Wafer detection device, wafer transfer system and wafer detection method

A detection device, wafer technology, applied in the direction of semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of wafer detection errors, tilt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

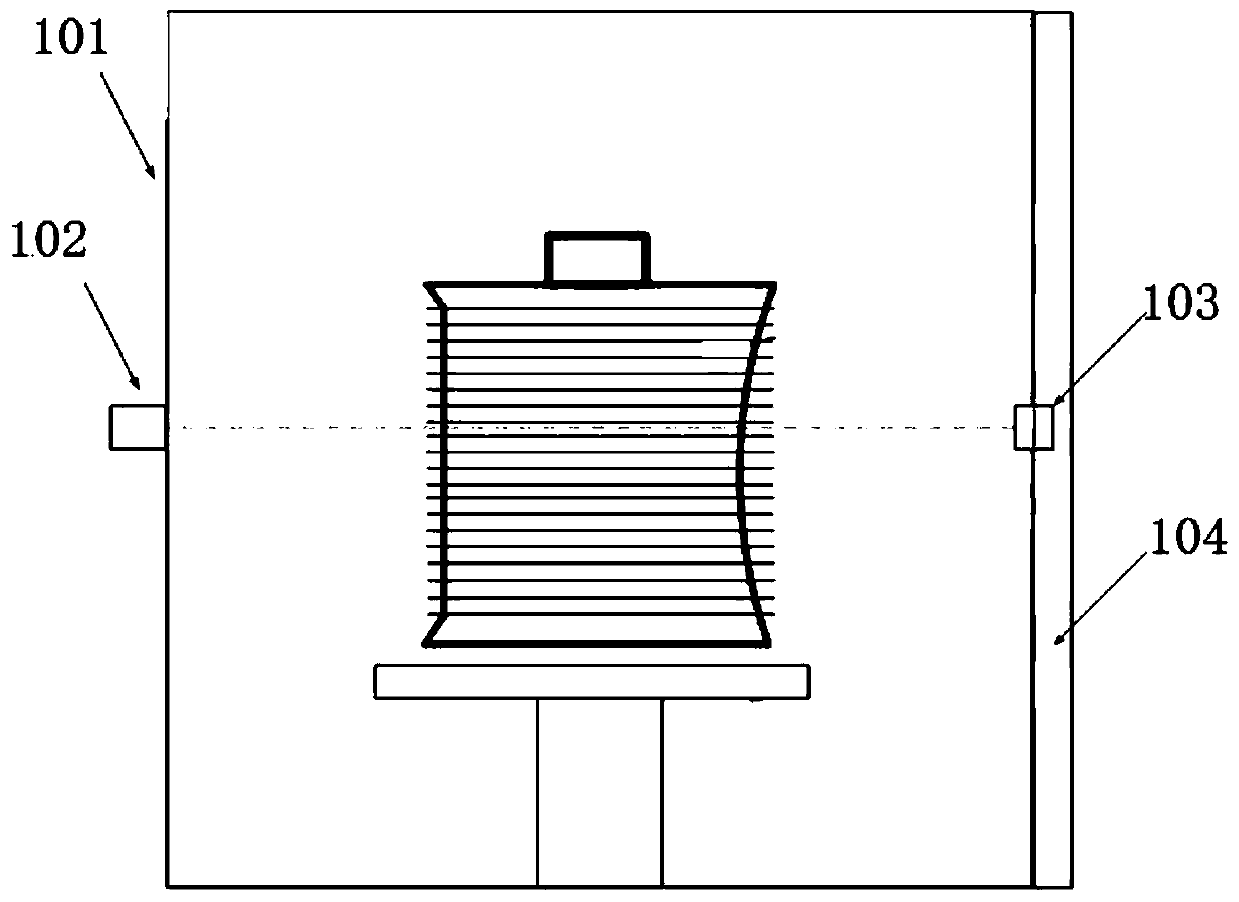

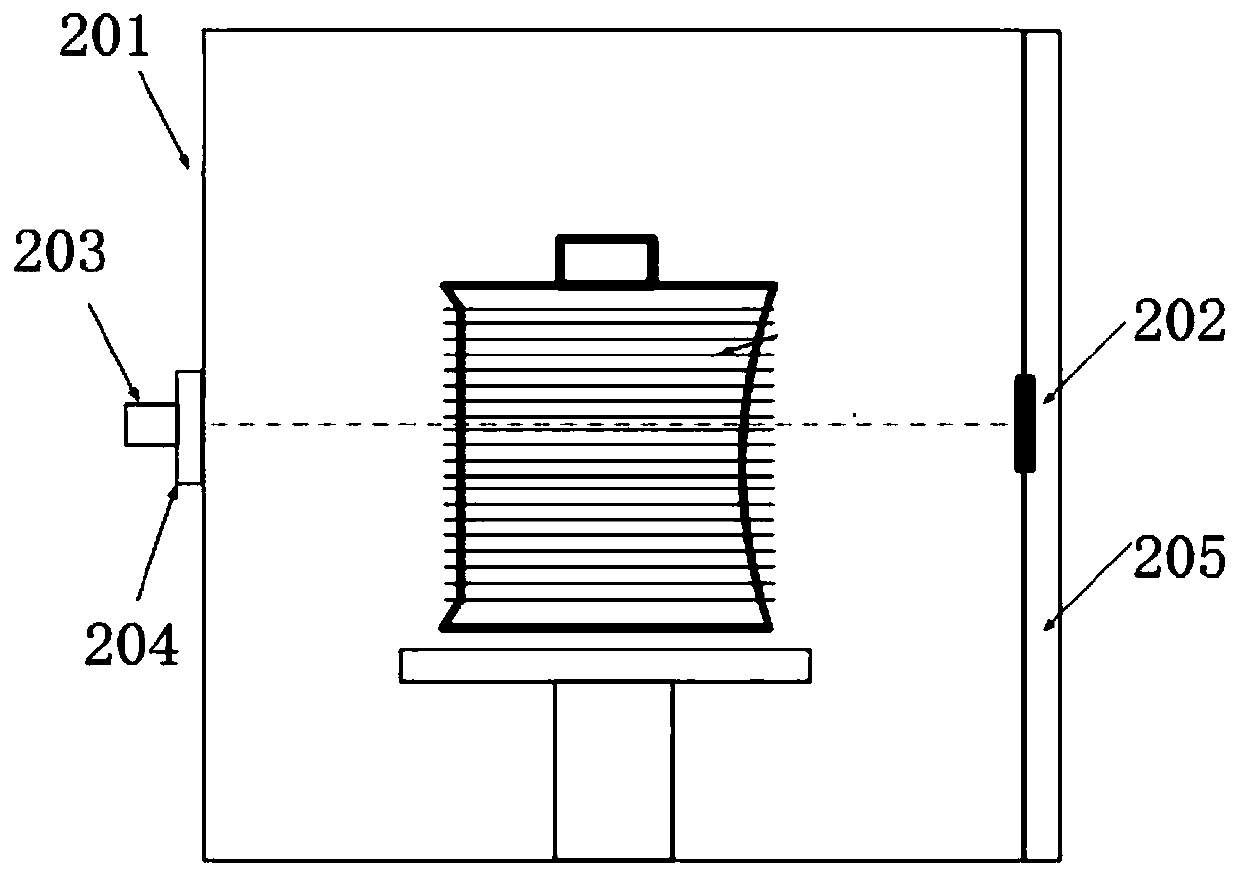

[0044] refer to figure 2 , which shows a schematic structural view of a wafer detection device described in Embodiment 1 of the present application. The wafer detection device is arranged on the loading chamber 201, and specifically includes:

[0045] Reflecting plate 202 , transceiver 203 and fixing plate 204 .

[0046] The fixing plate 204 is installed on the side wall of the loading chamber 201 , and the fixing plate 204 is provided with a light hole.

[0047] In practical applications, a wafer box may also be provided in the loading chamber, and the wafer box is used for placing wafers.

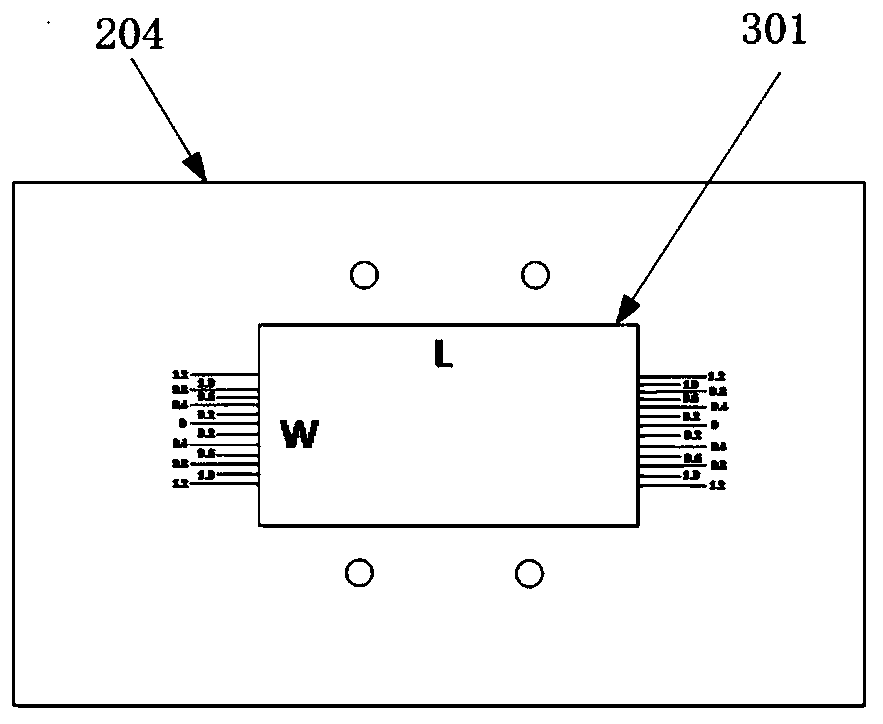

[0048] exist image 3 The figure shows the positions of the fixing plate 204 and the light hole 301. The light hole 301 is set at the middle position of the fixing plate 204, and can also be set at other positions, which is not specifically limited in this application.

[0049] The transceiver 203 is mounted on the fixing plate 204, and the transceiver 203 emits laser light into the l...

Embodiment 2

[0071] The present application also discloses a wafer transmission system, including the wafer detection device in the first embodiment.

[0072] And the loading chamber is also provided with a lifting platform and a servo motor.

[0073] Lift table for placing wafer cassettes.

[0074] The servo motor is used to control the movement of the lifting table according to the position of the wafer cassette.

[0075] In practical applications, the servo motor can be connected to the lifting platform through a rotating shaft, so that the servo motor can control the movement of the lifting platform according to the position information of the wafer cassette.

[0076] The wafer transmission system has all the advantages of the wafer inspection device in the first embodiment above, and will not be repeated here.

Embodiment 3

[0078] refer to Figure 7 , which shows a flow chart of a wafer detection method described in Embodiment 3 of the present application, the method is applied to a wafer transmission system, and specifically includes:

[0079] Step 701: loading the wafer into the loading chamber.

[0080] Step 702: The servo motor controls the wafer box of the lifting platform to be at the initial position of wafer detection.

[0081] Step 703: The transceiver emits laser light into the loading chamber through the light hole, and receives reflected light reflected by the reflector through the light hole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com