Paraffin section transferring and developing apparatus, sectioning device and method for paraffin sectioning

A technology for paraffin sectioning and displaying, applied in the field of biomedical experimental instruments, can solve the problems of cumbersome operation, easy curling or damage, high failure rate of paraffin sections, etc., and achieve the effect of high-efficiency displaying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

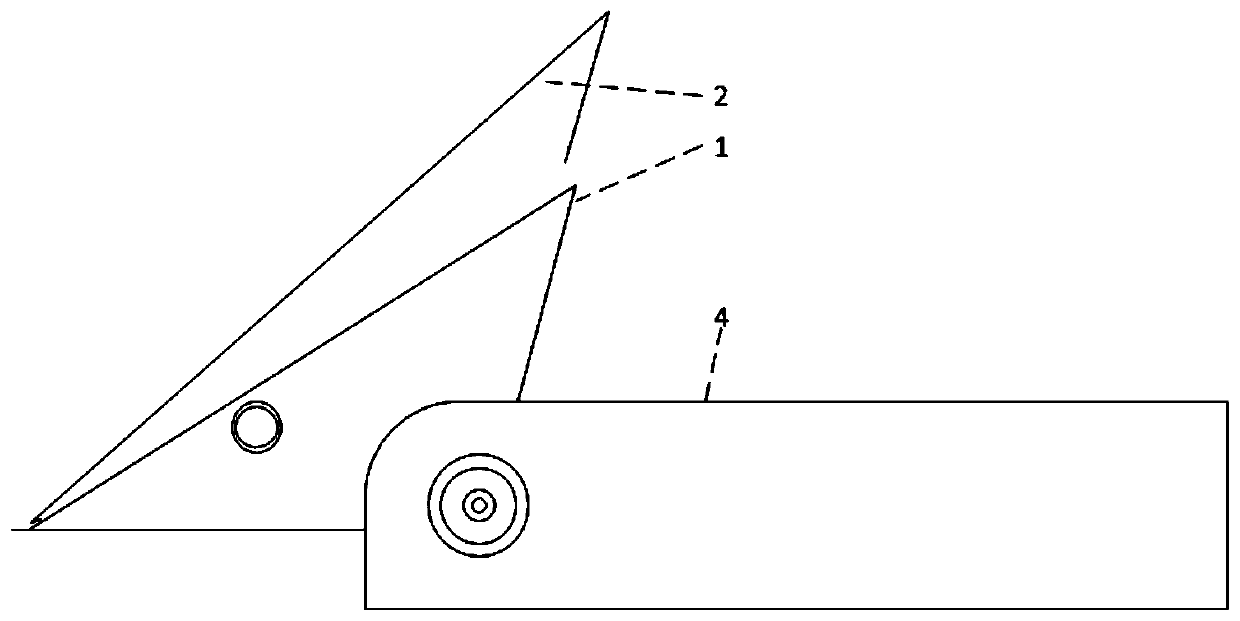

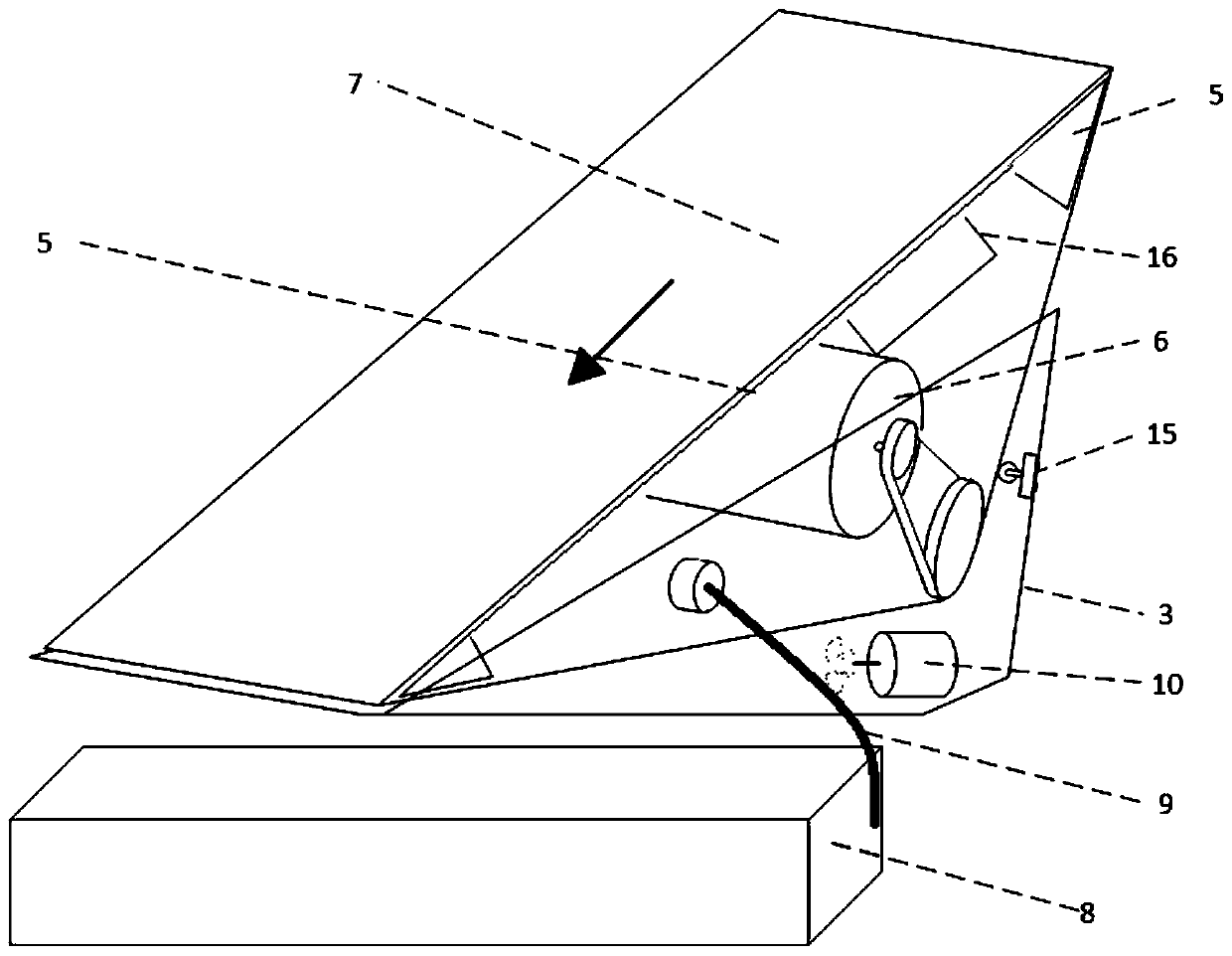

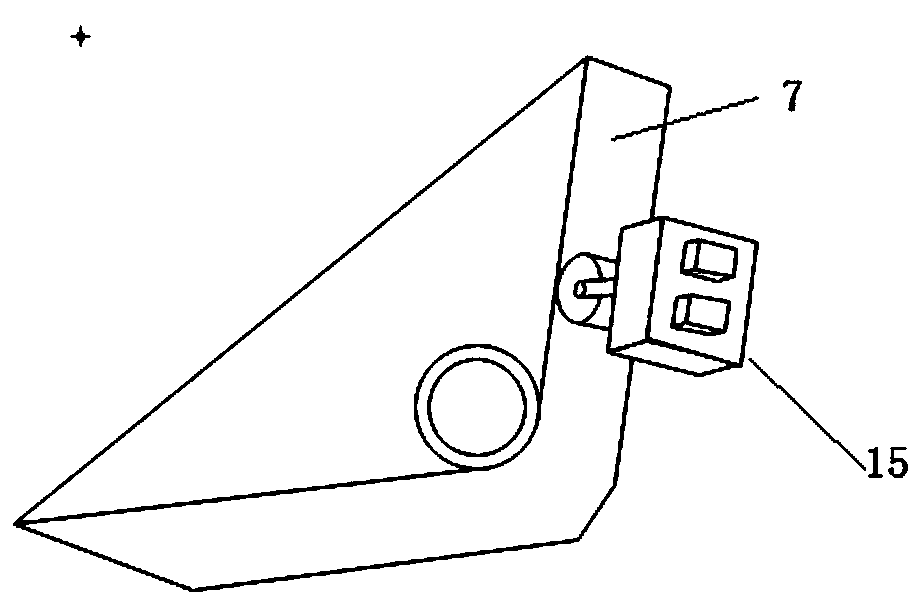

[0042] See attached figure 1 And attached figure 2 As shown, the paraffin section transfer and display apparatus in this embodiment includes a support 1, a transmission mechanism 2, a refrigeration mechanism 8, and an electrostatic mechanism 15. The transmission mechanism 2 includes a conveyor belt 7 and a power unit 6, and the conveyor belt 7 is laid on the side of the support 1. On the surface, the power unit 6 drives the conveyor belt 7 to move, the cold air port of the refrigeration mechanism 8 is placed in the inner space of the bracket 1 below the conveyor belt 7, and the end of the electrostatic mechanism 15 contacts the conveyor belt 7 to charge or eliminate static electricity. In order to ensure the stability of the paraffin section transfer and display apparatus in this embodiment during use, the bottom of the bracket 1 is fixed on the base 4, and the angle of the bracket 1 on the base 4 can be adjusted. In this way, when in use, the operator can place the first en...

Embodiment 2

[0054] See attached Figure 5 As shown, the slicing device in this embodiment is used to obtain paraffin slices, including a fixed base 17 and a specimen holder 18 and a blade 19 arranged on the fixed base 17, and the specimen holder 18 is vertically movable and arranged on the fixed base 17 , also includes the paraffin section transfer and display instrument in embodiment 1, the paraffin section transfer and display instrument is arranged under the specimen holder 18, the base 4 is fixed on the fixed seat 17, and the conveyor belt 7 is kept at an inclined angle to ensure that the conveyor belt 7. The first end is close to the blade 19, and can accept and absorb the paraffin wax slices cut off by the blade 19. When a paraffin block wrapped in biological tissue is placed in the specimen holder 18, the slicing device is started, and when the specimen holder 18 moves vertically downward for a predetermined distance, the edge of the paraffin block in the specimen holder 18 will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com