A kind of electric machine tool coolant temperature automatic adjustment device

A cooling liquid temperature, automatic adjustment technology, applied in the direction of metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of unstable workpiece precision, shortened tool life, temperature rise, etc., to reduce temperature, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

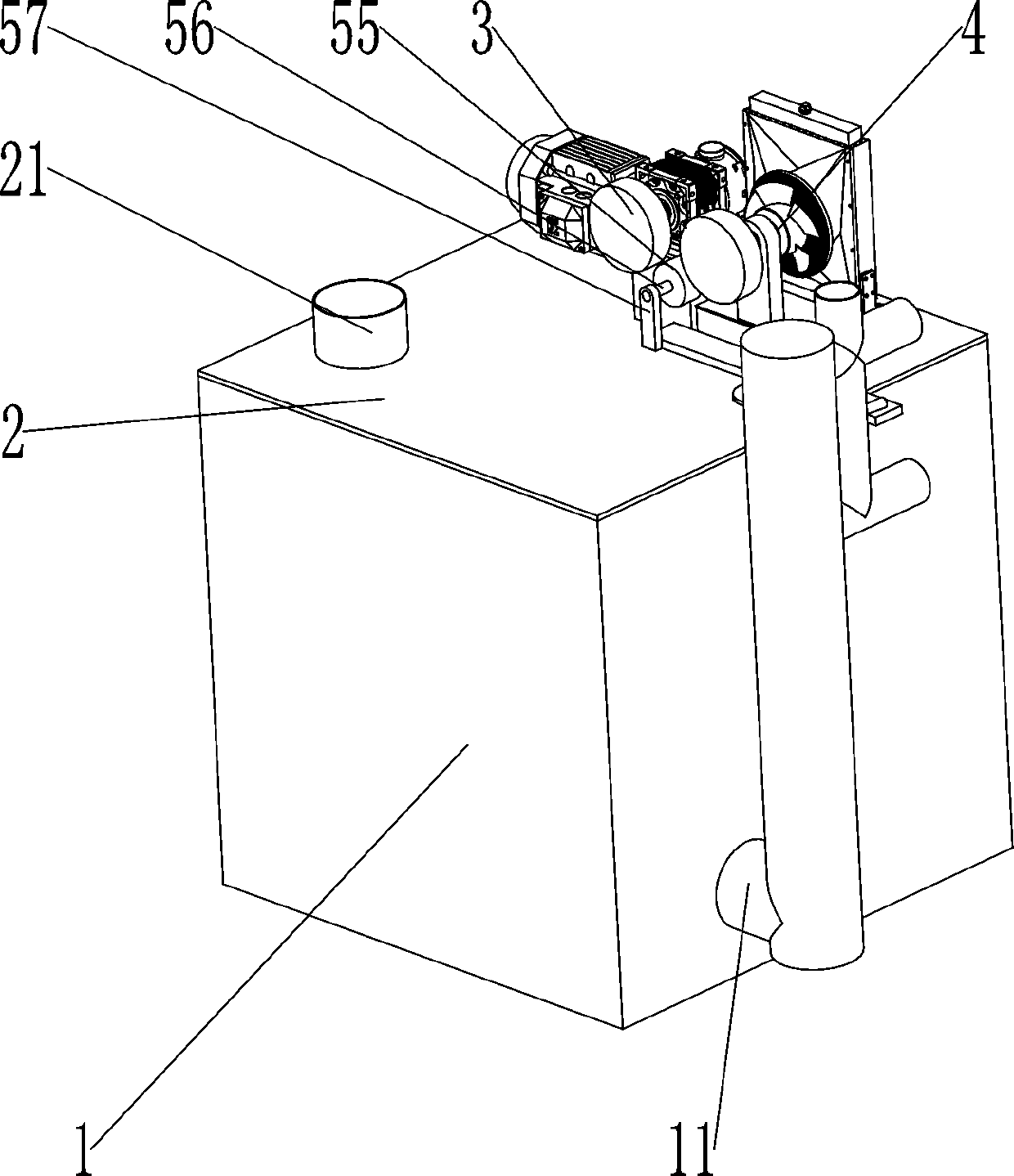

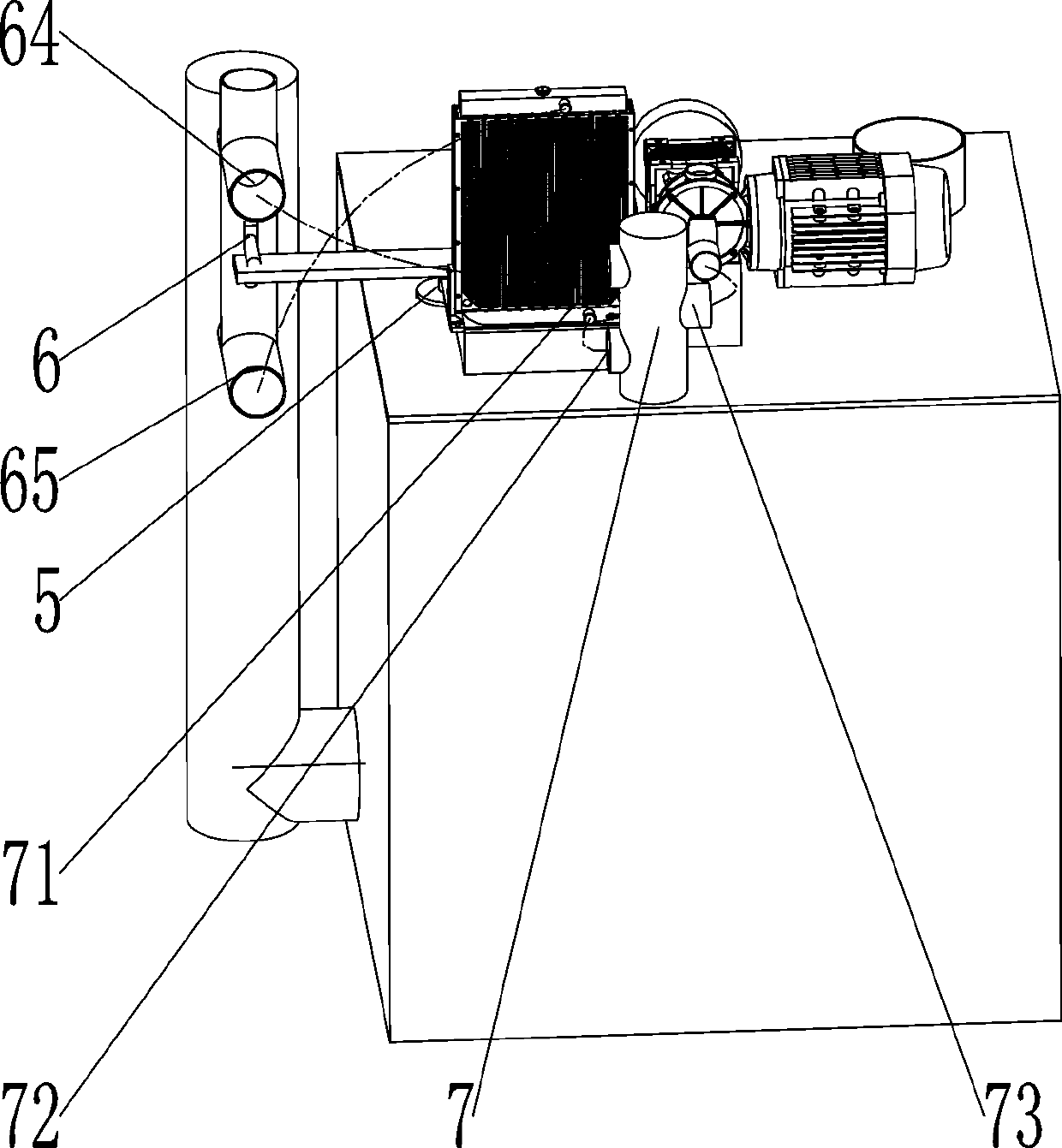

