A structure and construction method of a combined girder bridge with external support girder type maintenance road

A girder bridge with external braced girders and construction method technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as increasing the difficulty of concrete pouring and hoisting, increasing the self-weight of bridge structures, and large structural dimensions of maintenance roads , to achieve the effect of shortening the construction period, reducing the cost of materials used, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

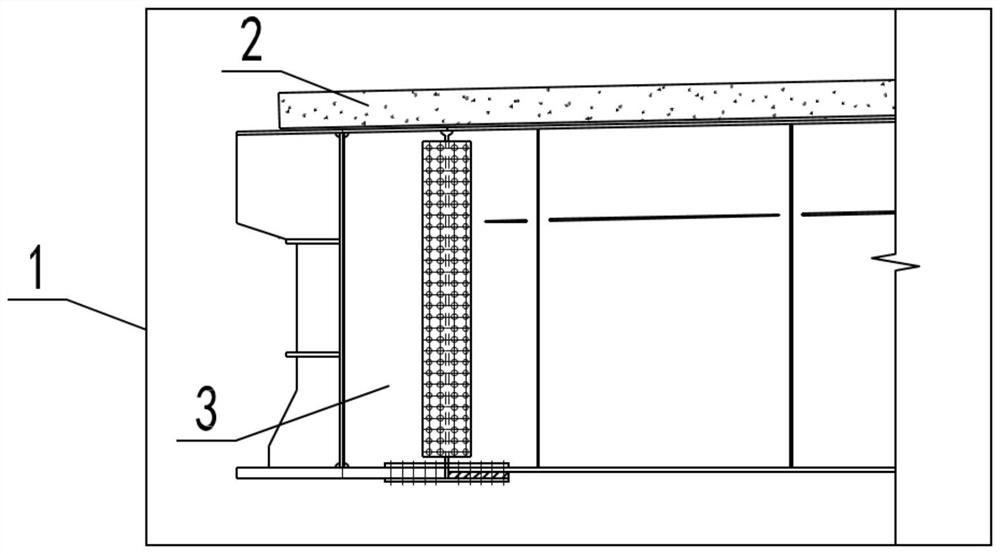

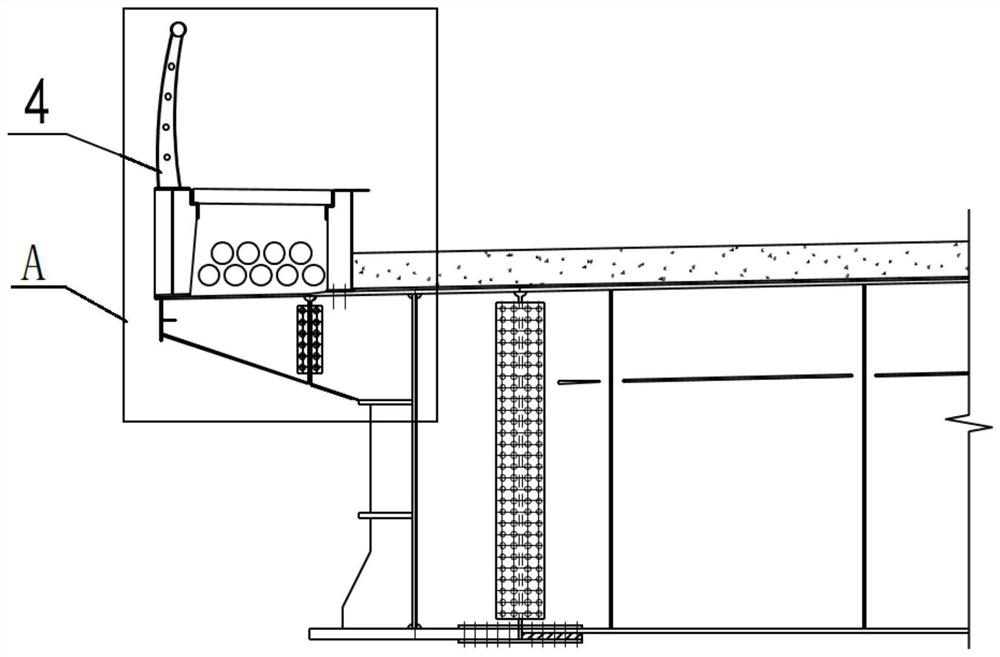

[0038] see Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a combined girder bridge external support beam type inspection road structure, including:

[0039] The support beam 22 is fixedly connected to the left and right sides of the combined beam bridge 1 , the combined beam bridge 1 includes a steel beam 3 and a concrete bridge deck 2 , and the concrete bridge deck 2 is laid on the top of the steel beam 3 . This supporting beam 22 is provided with many, and many supporting beams 22 are connected with the steel girder 3 of combined beam bridge 1; The spacing is 3.5m.

