Cab top cap sealing installation structure and all-terrain vehicle comprising same

A roof sealing and installation structure technology, which is applied to the connection between the superstructure sub-assemblies, the superstructure, the superstructure sub-assembly, etc., can solve the problems of drivers and passengers, not easy to bake or rain, Rainwater entering the car and other problems, to achieve the effect of improving assembly efficiency, convenient and fast installation, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

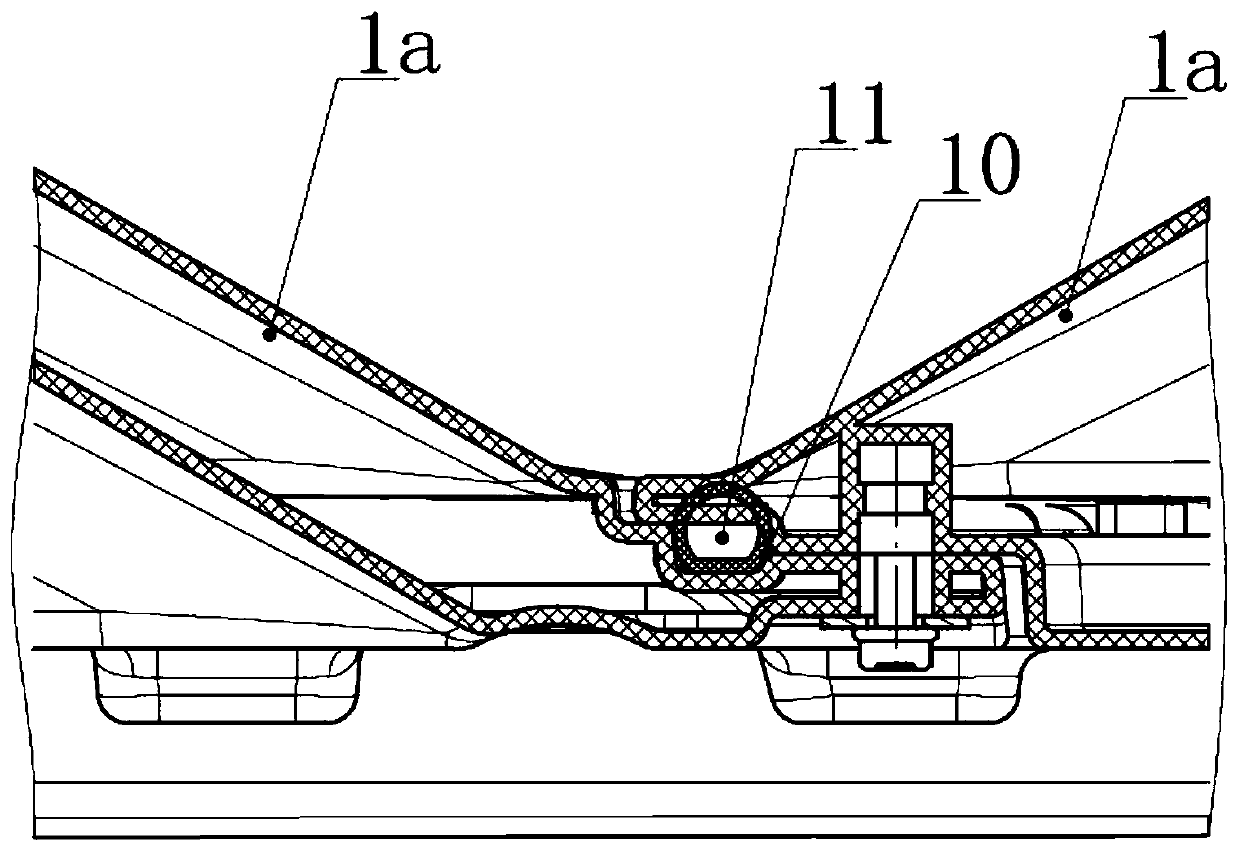

[0033] figure 1 Shows a cab roof sealing installation structure provided by the present invention, a frame 3 and a roof 1 mounted on the frame 3, the roof 1 includes a plurality of sequentially overlapping unit panels 1a, and The overlap between the two adjacent unit plates 1a has a sealing structure. Specifically, the inner surface of the overlapping end of the previous unit plate 1a has countersunk screw holes, and the overlapping end of the latter unit plate 1a has fixing holes corresponding to the countersunk screw holes, and two adjacent unit plates 1a are overlapped. Then, the two adjacent unit boards 1a are fixed and installed by screwing and fixing, which not only facilitates the installation of the top cover 1, but also makes the removal of the top cover 1 more convenient; at the same time, by installing the screws from the car, it effectively prevents the screw installation Leaking.

