Foundation pit supporting-free prefabricated support pile single-row construction method and middle inclined pile press machine

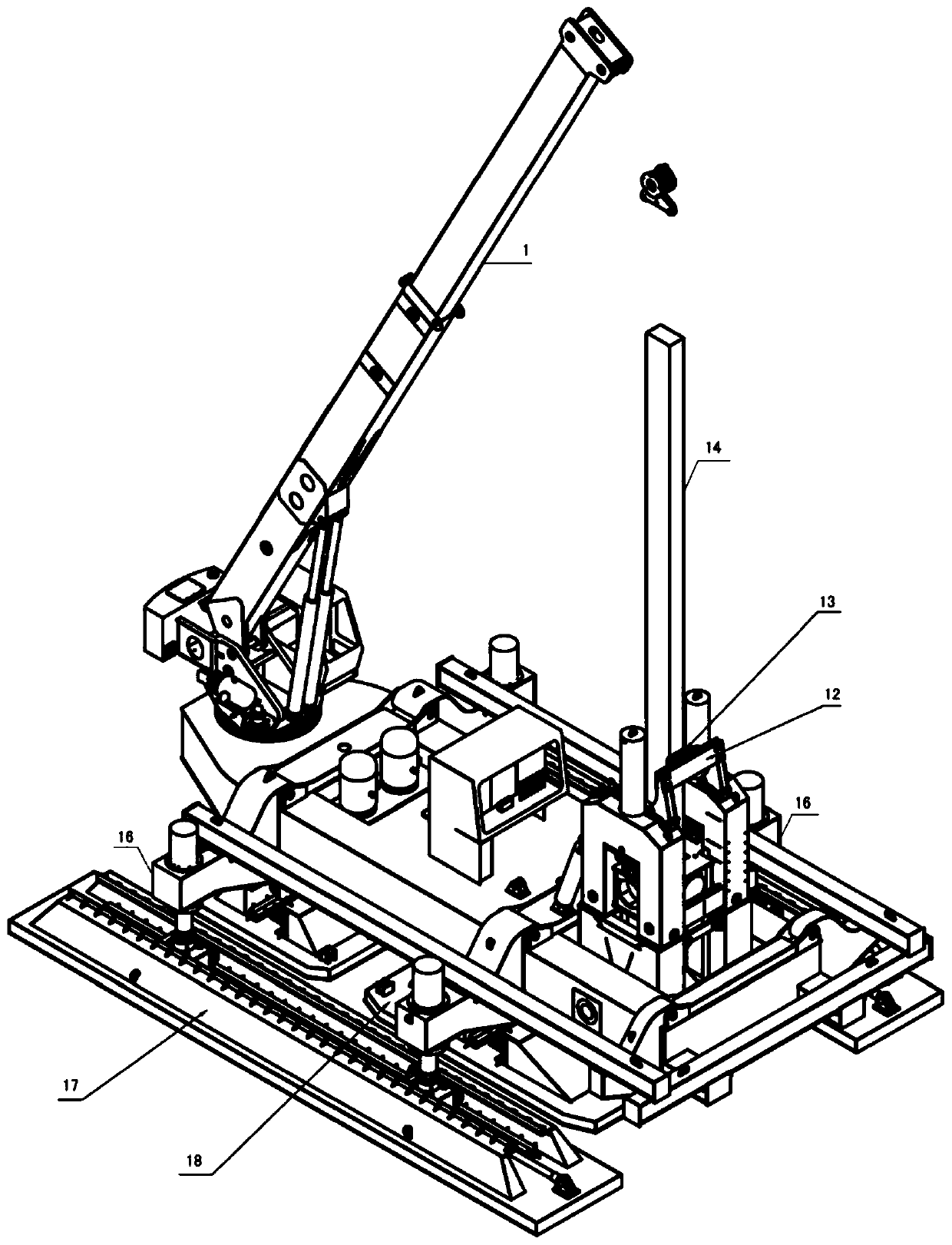

A construction method and a technology for supporting piles, which are applied in the field of hydraulic pile drivers, can solve the problems of affecting the moving machine or moving speed, long time-consuming moving, low construction efficiency, etc., and achieve expanded application range, fast moving speed, The effect of high piling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

