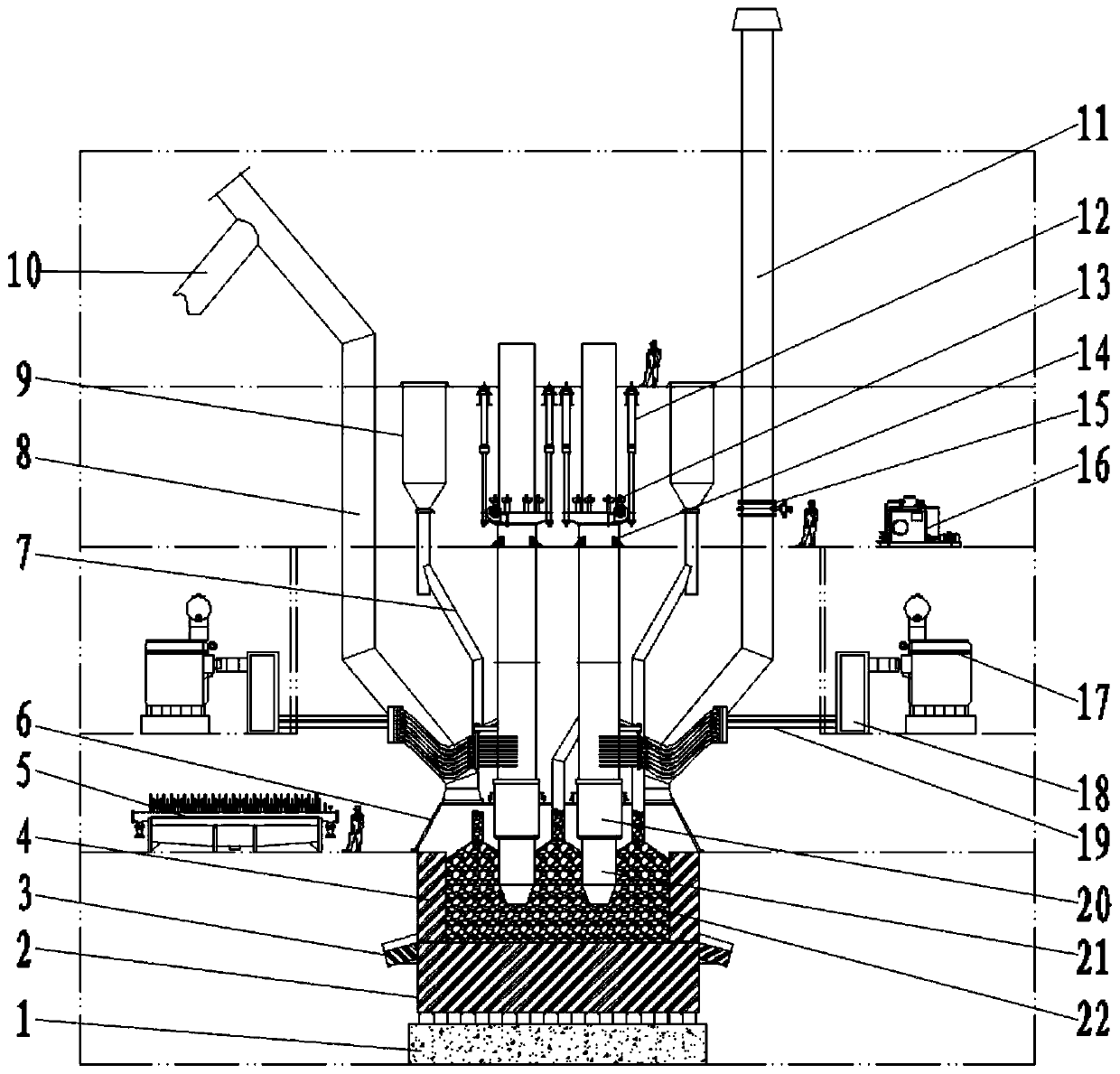

Closed non-fixed anode direct-current submerged arc furnace

A submerged arc furnace without fixed technology, which is applied in furnace, electric furnace heating, waste heat treatment, etc., can solve the problems of low element recovery rate, unstable operation, high comprehensive energy consumption, etc., and achieve high element recovery rate, reliable equipment operation, The effect of high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0051] The raw materials prepared according to a certain ratio can be added to the furnace top silo 9 through belt conveyors, tank trucks, feeders, hoisting, etc., and then added to the furnace through the feeding pipe 7, and the continuous feeding method is adopted. The inside of the blanking