Liquid crystal composition and liquid crystal display device

A technology for liquid crystal display elements and liquid crystal compositions, which is applied in the directions of liquid crystal materials, instruments, chemical instruments and methods to achieve the effects of fast response speed, excellent low temperature storage stability, and high VHR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

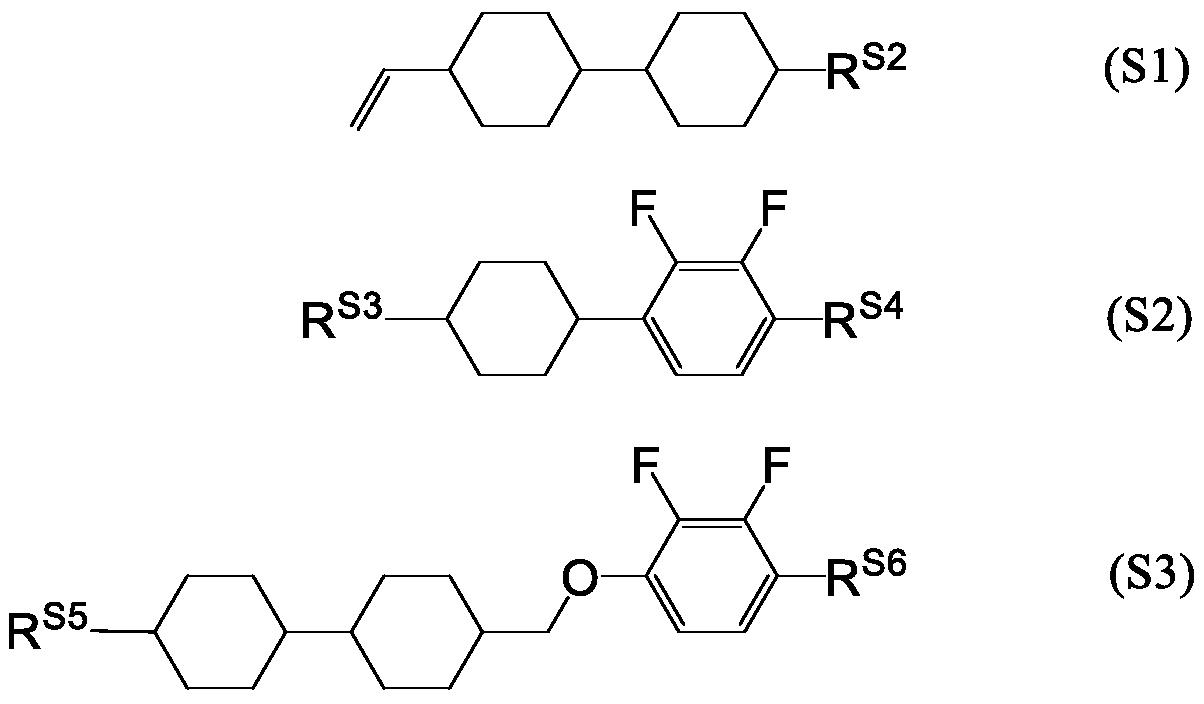

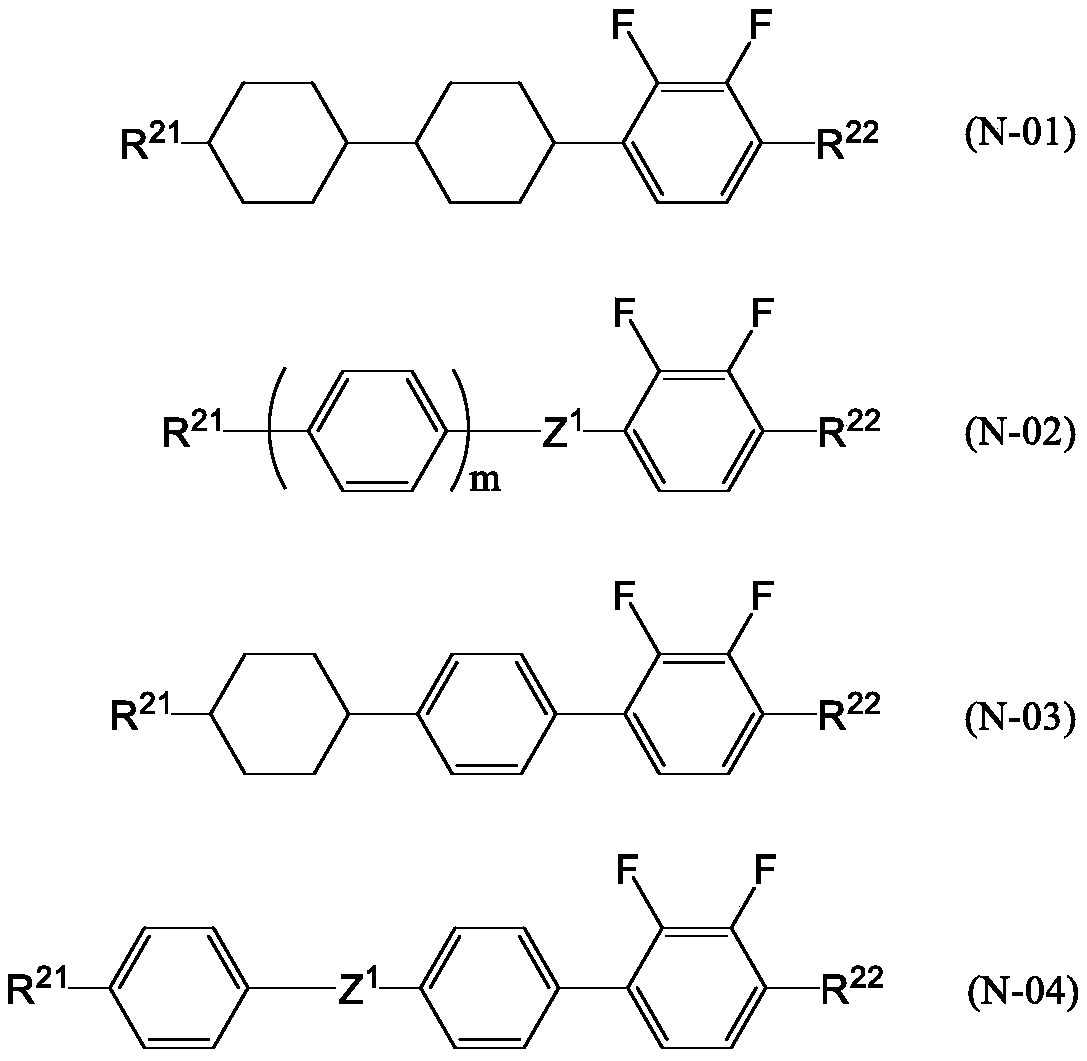

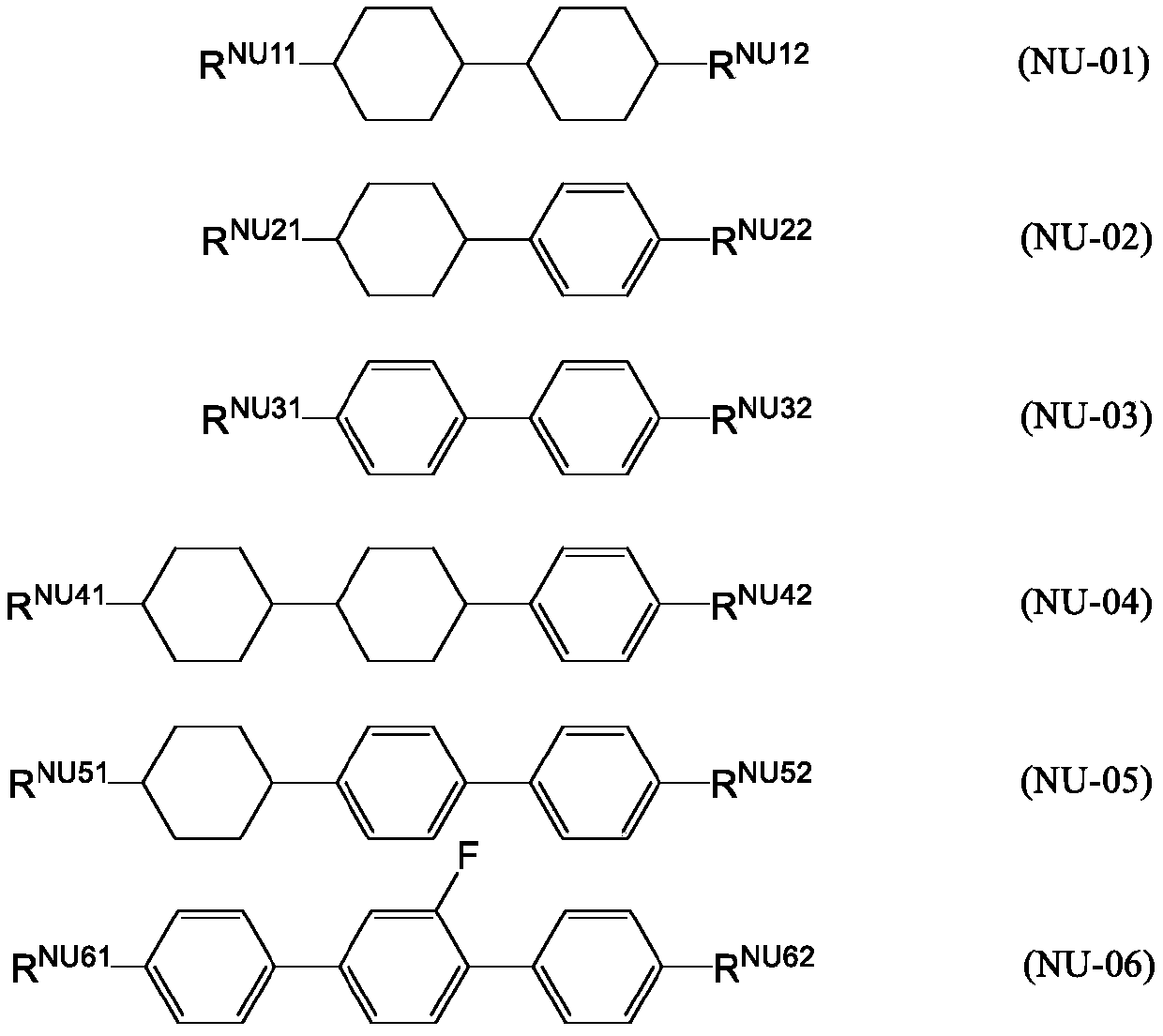

[0247] The following examples are given to further describe the present invention in detail, but the present invention is not limited to these examples. In addition, "%" in the composition of a following Example and a comparative example means "mass %". The following abbreviations are used for descriptions of compounds in Examples.

[0248] (side chain)

[0249] -n -C n h 2n+1 straight-chain alkyl group with carbon number n

