Nylon 66 material of hydrophilic group modified organic silicon polymer

A technology of organosilicon and polymer, applied in the field of nylon 66, can solve problems such as cracked materials, affecting the application effect of organosilicon compounds, precipitation, etc., and achieve the effect of reducing the probability of fire and excellent physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

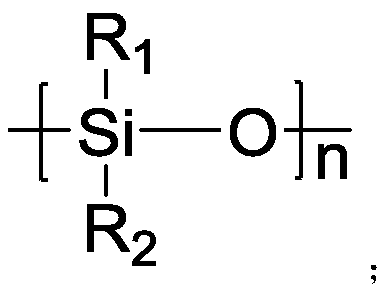

Method used

Image

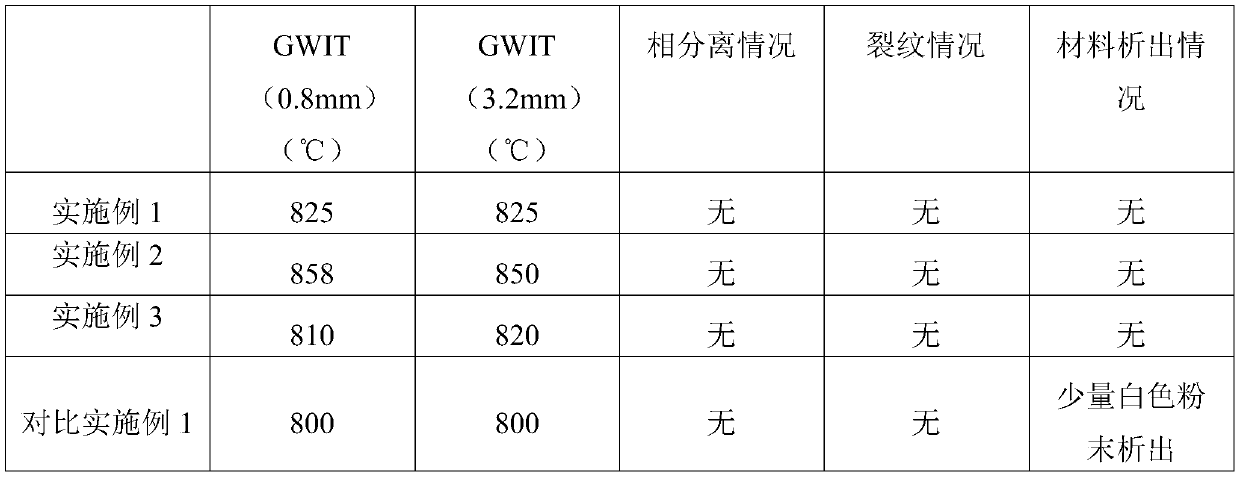

Examples

Embodiment 1

[0030] A kind of nylon 66 material with the organosilicon polymer of hydrophilic group modification, comprises following composition by weight:

[0031]

[0032] in, The degree of polymerization is 10, the graft ratio of maleic anhydride in the graft copolymer of maleic anhydride and polypropylene is 10%, and the polymer is 10.

[0033] The preparation method comprises the following steps:

[0034] will be based on the above mass parts The graft copolymer of maleic anhydride and polypropylene, nylon 66 resin and glass fiber are physically blended at 200°C to form a product;

[0035] The obtained nylon 66 material having a silicone polymer modified by a hydrophilic group had a particle size of 3000 mesh.

Embodiment 2

[0037] A kind of nylon 66 material with the organosilicon polymer of hydrophilic group modification, comprises following composition by weight:

[0038]

[0039]

[0040] in, The degree of polymerization is 100, the graft ratio of maleic anhydride in the graft copolymer of maleic anhydride and polypropylene is 30%, and the polymer is 10.

[0041] The preparation method comprises the following steps:

[0042] will be based on the above mass parts The graft copolymer of maleic anhydride and polypropylene, nylon 66 resin and glass fiber are physically blended at 200°C to form a product.

[0043] The obtained nylon 66 material having the silicone polymer modified by the hydrophilic group had a particle diameter of 10000 mesh.

Embodiment 3

[0045] A kind of nylon 66 material with the organosilicon polymer of hydrophilic group modification, comprises following composition by weight:

[0046]

[0047] in, The degree of polymerization is 50, the graft ratio of maleic anhydride in the graft copolymer of maleic anhydride and polypropylene is 10%, and the polymer is 10%.

[0048] The preparation method comprises the following steps:

[0049] will be based on the above mass parts The graft copolymer of maleic anhydride and polypropylene, nylon 66 resin and glass fiber are physically blended at 200°C to form a product;

[0050] The obtained nylon 66 material having a hydrophilic group-modified silicone polymer had a particle size of 7000 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com