Upper-side light-load single-weld-joint cargo boom

A technology for light loads and booms, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems that affect the strength of the boom, not safe and reliable, easy to open welding accidents, etc., so that it is not easy to open welding and save materials, and the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

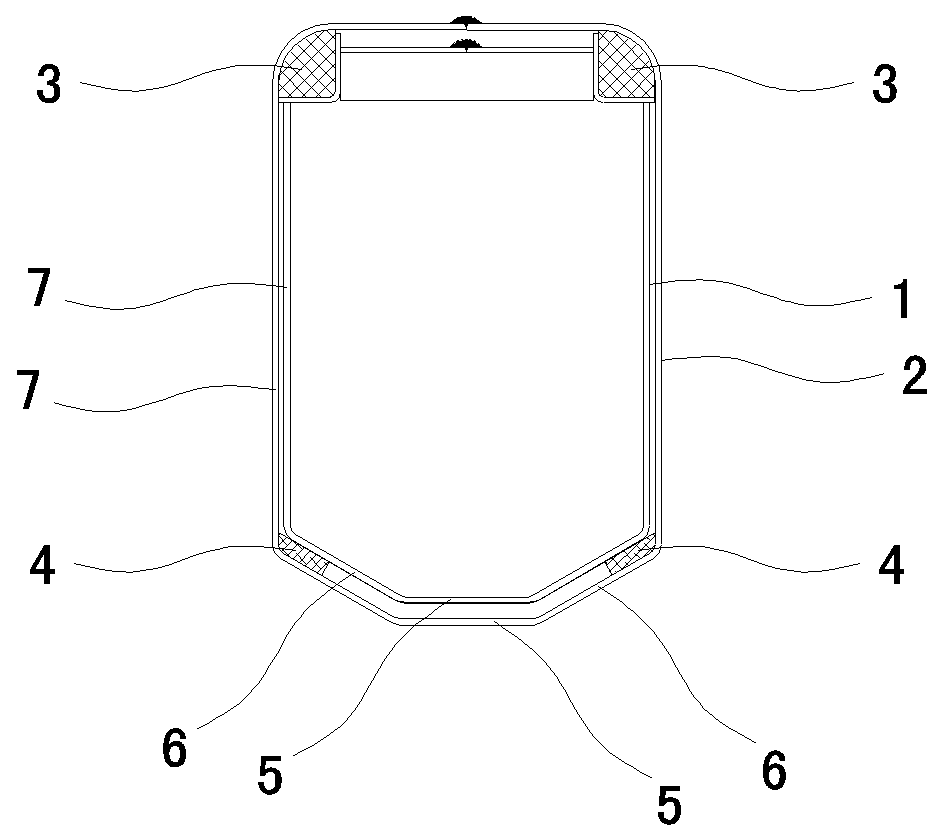

[0011] Example one, such as figure 1 As shown, it includes an inner arm 1 and an outer arm 2. The inner arm 1 is sleeved in the outer arm 2 along the extension direction of the hollow cavity of the outer arm 2. The two upper corner positions of the rear end of the inner arm 1 are respectively provided with the outer The upper sliding wear block 3 of the upper side of the arm 2 is slidingly matched with the two inner corners. The lower inner wall of the front end of the outer arm 2 is provided with a lower sliding wear block 4 that is slidingly matched with the lower outer wall of the inner arm 1. The inner arm 1 and the outer arm 2 are respectively hollow cylindrical bodies with butt edges folded from steel plates located in the middle of the upper side. The inner arm 1 and the outer arm 2 are welded into a whole at the middle butt sides of the upper side.

[0012] The butting edges of the inner arm 1 and the outer arm 2 are respectively set at the middle positions of the upper si...

