Driving circuit of quick tripping relay

A technology for driving circuits and relays, applied to relays, circuits, electrical components, etc., can solve the problem of reducing the pull-in time and achieve the effect of shortening the pull-in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

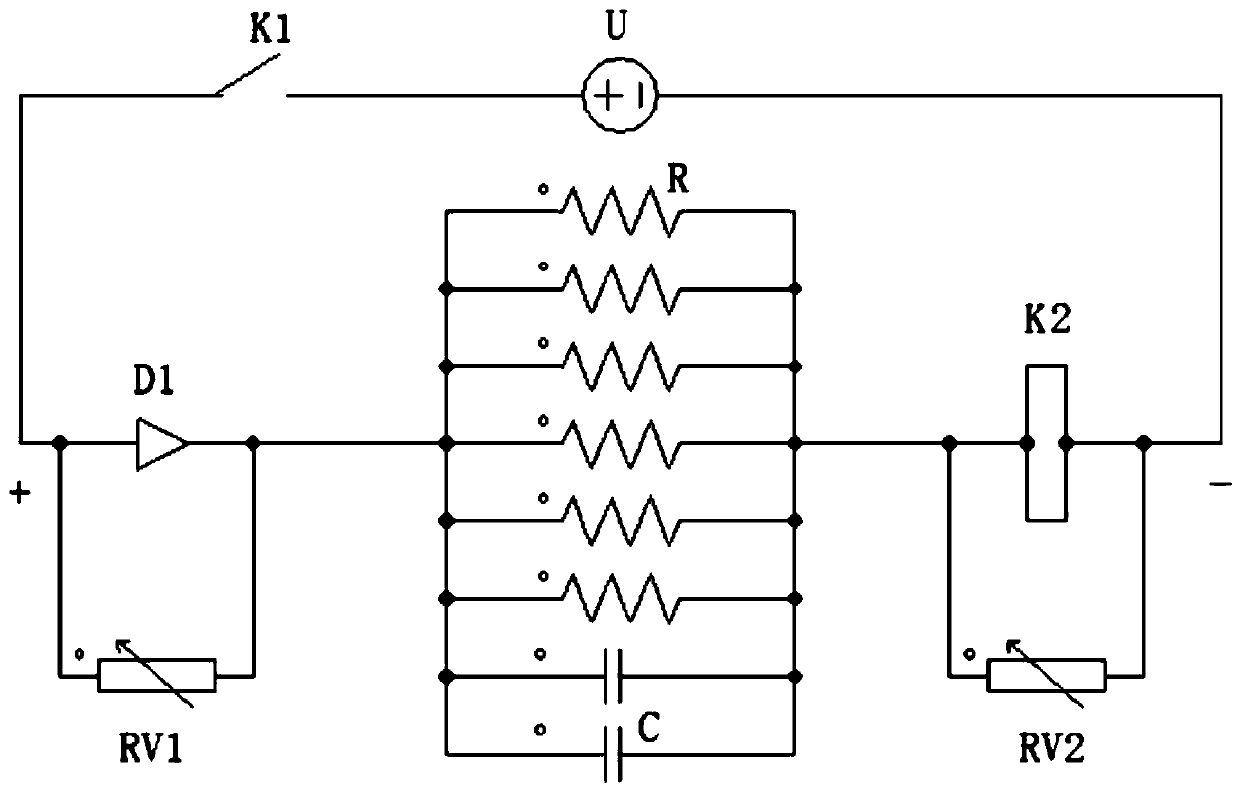

[0017] Please refer to figure 1 As shown, a driving circuit of a fast tripping relay in this embodiment includes a 110V DC voltage source U, a switch K1, a coil K2 with a rated operating voltage of 16V, six resistors R with a resistance value of 18KΩ, two Capacitor C with capacitance value of 22uF, diode D1, varistor RV1 and varistor RV2. When the relay needs to work, close the switch K1, so that the 110V DC voltage source U is connected; when the relay does not need to work, turn off the switch K1, and the relay stops working.

[0018] Six resistors R and two capacitors C are connected in parallel to form an RC parallel circuit, the DC voltage source U is connected to the anode of the diode D1 through the switch K1, the cathode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com