[0034] By providing a sealing structure at the overlap of two adjacent unit plates 1a...

Embodiment 2

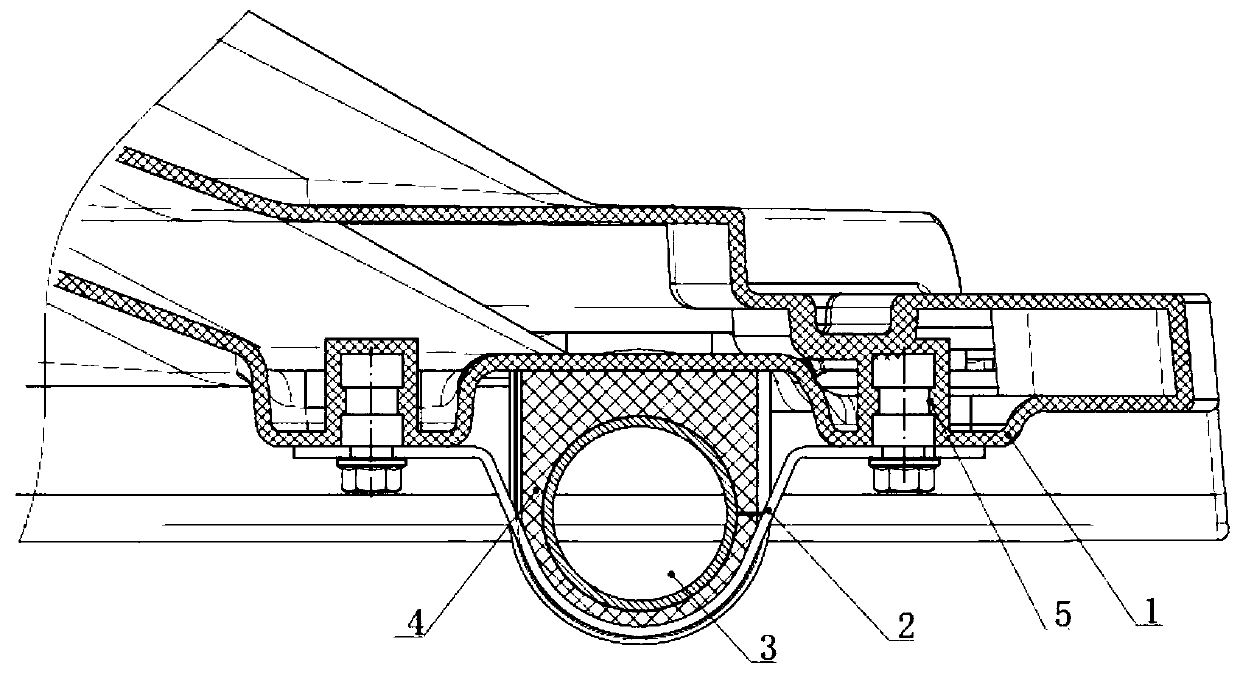

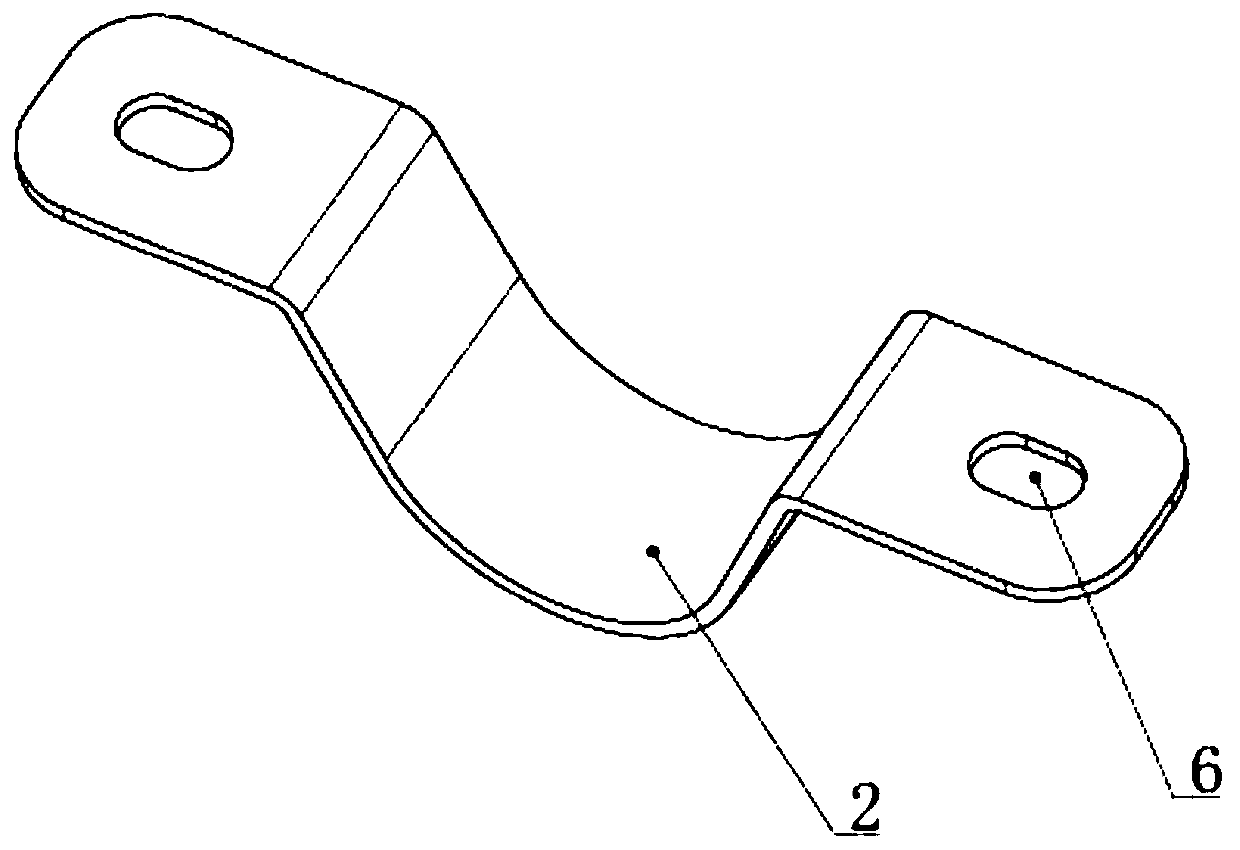

[0039] Such as figure 2 , image 3 As shown, this embodiment provides an automobile roof mounting structure. In this second embodiment, on the basis of the first embodiment, the roof 1 is fixedly installed on the frame 3 through the hoop 2. The top cover 1 is blow-molded, and inwardly recessed screw holes 5 can be provided on the inner surface of the top cover 1 during the molding process of the top cover 1. The hoop 2 is hugged on the frame 3, and both ends of the hoop 2 are fixedly installed on the inner wall of the top cover 1 by screws. By using the hoop 2 to fix the top cover 1 and the frame 3, the frame 3 does not need to be processed on the frame 3 with screw mounting holes precisely corresponding to the screw holes 5 during processing, and the processing efficiency of the frame 3 is greatly improved. At the same time, by using the hoop 2 to fix the top cover 1 and the frame 3, because the hoop 2 has a small structure, the staff can quickly find the hoop 2 and screws wh...

Embodiment 3

[0045] Such as Figure 4 As shown, this embodiment provides a car roof mounting structure. On the basis of Embodiment 2, this embodiment 3 also includes a windshield 7 fixedly installed on the frame 3, and the upper end of the windshield 7 is embedded in On the inner surface of the top cover 1. The windshield 7 is fixedly installed on the frame 3 obliquely, and the upper end of the windshield 7 is embedded on the inner surface of the top cover 1, so that the top cover 1 can protect the installation location of the upper end of the windshield 7. It effectively prevents rainwater from entering the car directly through the gap between the windshield 7 and the roof 1 during the forwarding process; at the same time, when the roof 1 is installed, due to the fixed installation of the roof 1, make the roof 1 pair The windshield 7 exerts a pressing force, and the upper end of the windshield 7 is pressed and fixed with the top cover 1, so that the fixing and installation of the windshiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com