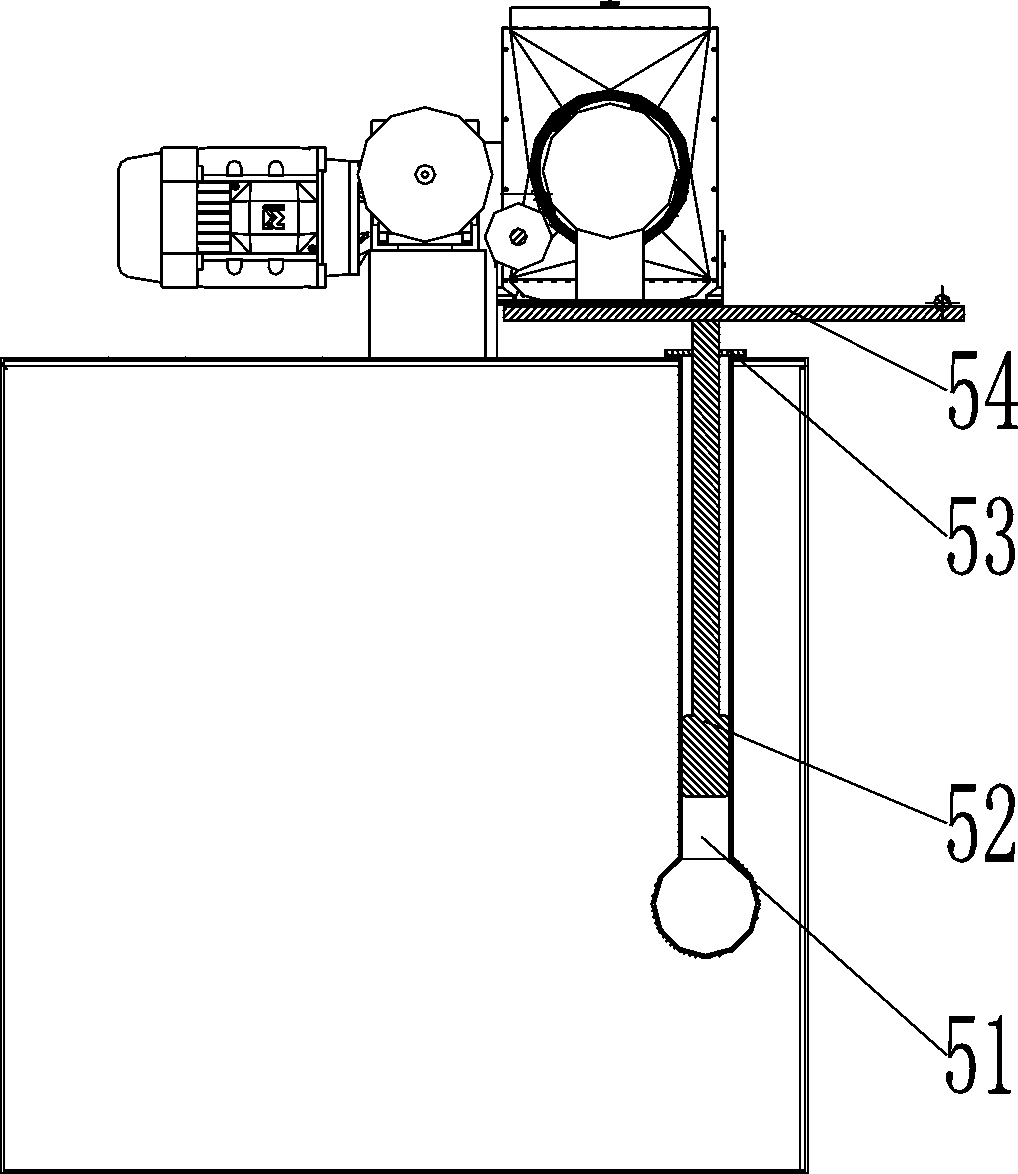

[0022] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 6 , an automatic adjustment device for coolant temperature of an electric machine tool, the box cover 2 is fixed on the upper part of the box body 1, the linkage switch mechanism 6 is arranged on one side of the box body 2, the water pump mechanism 3, The cooling water tank mechanism 4 , the mercury temperature ejector mechanism 5 and the tee pipe 7 are all arranged on the upper surface of the tank cover 2 .

[0023] The side of the box 1 is provided with a box water outlet 11, the connecting part of the linkage switch mechanism 6 is threadedly connected with the box water outlet 11, and the two-way plug piston 61 is arranged on the piston switch of the pipeline 62. Inside the tube, the interlocking piston connecting rod 63 is fixed in the middle of the two-way plug piston 61 , and is slidably connected to the long slot o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com