Ozone-resistant and anti-aging modified natural rubber material and preparation method thereof

A natural rubber and ozone-resistant technology, applied in the field of rubber materials, can solve the problems of poor ozone oxidation resistance, poor oxidation resistance, and short service life, and achieve the effects of slow migration speed, low volatility, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

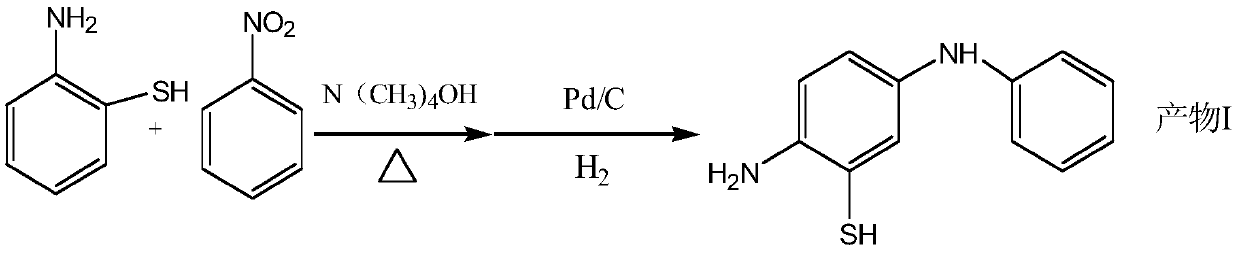

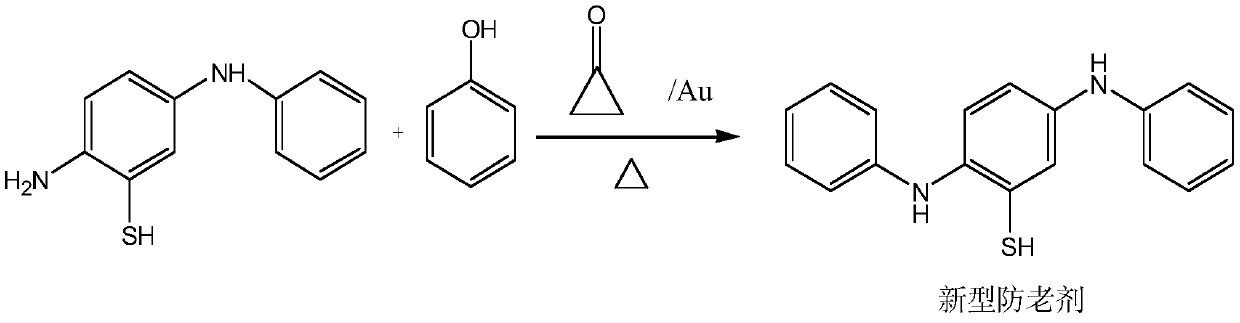

Method used

Image

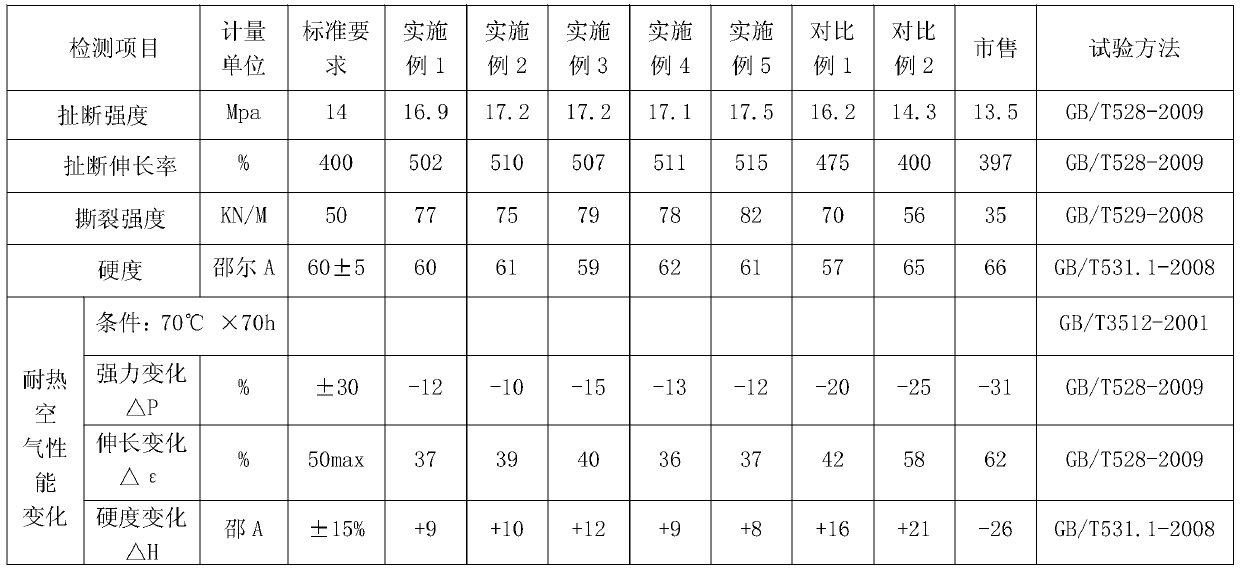

Examples

Embodiment 1

[0033] Composition of raw materials (parts by weight): 60 parts of natural rubber, 30 parts of modified butadiene rubber, 40 parts of carbon black, 2 parts of vulcanizing agent, 8 parts of naphthenic oil, 1 part of accelerator MBTS-751, 1 part of accelerator M-80, 3 parts of commonly used anti-aging agent, 2 parts of new anti-aging agent, 2 parts of anti-ozone protective wax, 4 parts of dispersant and 3 parts of zinc oxide. :4.

[0034] Among them, the modified butadiene rubber is prepared by the following method: add the silane coupling agent KH500 into the water-ethanol solution (volume ratio 1:1), hydrolyze it under acidic conditions for 0.5h, then add 1g carbon fiber, 2g nanometer two Silica and 1g of kaolin were stirred and reacted for 1 hour, filtered under reduced pressure, washed with deionized water to obtain 4.5g of modifier; 20g of butadiene rubber was masticated with an open mill, and 4.5g of modifier was added for mixing to obtain The mixed rubber was parked for ...

Embodiment 2

[0043] Raw material composition (parts by weight): 70 parts of natural rubber, 40 parts of modified butadiene rubber, 50 parts of carbon black, 2.5 parts of sulfur, 10 parts of engine oil, 0.5 parts of accelerator M, 1 part of accelerator DM, and 1 part of accelerator DPG , 3.5 parts of commonly used anti-aging agent, 2.5 parts of new anti-aging agent, 2.5 parts of anti-ozone protective wax, 5 parts of dispersant and 5 parts of zinc oxide; 1:4.

