Cutter device of shield tunneling machine

A shield machine tool and shield machine technology, applied in the field of shield machines, can solve the problems of displacement use of internal output groups, high cost requirements, and failure to meet heat dissipation requirements, and achieve the effect of preventing displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

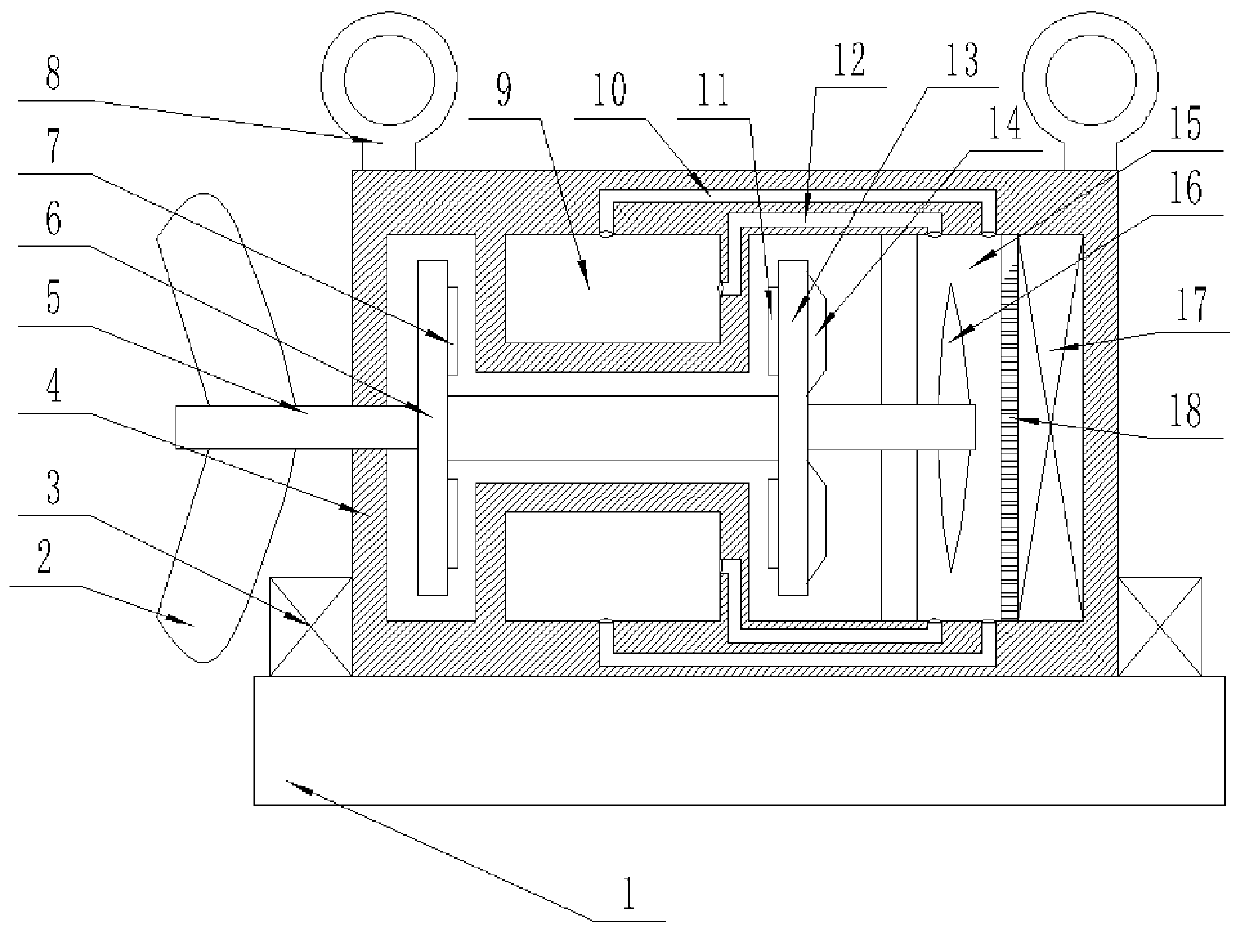

[0020] Such as figure 1 , This specific embodiment adopts the following technical solutions: a shield machine tool device, including a shield machine base 1, a blade 2, an anti-displacement fixed plate 3, a waterproof outer cover 4, a rotating shaft 5, a first rotating plate 6, and a first coil 7. Lifting ring 8, cooling groove 9, first pipe 10, second coil 11, second pipe 12, second rotating plate 13, permanent magnet 14, return tank 15, magnetic transmission wheel 16, refrigeration device 17, and temperature guide plate 18; The blade 2 is fixedly connected to the rotating shaft 5; the upper surface of the shield machine base 1 is fixedly connected with a waterproof cover 4, the left and right ends of the waterproof cover 4 are provided with anti-displacement fixing plates 3; the waterproof cover 4 Both sides of the upper end are fixedly connected with a lifting ring 8; the inner right end of the waterproof housing 4 is provided with a refrigeration device 17, and the left end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com