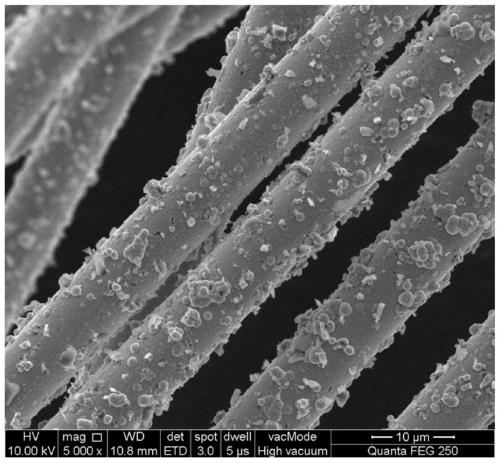

[0072] The surface and cross-sectional morphology of the carbon fiber Ni-P-nano-SiC composite coating are as attached image 3 and Figure 4 shown.

[0073] Step 1: Carbon fiber pretreatment

[0074] (1) Degumming: Put the carbon fiber into a muffle furnace and heat it at 430°C for 0.8h. After degumming, soak in absolute ethanol for 5 minutes to remove oil, and then wash with deionized water.

[0075] (2) Roughening: Treat with potassium dichromate (24g / L) and sulfuric acid (100mL / L) at room temperature for 10 minutes. The degummed carbon fiber has fewer active functional groups on the surface, and coarsening can change the state of the functional group and increase the specific surface area of the carbon fiber. Take out the roughened carbon fiber, and then wash the acidified carbon fiber with distilled water under the assistance of ultrasonic waves until the washed liquid is neutral.

[0076] (3) Neutralization: Use sodium hydroxide to neutralize the acid remaining in ...

Embodiment 3

[0085] Step 1: Carbon fiber pretreatment

[0086] (1) Degumming: Put the carbon fiber into a muffle furnace and heat it at 400°C for 1 hour. After degumming, soak in absolute ethanol for 5 minutes to remove oil, and then wash with deionized water.

[0087] (2) Roughening: Treat with potassium dichromate (20g / L) and sulfuric acid (100mL / L) at room temperature for 10 minutes. The degummed carbon fiber has fewer active functional groups on the surface, and coarsening can change the state of the functional group and increase the specific surface area of the carbon fiber. Take out the roughened carbon fiber, and then wash the acidified carbon fiber with distilled water under the assistance of ultrasonic waves until the washed liquid is neutral.

[0088] (3) Neutralization: Use sodium hydroxide to neutralize the acid remaining in the roughening process.

[0089] (4) Sensitization: For sensitization, treat with stannous chloride (14g / L) and hydrochloric acid (40mL / L) at room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com