Energy storage air bag connecting pipe sealing device and sealing method

A sealing device and air bag technology, which is applied in the direction of pipes/pipe joints/pipe fittings, pipe components, mechanical equipment, etc., can solve the problems of the gap between the air bag and the connecting pipe, the gas volume becomes smaller, and the air bag becomes smaller, so as to achieve good sealing effect and manufacturing Convenient and self-fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

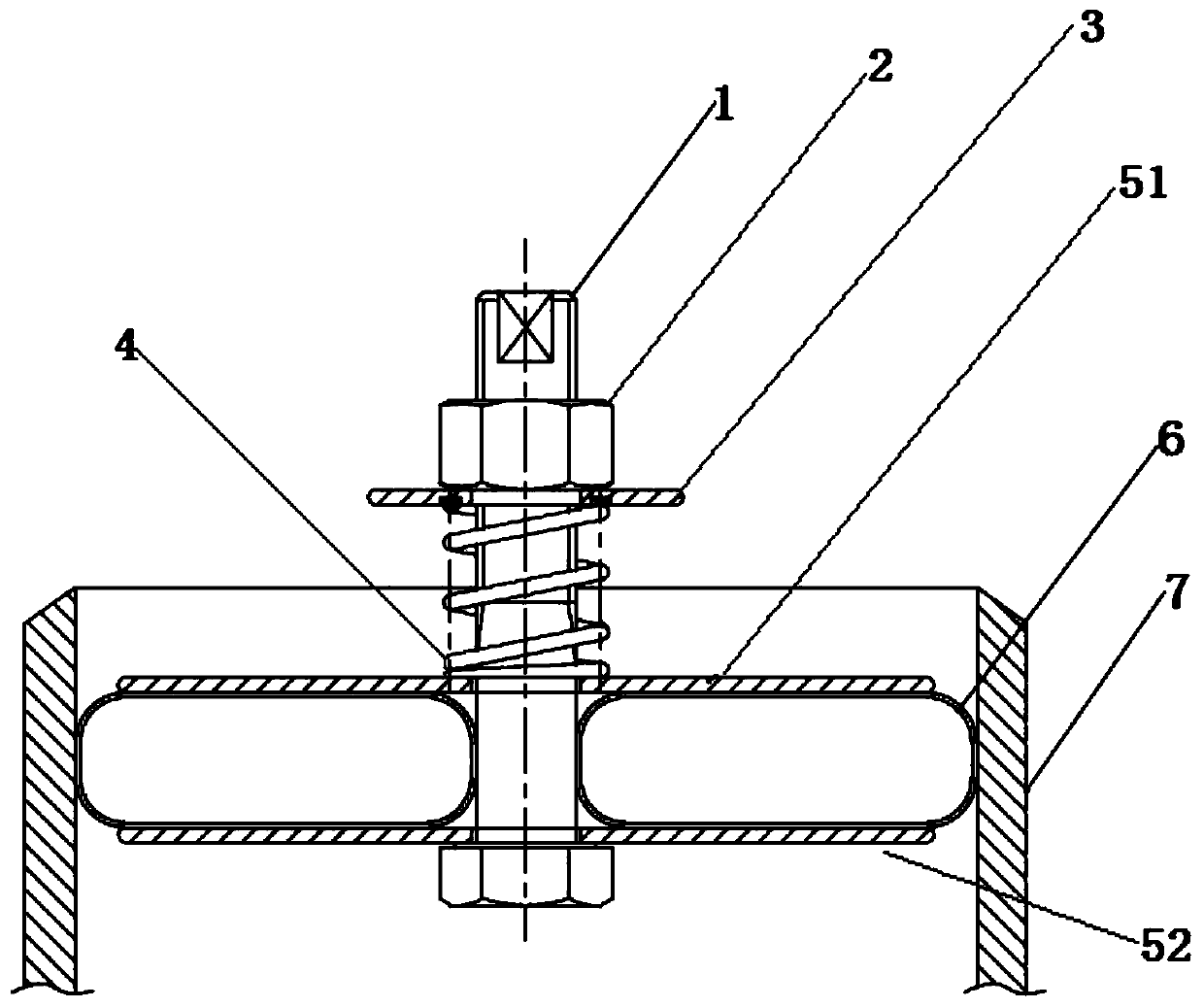

[0061] According to a preferred embodiment of the present invention, the connection between the nut of the bolt 1 and the lower pressure plate 52 in contact with it is a non-detachable connection, which has the advantages of good connection integrity and light structure. Preferably, the connection method between the nut of the bolt 1 and the lower pressure plate 52 in contact with it is adhesive connection or welding connection; more preferably welding connection, especially sealing welding.

[0062] Because the sealing device for the connecting pipe of the energy storage airbag of the present invention is used to seal the connecting pipes in the nuclear power equipment to ensure the cleanliness of the inside of the equipment, generally after the sealing equipment is installed at the connecting pipes, the inside of the equipment will be vacuumed, and then It is filled with inert gas protection, and the inert gas is not easy to react with the metal to protect the dryness and cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com