Embodiment 2

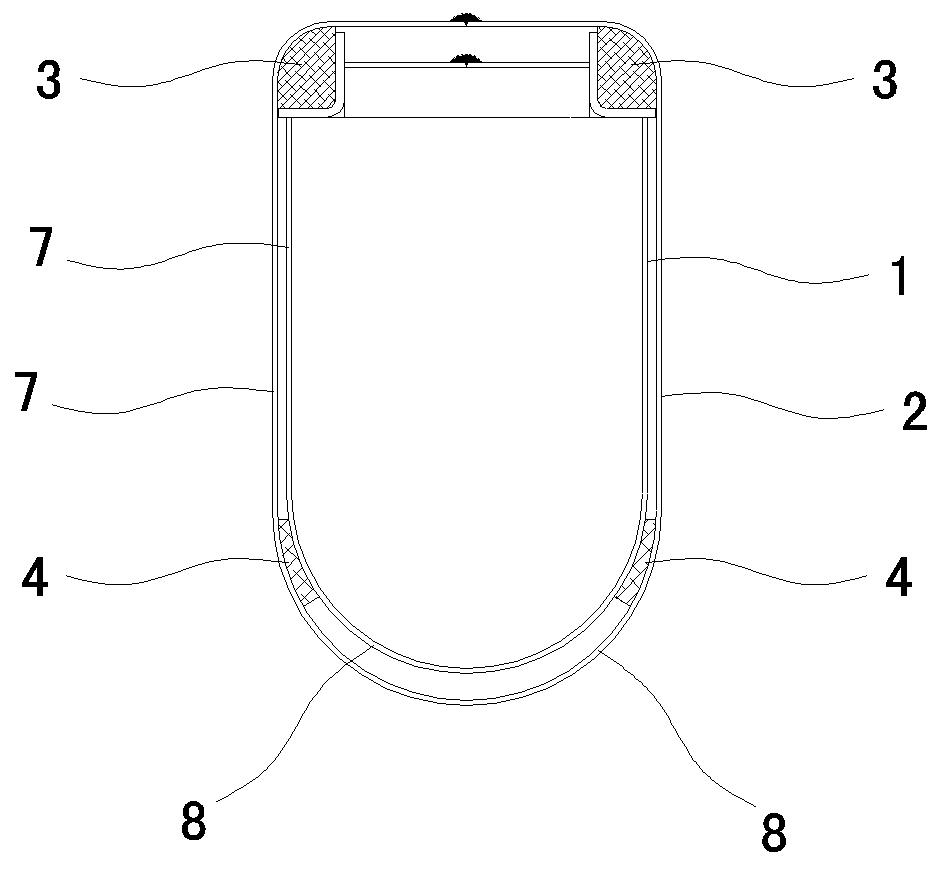

[0015] Example two, such as figure 2 As shown, the difference from the first embodiment is that the lower sides of the inner arm 1 and the outer arm 2 are the 180-degree arc-shaped surface 8 and the 180-degree arc-shaped surface 8 along the direction of the cavity of the inner arm 1 in the axial direction. The sides of the sides extend upward and parallel to each other, forming two left and right elevations 7, and the upper sides of the two elevations 7 are bent in a 90-degree arc shape. The surfaces of the grinding block 3 and the two inner corners on the upper side of the outer arm 2 are 90-degree arc-shaped surfaces, and the high points on both sides of the 180-degree arc-shaped surface 8 at the front end of the outer arm 2 are respectively provided with a lower slide The wear-resistant block 4 or the 180-degree arc-shaped surface 8 of the front end of the outer arm 2 is provided with a lower sliding wear-resistant block 4 of integral structure.

Embodiment 3

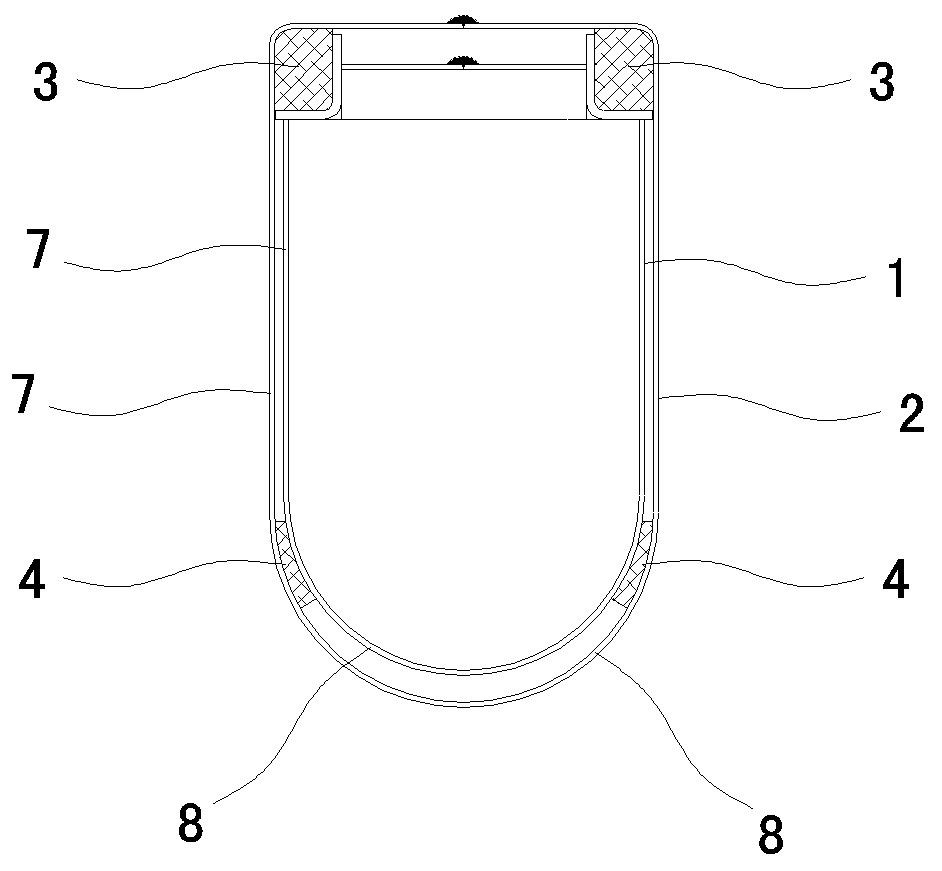

[0016] Example three, such as image 3 As shown, the difference from the first embodiment is that the lower sides of the inner arm 1 and the outer arm 2 are the 180-degree arc-shaped surface 8 and the 180-degree arc-shaped surface 8 along the direction of the cavity of the inner arm 1 in the axial direction. The sides of the sides extend upward and parallel to each other to form the left and right elevations 7 of the inner arm 1. The upper sides of the two elevations 7 are bent at right angles to each other. The surfaces of the grinding block 3 and the two inner corners on the upper side of the outer arm 2 are right-angled surfaces, and a lower sliding wear-resistant block is provided on both sides of the high point of the 180-degree arc-shaped surface 8 at the front end of the outer arm 2 respectively 4. Or the 180-degree arc-shaped surface 8 of the front end of the outer arm 2 is provided with a lower sliding wear block 4 of integral structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com