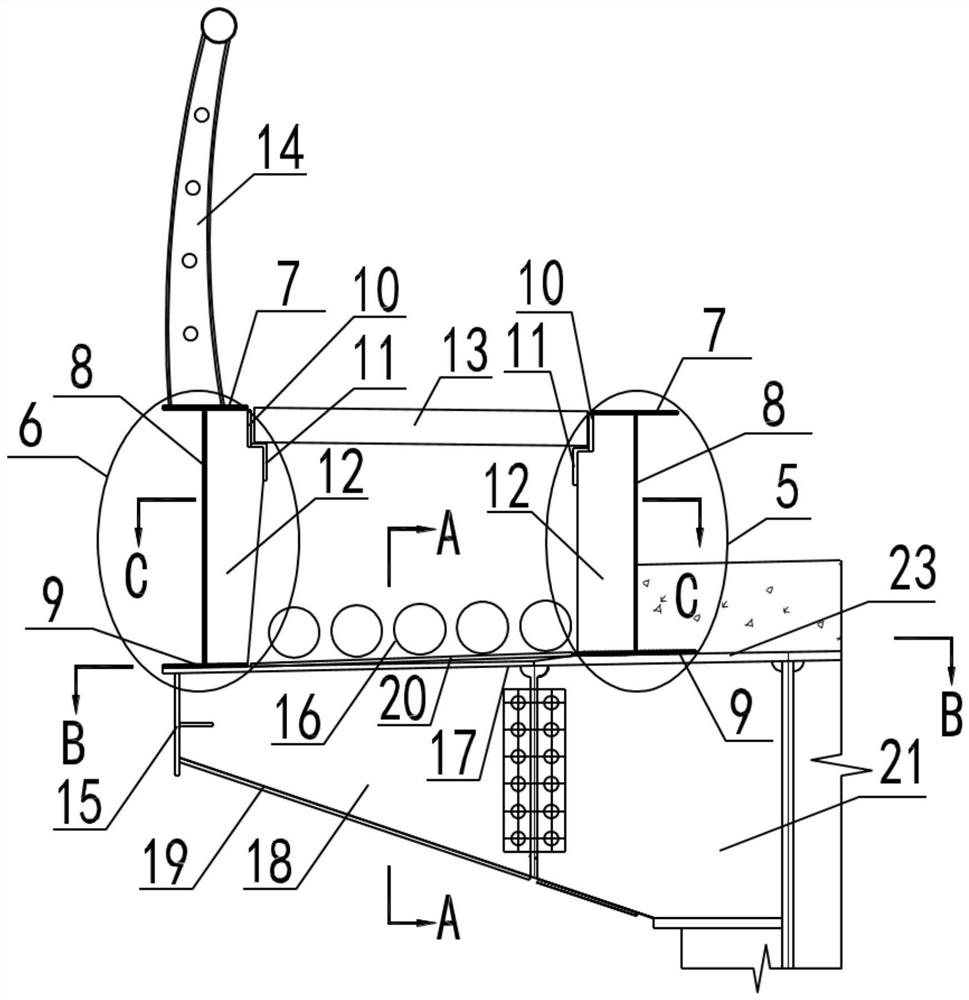

[0040] The support beam 22 comprises a support beam top plate 17, a support beam web 18 and a support beam bottom plate 19, the support beam top plate 17 is vertically connected to the top of the support beam web 18, and the support beam bottom plate 19 is vertically connected to the bottom of the support beam web 18. The support beam web 18 is a right-angled trapezoidal struc...

Embodiment 2

[0047] see image 3 As shown, the embodiment of the present invention provides a combined girder bridge with external support girder type inspection road structure. The difference between this embodiment and embodiment 1 is that: the first longitudinal beam 5 and the second longitudinal beam 6 are fixedly connected Beam vertical stiffener 12, the longitudinal beam vertical stiffener 12 on the first longitudinal beam 5 is located on the side close to the second longitudinal beam 6, the longitudinal beam vertical stiffener 12 on the second longitudinal beam 6 is located close to the first longitudinal beam 5 One side of the longitudinal beam vertical stiffener 12 is provided with a plurality of longitudinal beam vertical stiffeners 12 arranged at intervals along the length direction of the first longitudinal beam 5 and the second longitudinal beam 6 in an array, and the adjacent two longitudinal beam vertical The spacing between stiffening plates 12 is 0.5 m.

[0048] An L-shap...

Embodiment 3

[0050] see image 3 with Image 6 As shown, the embodiment of the present invention provides a combined girder bridge with external support girder type inspection road structure. The difference between this embodiment and embodiment 1 is that: the top of the support beam 22 is also equipped with a steel grating plate 20, and the steel grating The grid plate 20 is located between the first longitudinal beam 5 and the second longitudinal beam 6, and the steel grid plate has a hollow structure, which not only has high structural strength, but also has strong water permeability to prevent water accumulation. The steel grid plate 20 extends along the longitudinal bridge direction of the combined girder bridge 1 , and the access road plate 13 , the steel grid plate 20 , the first longitudinal beam 5 and the second longitudinal beam 6 form a closed long passageway. A bridge pipeline 16 is provided in the closed long channel enclosed by the inspection road slab 13, the steel grid pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com