Thioether oxidation tower for producing dimethyl sulfoxide

A technology of dimethyl sulfoxide and oxidation tower, which is applied in the field of reaction towers, can solve problems such as high nitric oxide content, high oxidation temperature, and gas phase reaction, and achieve low nitric oxide content, low oxidation temperature, and good safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

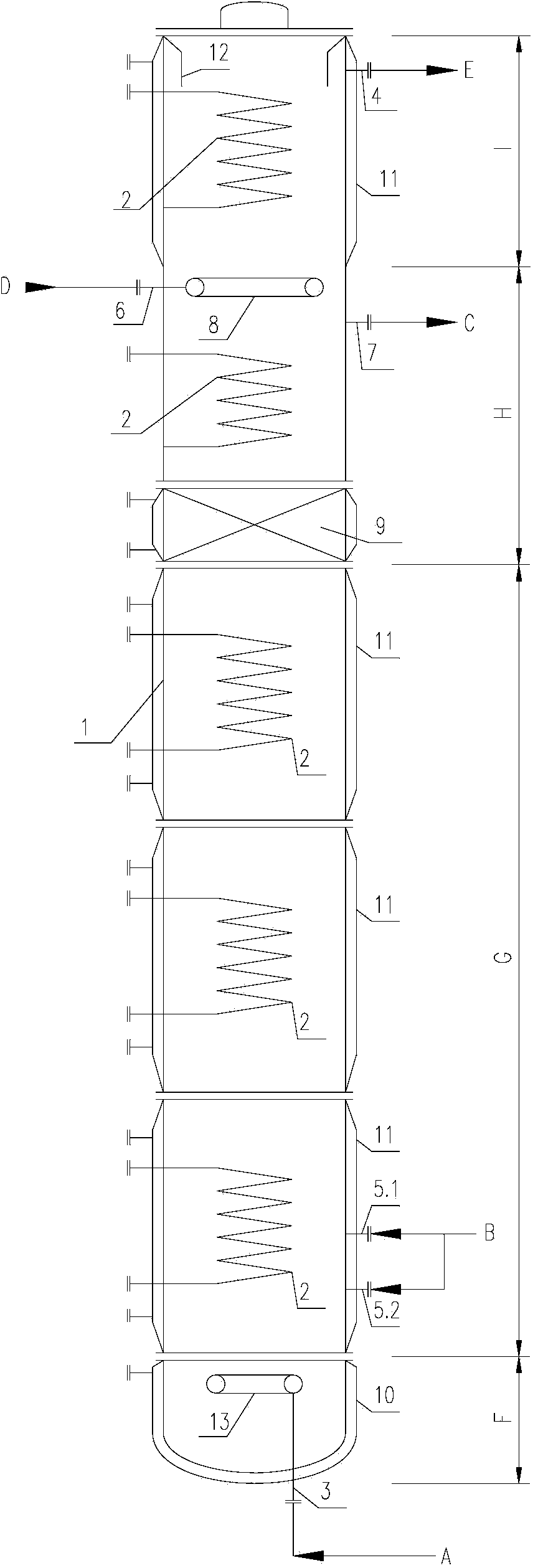

[0022] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0023] see figure 1 , the tower body consists of heating zone F, reaction zone G, sub-cooling zone H and cooling zone I from bottom to top. Cooling water coils are arranged in the reaction zone G, sub-cooling zone H and cooling zone I, and the tower A cooling water jacket 11 is provided on the wall, and an oxidizing gas distributor 13 and a hot water jacket 10 on the tower wall are provided in the heating zone.

[0024] The heating zone F is provided with an oxidizing gas inlet 3 connected to an oxidizing gas gas distributor 13, and the lower section of the reaction zone G has an upper sulfide feed layer 5.1 and a lower sulfide feed layer 5.2 with different vertical heights. The vertical distance between the lower sulfide feed layer 5.2 and the top surface of the heating zone F is 150mm-300mm, and the vertical height difference between the upper sulfide feed layer 5.1 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com