Mixing device for potassium chlorate production

A technology of mixing device and potassium chlorate, which is applied to mixers with rotating stirring devices, mixers, transportation and packaging, etc., can solve the problems affecting the production efficiency of potassium chlorate and low feeding speed, and achieve good fixing effect and increase Productivity, effect of reducing cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

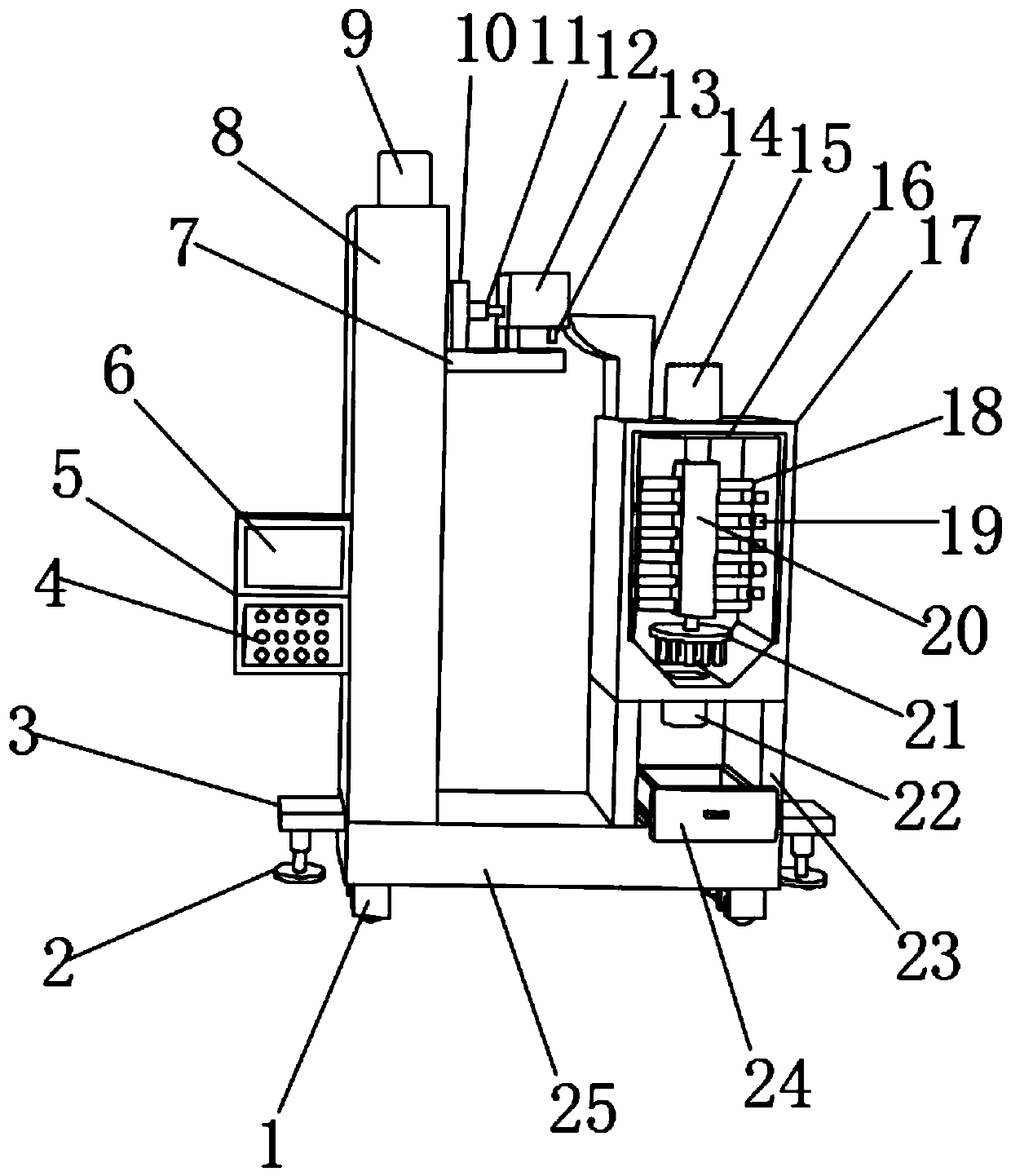

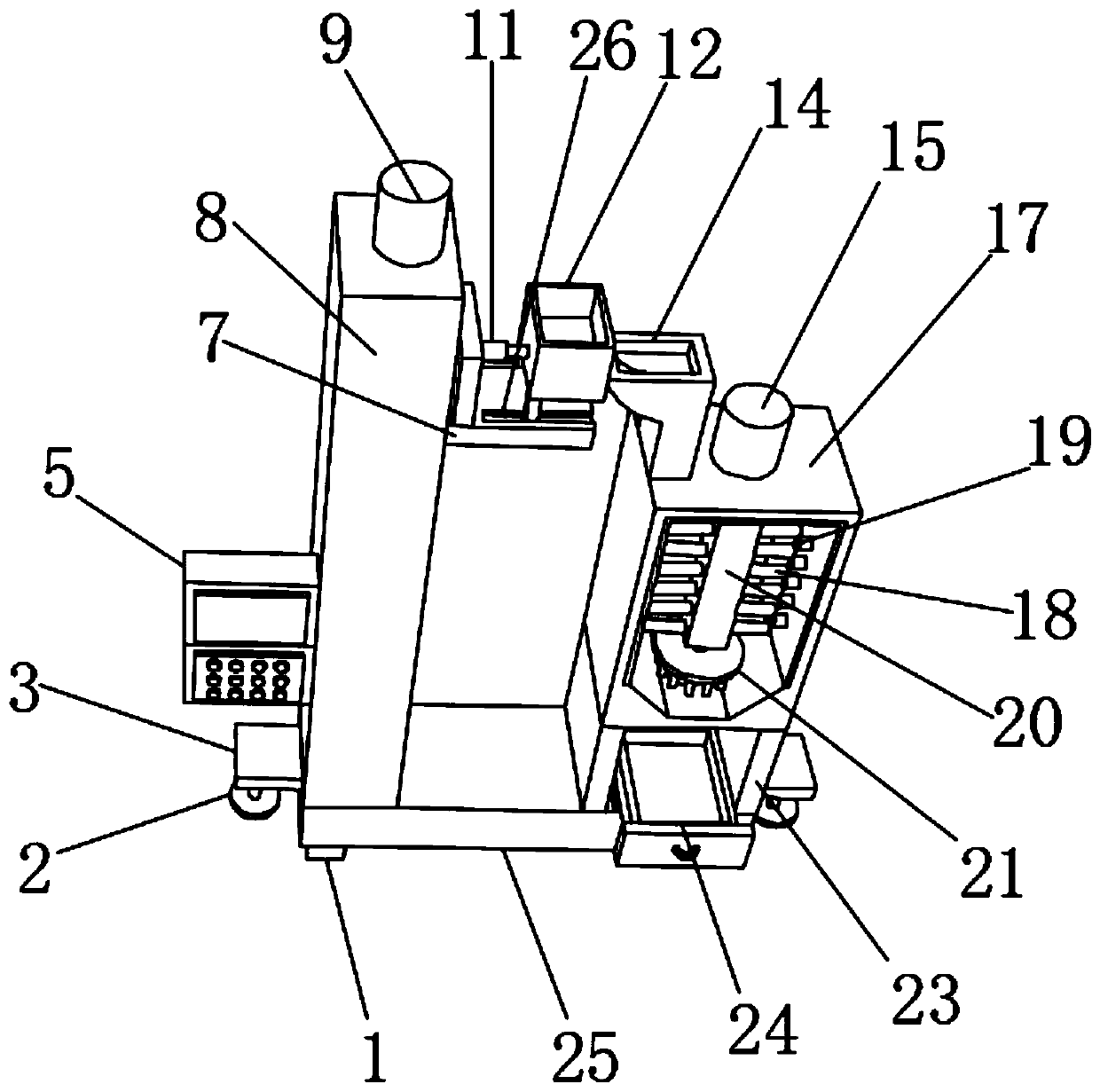

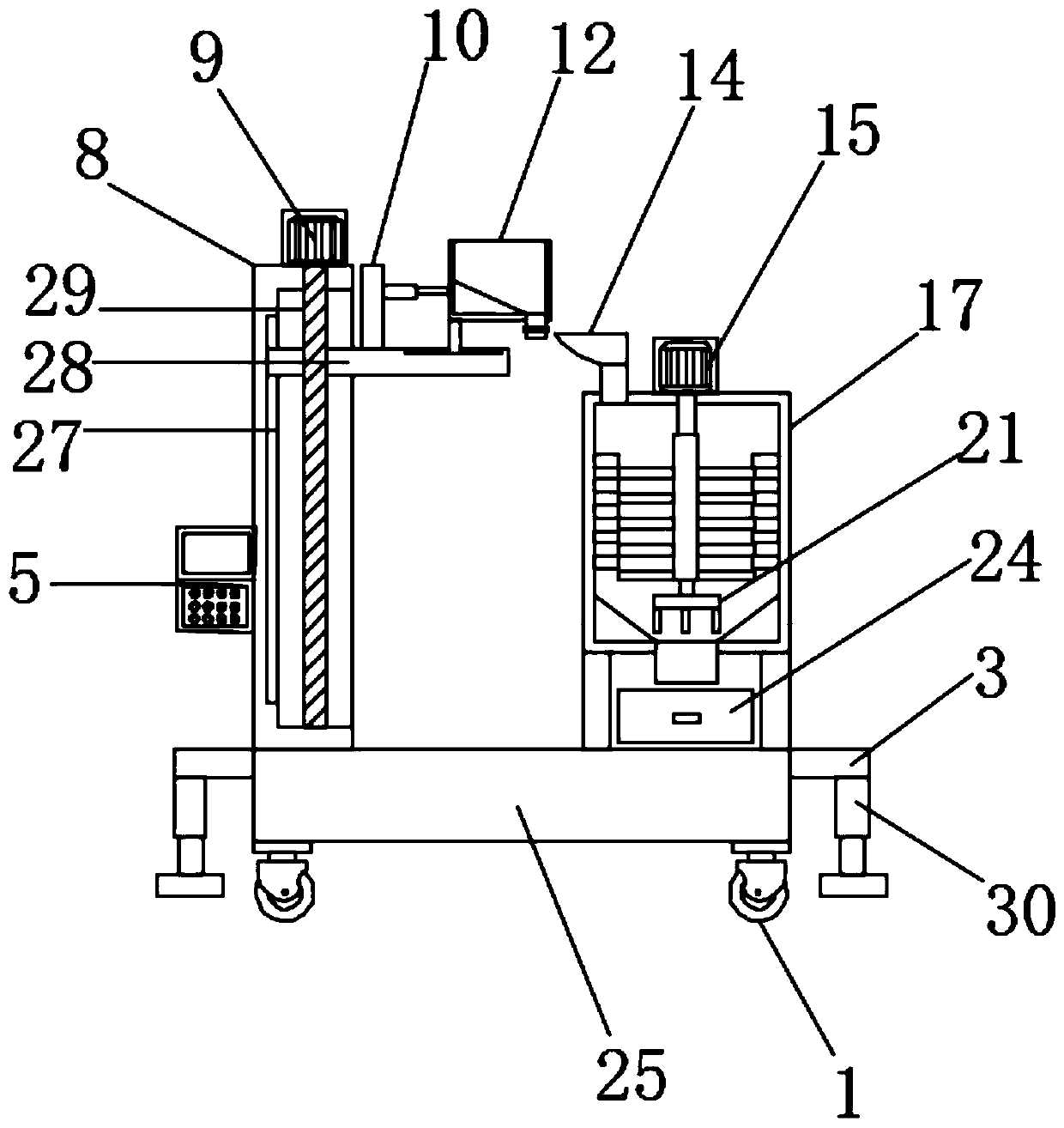

[0028] A kind of mixing device for potassium chlorate production, such as Figure 1-4 As shown, including the base 25, one side of the outer wall of the top of the base 25 is fixed with a support column 8 by screws, and one side of the