Fully-automatic production equipment for egg products

A technology for production equipment and egg products, applied in the field of automatic egg product production equipment, can solve the problems of poor stability, inability to achieve, no technical solutions, etc., and achieve the effects of good stability, easy action control, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

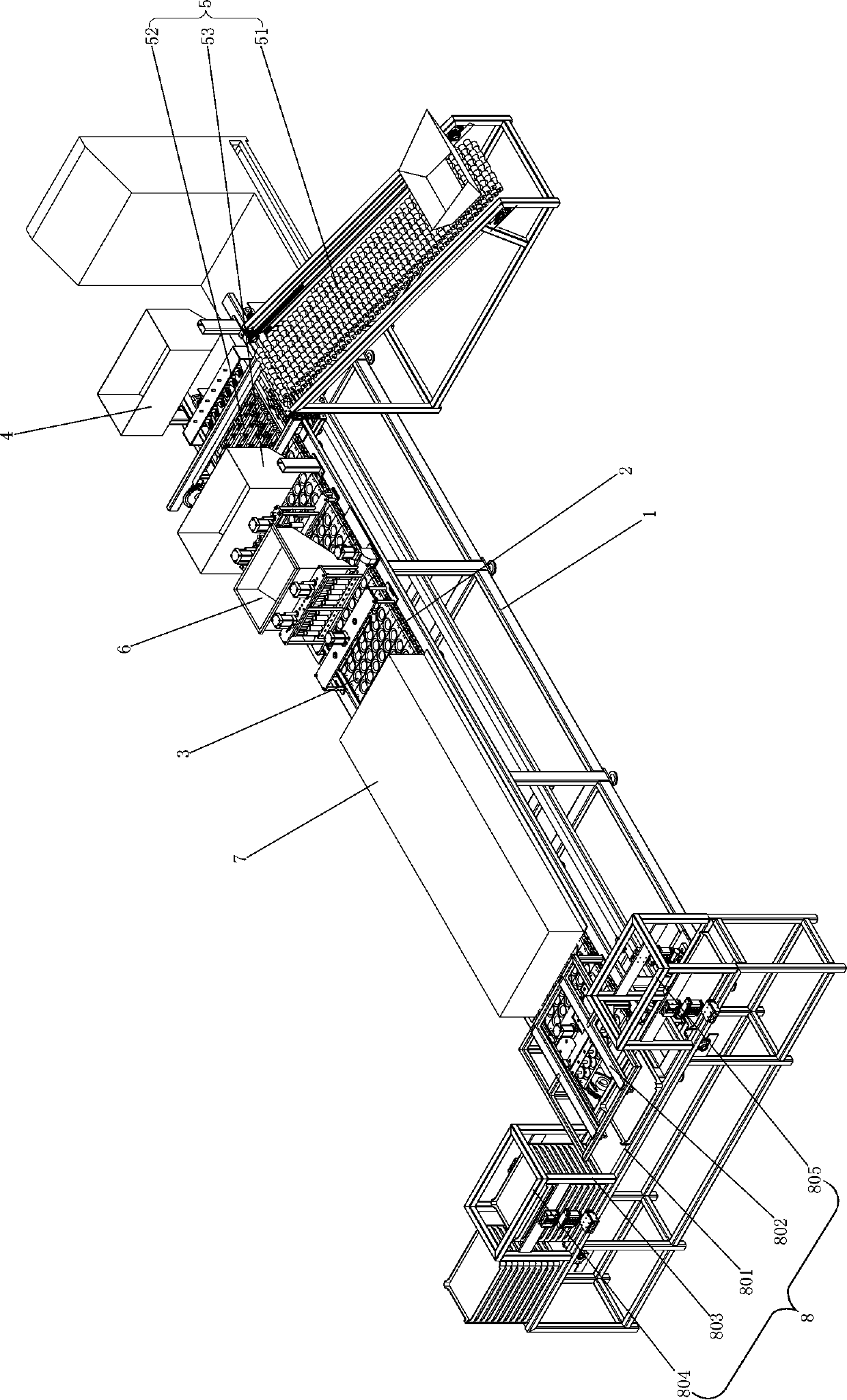

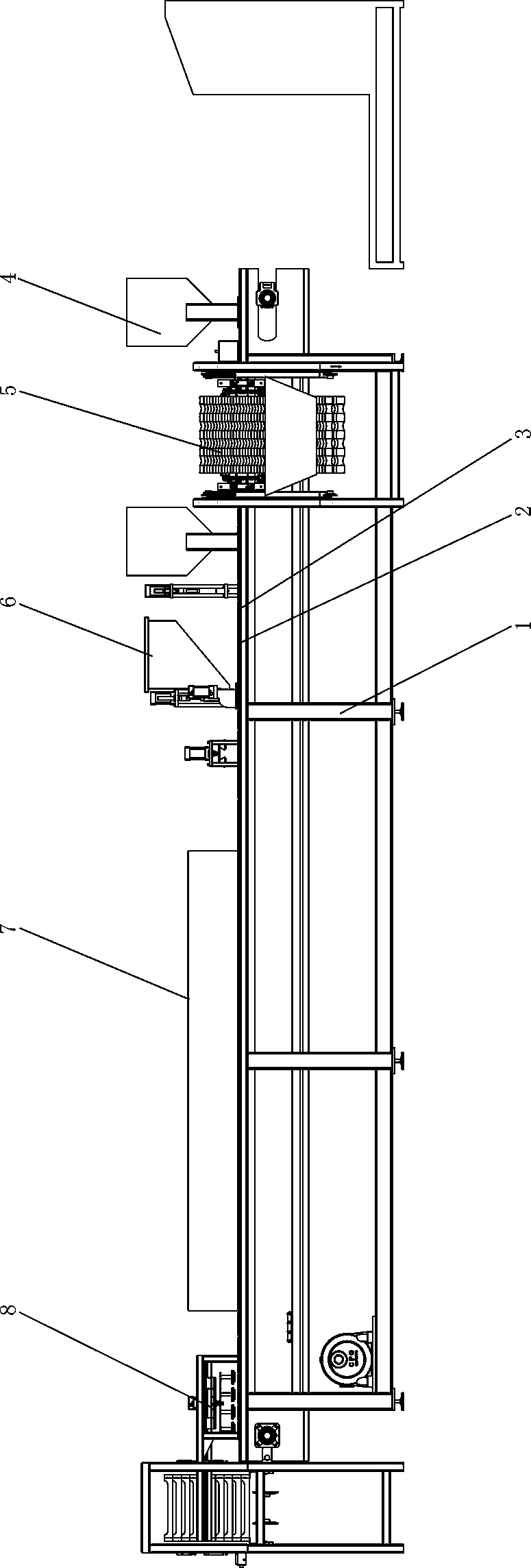

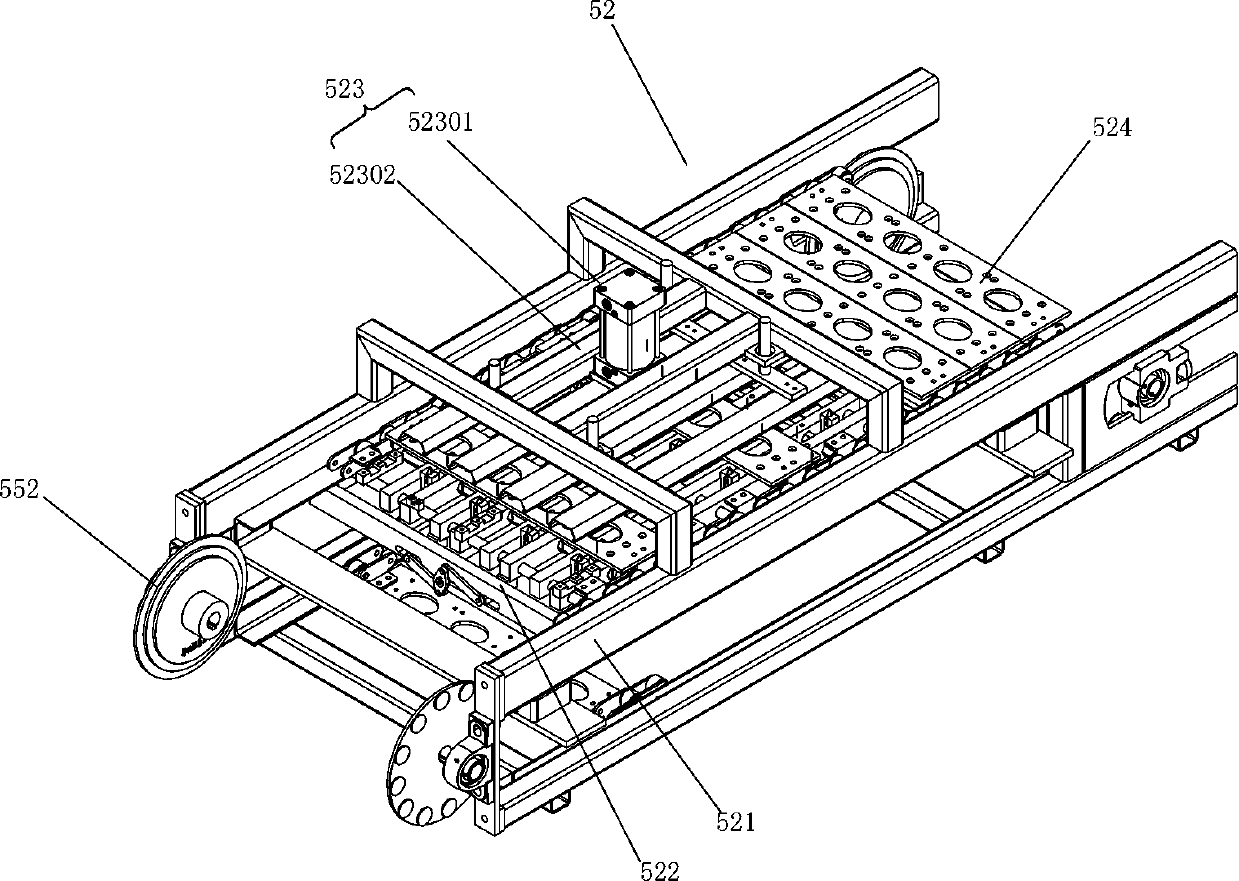

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, this fully automatic egg product production equipment includes a frame 1, a circular conveying mechanism 2, a plurality of product templates 3, an oil brushing device 4, an egg liquid adding device 5, a meat sauce pouring device 6, a drying device 7 and a finished product The collection device 8, the circulating conveying mechanism 2 are installed on the frame 1, each product template 3 is installed on the circulating conveying mechanism 2, the oil brushing device 4, the egg liquid adding device 5, the meat sauce pouring device 6, the drying device 7, the finished product Collecting device 8 is installed on the frame 1 successively along the conveying direction of circulation conveying mechanism 2; Egg liquid adding device 5 comprises egg feeding mechanism 51, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com