pipe 7 is always full of raw materials. As the product comes out of the furnace or the furnace charge 22 melts, the material level in the furnace drops, and the raw materials in the furnace top bunker 9 are automatically replenished into the furnace through the blanking pipe 7 by gravity. Raw materials are naturally piled up in the furnace, and there is no need to control the feeding amount and handle the material surface. The quantity and position of the furnace top bunker 9 and the feeding pipe 7 can be reasonably matched and arranged according to the size of the furnace type and the specific smelting process.

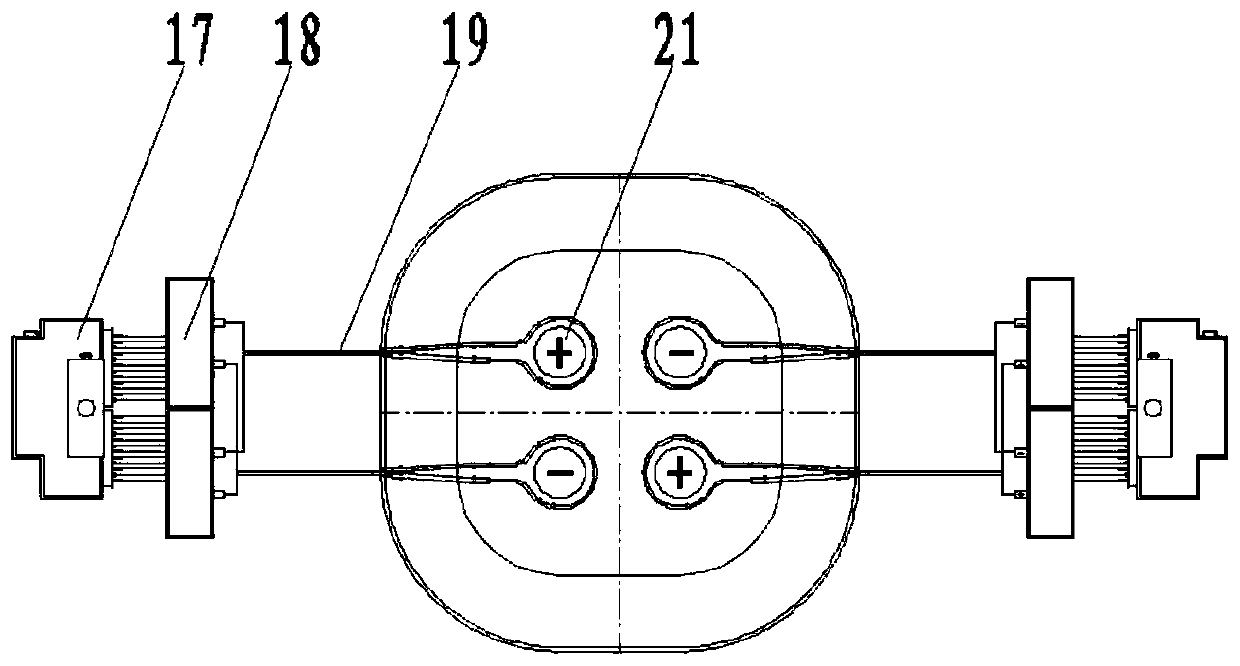

[0052] The primary side of the transformer 17 inputs alternating current, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com