outer wall of the support column 8 is provided with a groove, and the top outer wall of the support column 8 is fixed with a servo motor 9 by screws, and The output shaft of the servo motor 9 is connected with a screw mandrel 29 through a shaft coupling, the outer wall of the screw mandrel 29 is sleeved with a collar 28, and one side outer wall of the collar 28 is fixed with a moving plate 7 by screws, and the top outer wall of the moving plate 7 A chute 26 is provided, and the inwall of the chute 26 is slidably connected with a sliding column, the top of the sliding column is fixed with a feeding chute 12 by screws, and the bottom outer wall of the feeding chute 12 is provided with a feeding hole, and the inner wall of the feeding hole A feedin...

Embodiment 2

[0037] A kind of mixing device for potassium chlorate production, such as image 3 As shown, in order to solve the problem of stability in the mixing process; this embodiment makes the following improvements on the basis of embodiment 1: the outer walls on both sides of the base 25 are fixed with connecting plates 3 by screws, and the bottom outer walls of the connecting plates 3 pass through The screw is fixed with a hydraulic rod 30, and one end of the piston rod of the hydraulic rod 30 is fixed with a support plate 2 by a screw.

[0038] When this embodiment is in use, the hydraulic rod 30 is controlled to elongate the piston rod, and the support plate 2 contacts the ground to fix the device, which has a good fixing effect and improves the stability of the device during operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com