Low-loss metallized film

A metallized thin film, low loss technology, applied in the field of capacitors, can solve the problems affecting the performance and life of the metallized thin film, the loss of the metal coating, the difficulty of heat dissipation, etc., to solve the problem of breakdown due to heat dissipation and high oxidation resistance Ability to avoid air oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

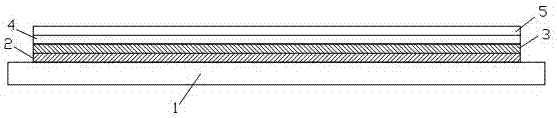

[0014] Such as figure 1 As shown, a low-loss metallized film provided by the present invention includes a dielectric base film 1 on which a silver-zinc-aluminum composite metal layer 2 is arranged, and the silver-zinc-aluminum composite metal layer 2 is provided with an aluminum-coated layer 3, the surface of the aluminum-coated layer 3 is provided with a carbon nanotube layer 4, and the surface 4 of the carbon nanotube layer is provided with a sealing oil protection layer 5.

[0015] The silver-zinc-aluminum composite metal layer 2, due to the introduction of silver, improves the sensitization effect of the dielectric base film, enhances the adhesion between the coating and the dielectric base film, and achieves breakthroughs in performance and oxidation resistance.

[0016] Carbon nanotubes are the most ideal functional fillers for heat-dissipating coatings. They are known as the blackest substance in the world. The emissivity coefficient is close to 1. It is also one of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com