Low-peroxide-value and high-fat fish ball added with seaweed concentrate and preparation method of fish ball

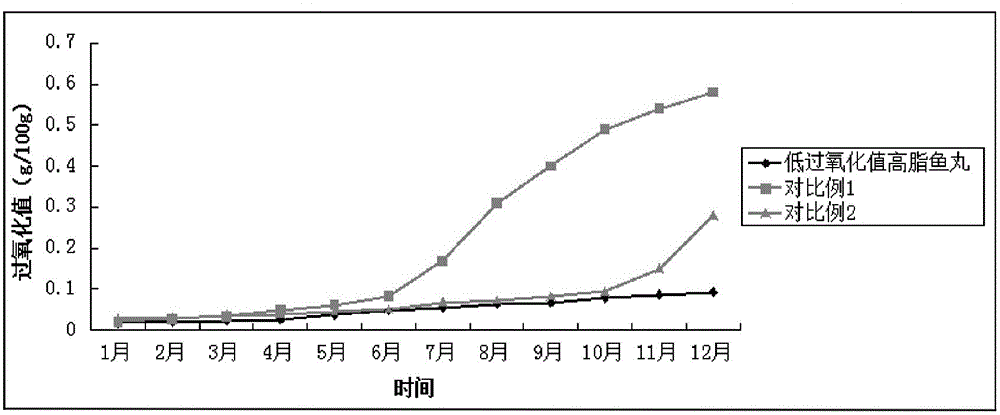

A technology of seaweed concentrate and peroxide value, which is applied in food preparation, food ingredients as antioxidants, food science, etc., can solve the problems of destroying product flavor and texture, low addition amount, short shelf life, etc., and achieve the purpose of inhibiting fat Strong lipid oxidation ability, inhibition of lipid peroxidation, and slow lipid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing high-fat fish balls with low peroxide value added with seaweed concentrate, the steps comprising:

[0028] Step 1: Preparation of the skin, using chopping process, thawing surimi, slicing, chopping until fine particles, adding compound phosphate for crushing, until the slurry is viscous, then adding salt for chopping, chopping until pulp shape, no hard particles, add soy protein isolate, egg white, chop and mix well, add jelly, oil and seaweed concentrate mixture, after mixing, add monosodium glutamate, sucrose, starch, mix well, chop and mix, add ice Water, control the slurry temperature, the final slurry temperature does not exceed 10°C;

[0029] Step 2: Preparation of stuffing, thawing frozen pork, slicing and twisting, adding compound phosphate, crushing until there are no hard particles, adding salt and stirring, stirring until the meat paste is more viscous, adding jelly, oil and The mixture of seaweed concentrate, finally add sucrose, mono...

Embodiment 1

[0035] Seaweed concentrate is pre-mixed with oil and jelly, stir well, and add as a mixture.

[0036] Skin composition in parts by weight: 70 parts of frozen surimi, 0.1 part of compound phosphate, 1.5 parts of table salt, 3 parts of soybean protein isolate, 2 parts of egg white, 1 part of jelly, 3 parts of oil, 2 parts of seaweed concentrate, 0.2 part of monosodium glutamate , 0.3 parts of sucrose, 10 parts of starch, and 10 parts of ice water.

[0037] The stuffing consists of 12 parts by weight of frozen pork, 0.05 part of compound phosphate, 1 part of salt, 5 parts of jelly, 12 parts of oil, 3 parts of seaweed concentrate, 0.2 part of sucrose, 0.1 part of monosodium glutamate, and 0.2 part of seasoning.

[0038] Process flow:

[0039] (1) Using chopping process, 70 parts of surimi are defrosted properly, sliced, chopped into fine particles, added 0.1 parts of compound phosphate for crushing, until the slurry is viscous, then added 1.5 parts of salt for chopping, chopped ...

Embodiment 5

[0053] Embodiment five reduces the addition of fat, other formula and operation are the same as embodiment one, what make is low-fat fish ball, because the addition of fat is not much, after testing, its peroxide value is 0.012g / 100g, frozen storage 12 After one month, the peroxide value was 0.032g / 100g; the low-fat fish balls made by replacing the seaweed concentrate in the above formula with water had an initial peroxide value of 0.013g / 100g, and after 12 months of freezing, the peroxide value It is 0.095g / 100g, and the comparison shows that the scheme provided by the invention is also suitable for low-fat fish balls, which can delay the rise of peroxide value and prolong the shelf life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com