Roller brush self-cleaning device of sweeper

A self-cleaning and sweeping technology, applied in the field of cleaning, can solve problems such as affecting the cleaning area of the roller brush, and achieve the effect of stable cleaning degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

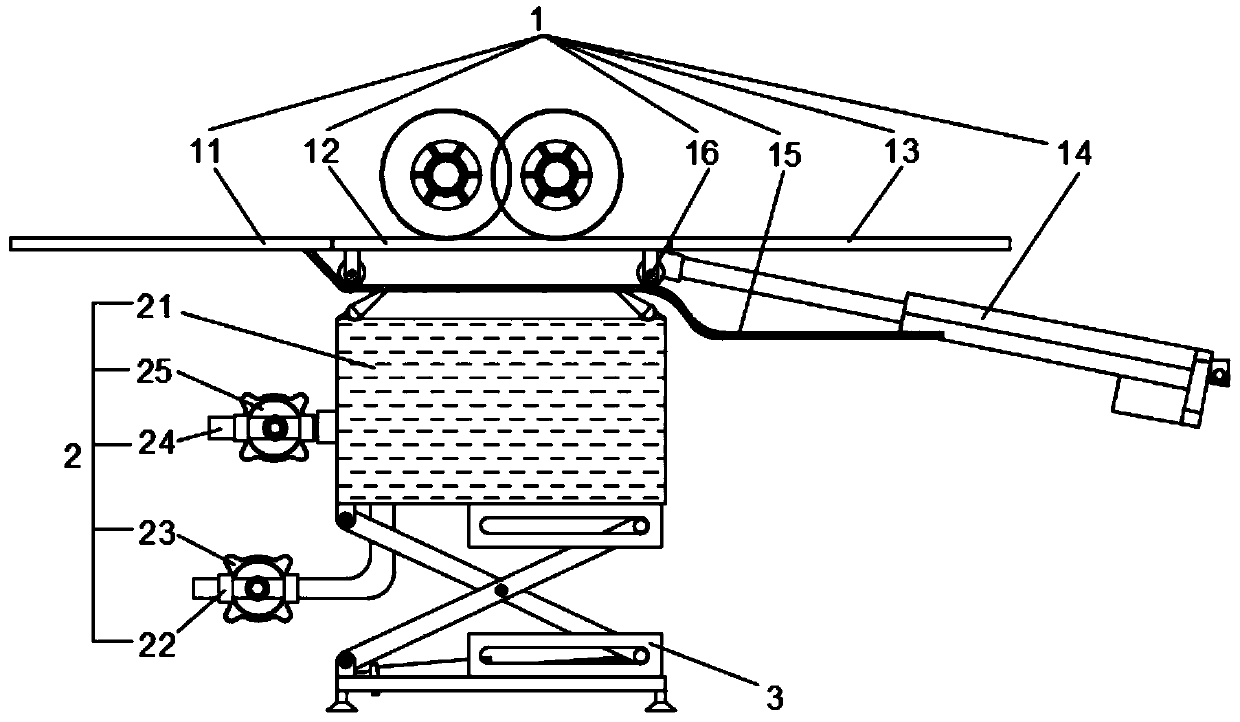

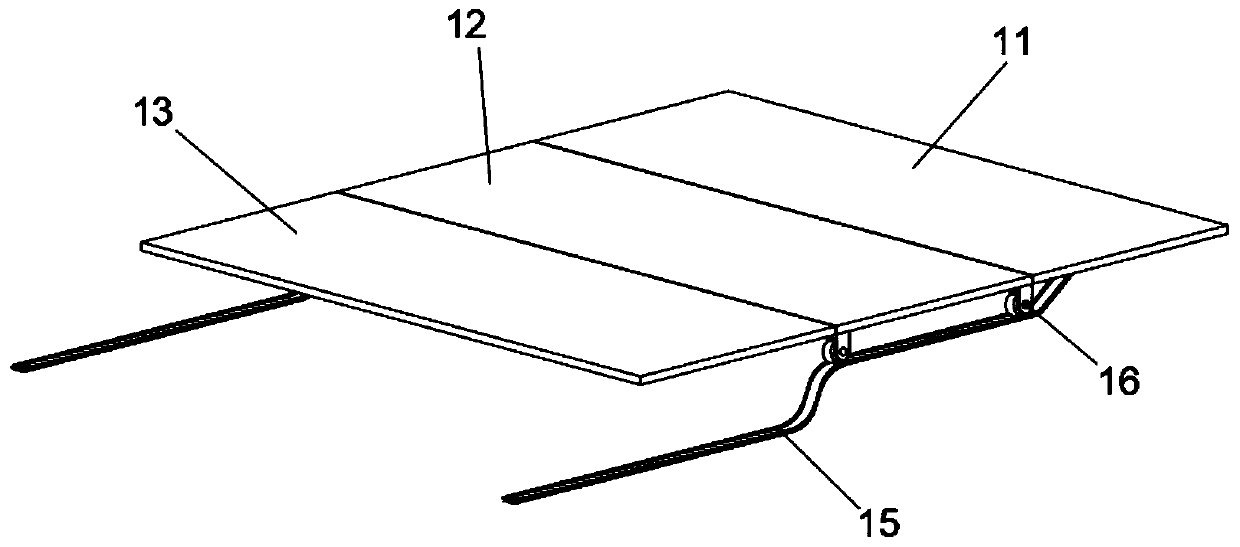

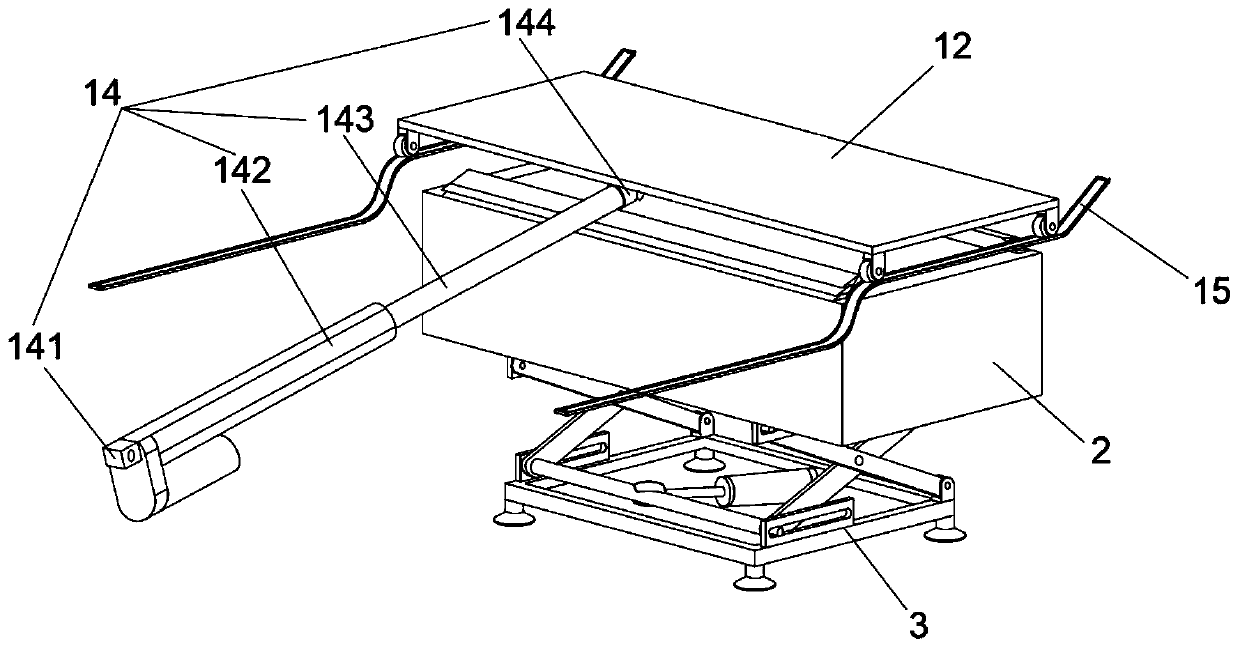

[0033] Such as figure 1 As shown, this embodiment discloses a sweeping machine roller brush self-cleaning device, including a ground opening and closing mechanism 1, a cleaning mechanism 2 and a lifting mechanism 3; the ground opening and closing mechanism 1 includes a first fixed panel 11, a moving panel 12, a second Two fixed panels 13, power assembly 14, slide rail 15 and pulley 16; figure 1 As shown, above the moving panel 12 is the roller brush of the sweeping machine. In the initial state, the roller brush of the sweeping machine is in contact with the moving panel 12, and the bristles are bent to a certain extent under the influence of pressure. The upper and lower surfaces of the first fixed panel 11 and the second fixed panel 13 overlap, leaving a gap in the width direction, and the movable panel 12 can move relative to the gravitational direction of the first fixed panel 11 and the second fixed panel 13 .

[0034] Such as figure 2 As shown, the slide rail 15 is ar...

Embodiment 2

[0042] Such as Image 6 As shown, the difference between the present embodiment and the first embodiment is that the top of the water tank 21 is provided with a limit rubber strip 211, and the limit rubber strip 211 is provided with an upper end inclined to the middle of the water tank 21; wherein the limit rubber strip 211 can be used Rubber strips are not limited to rubber strips. You can also use a water-removing structure such as a strip-based brush structure to ensure that the bristles on the roller brush can be fully dewatered and cleaned, and avoid excessive moisture from damaging the garbage box and air guide channel of the sweeper. Pollution, dust agglomerates.

[0043] Further, the four corners of the bottom of the chassis 31 are also installed with feet 311; through the setting of the feet 311, the feet 311 are in contact with the ground to support the whole mechanism.

Embodiment 3

[0045] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the inside of the water tank 21 in this embodiment has a slope structure module design, that is, in fact, part of the volume of the water tank 21 has been filled with other objects during the water injection process to avoid waste of water resources. At the same time shorten the water injection time and improve efficiency. The material filling part has a smooth slope and the lowest point, and the lowest point is a water outlet, so that all the water in the water tank 21 can flow out after cleaning is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com