Zero-pressure-damage two-way high-speed explosion stop device for pipelines

A pipeline and zero-pressure technology, which is applied in the field of zero-pressure-loss two-way high-speed explosion blocking device, can solve problems such as long closing time, failure of overfire blocking explosion, failure of internal energy storage mechanism, etc., and achieve the effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

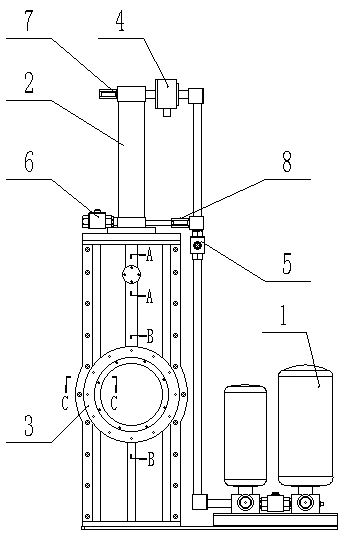

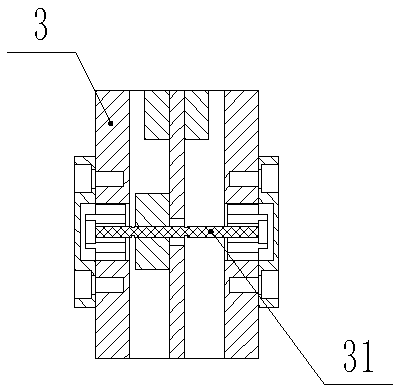

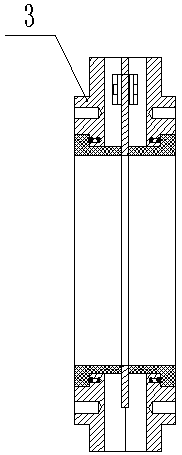

[0042] Such as Figure 1 to Figure 8 As shown, the zero pressure loss two-way high-speed explosion blocking device for pipelines of the present invention includes: an energy storage mechanism 1, a cylinder actuator 2, an explosion-proof gate valve 3, an instant opening valve 4, an opening valve A5, an opening valve B6, a needle Valve A7 and needle valve B8; the energy storage mechanism 1 communicates with the cylinder body actuator 2 through a pipeline, an instant opening valve 4 is arranged on the pipeline, and an explosion-proof gate valve 3 is fixed below the cylinder body actuator 2;

[0043] An opening valve A5 is also provided on the pipeline between the energy storage mechanism 1 and the instant opening valve 4, and an opening valve B6 is provided at the connection between the cylinder actuator 2 and the explosion-proof gate valve 3, and the cylinder actuator 2 A needle valve A7 is provided at the connection with the pipeline, and the lower end of the cylinder actuator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com