[0250] n-C n h 2n+1 - Straight-chain alkyl group with carbon number n

[0251] -On -OC n h 2n+1 straight-chain alkoxy group with carbon number n

[0252] nO-C n h 2n+1 O- straight-chain alkoxy group with carbon number n

[0253] -V -CH=CH 2

[0254] V-CH 2 =CH-

[0255] -V1 -CH=CH-CH 3

[0256] 1V-CH 3 -CH=CH-

[0257] -F -F

[0258] -OCF3 -OCF 3

[0259] (link base)

[0260] -CF2O- -CF 2 -O-

[0261] -OCF2- -O-CF 2 -

[0262] -1O- -CH 2 -O-

[0263] -O1- -O-CH 2 -

[0264] -2- -CH 2 -CH 2 -

[0265] -COO- -COO-

[02...

preparation Embodiment 1

[0283] The liquid crystal compositions of Example 1 (LC-1), Comparative Example 1 (LC-A) and Comparative Example 2 (LC-B) were prepared, and their physical properties were measured. Table 1 shows the component ratios and physical property values of these liquid crystal compositions.

[0284] [Table 1]

[0285]

Embodiment 1

[0286] T of Example 1 (LC-1) NI High, T CN Low, so the temperature range of the nematic phase is wider, Δn is larger, Δε is negative and its absolute value is larger, γ 1 Smaller, K 11 Larger, K 33 Larger, responsiveness-related γ 1 / K 33 smaller. FFS-type and VA-type liquid crystal display elements obtained using the same were produced, and it was confirmed that fast response speed, high VHR, and excellent low-temperature storage stability were compatible, and that there was no display defect. That is, the liquid crystal composition of Example 1 (LC-1) was excellent in each physical property, and solved the subject of this invention.

[0287] On the other hand, using the FFS-type and VA-type liquid crystal display elements produced in Comparative Example 1 (LC-A), it was confirmed that the response speed was significantly slower, about 15% slower than that of Example 1 (LC-1). % responsiveness. In addition, the VHR of Comparative Example 1 (LC-A) was a very low value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com