[0044] Among them, the modified butadiene rubber is prepared by the following method: add the silane coupling agent KH500 into the water-ethanol solution (volume ratio 1:1), hydrolyze it under acidic conditions for 0.5h, then add 1g carbon fiber, 2g nanometer two Silica and 1g of kaolin were stirred and reacted for 1 hour, filtered under reduced pressure, washed with deionized water to obtain 4.5g of modifier; 20g of butadiene rubber was masticated with an open mill, and 4.5g of modifier was added for mixing to obtain The mixed rubbe...

Embodiment 3

[0049] Raw material composition (parts by weight): 62 parts of natural rubber, 32 parts of modified butadiene rubber, 42 parts of carbon black, 2.1 parts of sulfur, 8.5 parts of softener, 2.1 parts of accelerator DM / DPG, 3.1 parts of commonly used anti-aging agent, new anti-aging 2.1 parts of agent, 2.1 parts of anti-ozone protective wax, 4.2 parts of dispersant and 3.2 parts of zinc oxide; carbon black is made by mixing wear-resistant carbon black and fast extrusion carbon black, and the mass ratio is 1:4.

[0050] Among them, the modified butadiene rubber is prepared by the following method: add the silane coupling agent KH500 into the water-ethanol solution (volume ratio 1:1), hydrolyze it under acidic conditions for 0.5h, then add 1g carbon fiber, 2g nanometer two Silica and 1g of kaolin were stirred and reacted for 1 hour, filtered under reduced pressure, washed with deionized water to obtain 4.5g of modifier; 20g of butadiene rubber was masticated with an open mill, and 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com