Display panel cutting stage cleaning device and display panel manufacturing equipment

A display panel and cleaning device technology, applied in cleaning methods and tools, cleaning methods using tools, cleaning methods using gas flow, etc., can solve the problems of uneven pressure applied to cutting stages, secondary pollution of cutting stages, etc. , to achieve the effect of avoiding secondary pollution, improving the degree of bonding, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

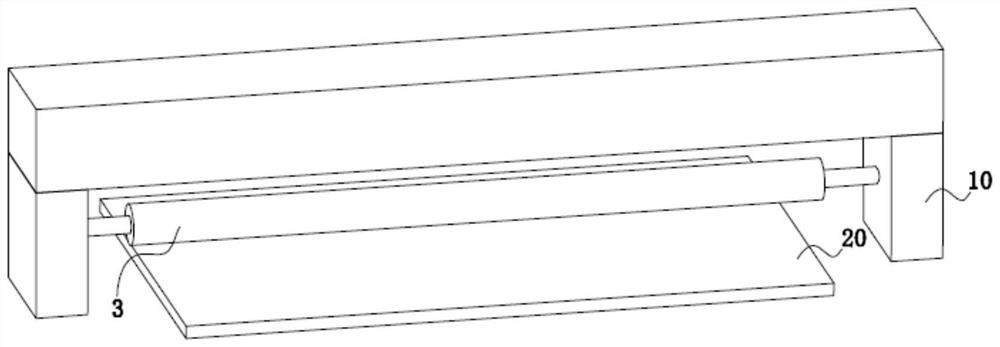

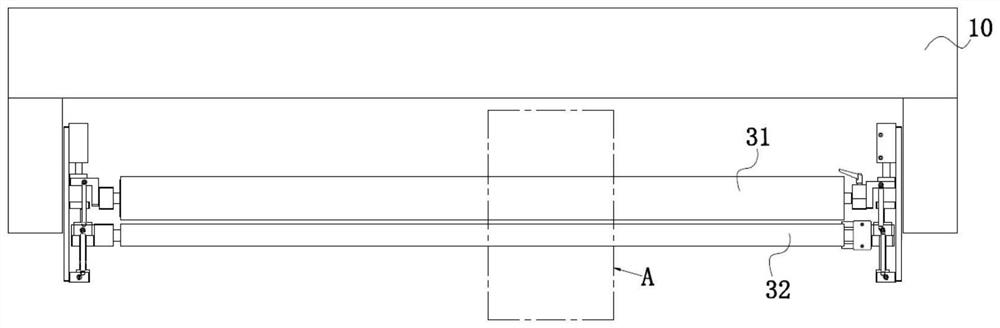

[0042] ginseng Figure 2 to Figure 3 and Figure 5 to Figure 6 Shown is a specific implementation of a display panel cutting stage cleaning device of the present invention. A display panel cutting stage cleaning device (hereinafter referred to as "cleaning device") disclosed in this embodiment can not only clean the display panel cutting stage (hereinafter referred to as "cutting stage"), but also clean other Various cutting stages or stages are used for cleaning operations, and objects carried by the cutting stages or stages include not only display panels, but also wafers, gallium nitride wafers, or wafers containing arsenic and potassium.

[0043] The display panel cutting stage cleaning device disclosed in this embodiment includes:

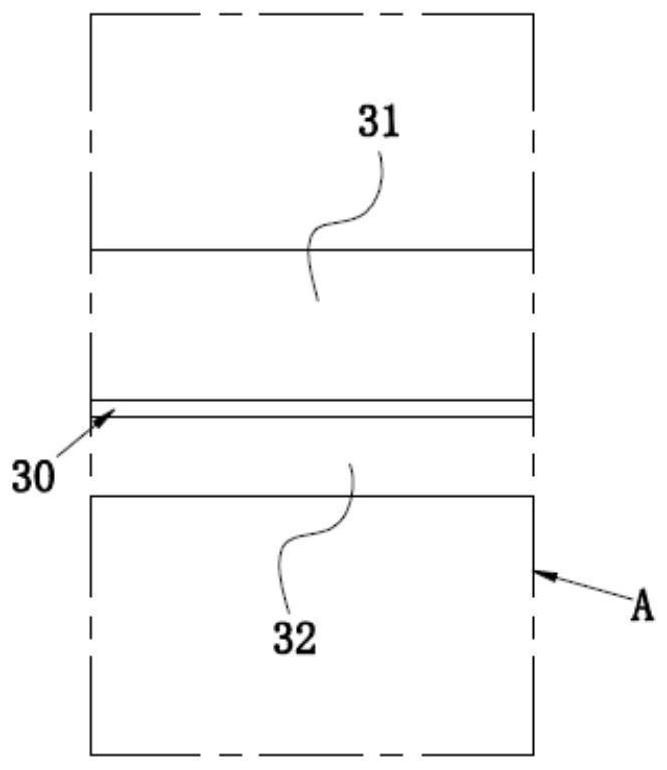

[0044] The gantry 10 is placed horizontally on the gantry 10 and consists of a cleaning roller set composed of a first roller 31 and a second roller 32 arranged up and down, and a limiting mechanism for fixing the axial ends of the cleaning ...

Embodiment 2

[0057] ginseng Figure 7 A first variant embodiment of a cleaning device of the invention is shown. The main difference between the cleaning device shown in this embodiment and the cleaning device disclosed in Embodiment 1 is that the cleaning device disclosed in this embodiment includes an adjustment component 40b.

[0058] The adjustment assembly 40b shown in this embodiment is relative to Figure 6 Compared with the adjustment assembly 40a shown, the main difference is that the adjustment assembly 40b also includes a second fixing seat 403a arranged between the first mounting seat 42 and the second mounting seat 410, and a longitudinally arranged guide shaft 404 . The guide shaft 404 vertically passes through the second mounting base 410 and at least supports above the first fixing base 411 . One end of the second fixing base 403 a is fixed on the mounting plate 401 , and the other end can be separated from the first mounting base 42 or can be in contact with the first m...

Embodiment 3

[0064] This embodiment shows a modified example of a display panel cutting stage cleaning device of the present invention.

[0065] ginseng Figure 4 , Figure 8 and Figure 9 As shown, the main difference between the cleaning device disclosed in this embodiment and the cleaning device disclosed in embodiment 1 and / or embodiment 2 is that the cleaning device disclosed in this embodiment includes such Figure 8 Adjustment assembly 40c is shown.

[0066] One or more second telescopic members 405 are arranged between the first mounting seat 42 and the second mounting seat 410 included in the adjustment assembly 40c, and the second telescopic members 405 exert tension on the first mounting seat 42 and the second mounting seat 410 F2; one or more third telescopic members 406 are disposed between the second mounting base 410 and the first fixing base 411 , and the third telescopic members 406 apply a pulling force F3 to the second mounting base 410 . The second telescopic member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com