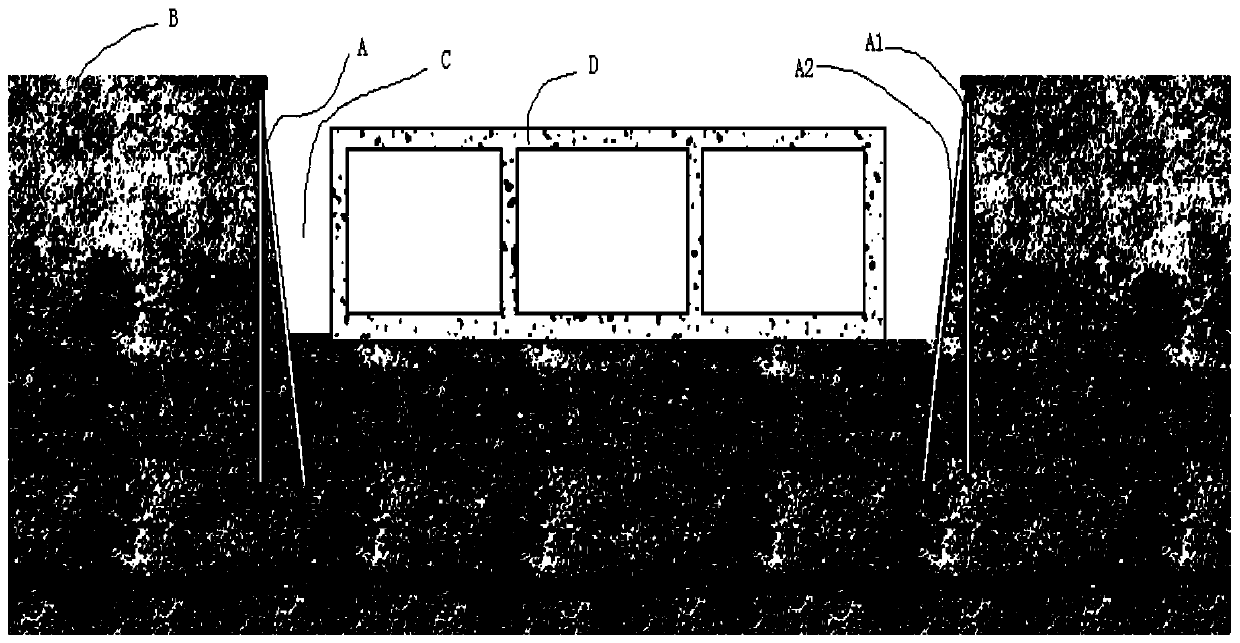

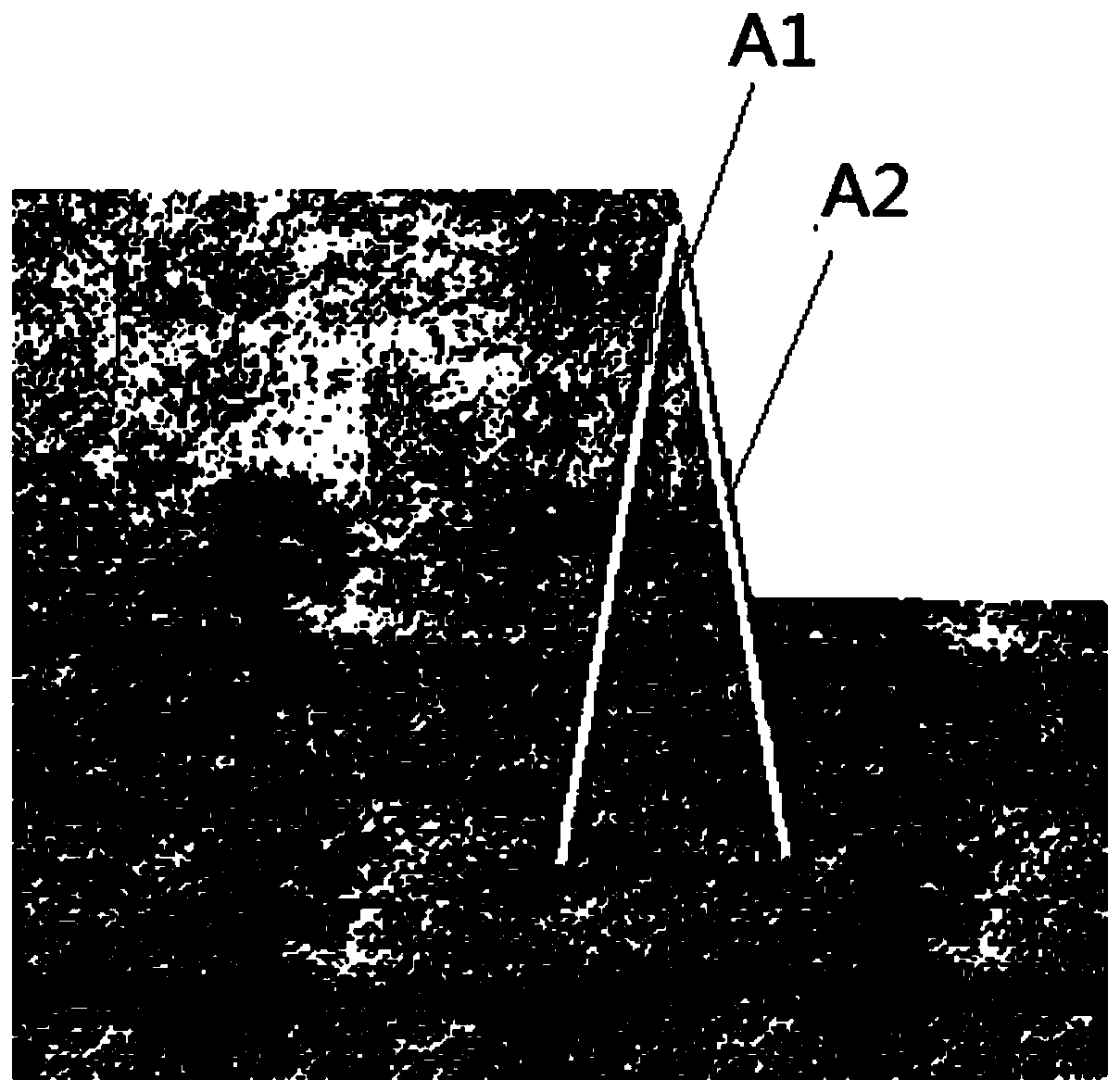

[0059] See attached Figure 2-8 , a single-row construction method for unsupported prefabricated inclined pile support in foundation pits provided in this embodiment in the construction of urban pipe corridors and other projects. The specific construction requirements are to excavate a length of 2 The foundation pit C with a depth of 8-10 meters is used to lay the prefabricated urban comprehensive pipe gallery D; the single-row construction method of unsupported prefabricated inclined pile support, the middle-mounted inclined pile pile driver, and the prefabricated cement pile for support are adopted. Construction, unsupported prefabricated inclined piles supporting single row piles in some construction sites, each group includes 2 supporting piles A, which are the first type of outer inclined pile A1+straight pile A2, or the second type of outer inclined pile A1+inner inclined pile A2: Unsupported prefabricated inclined piles supporting single row piles in some construction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com