Adaptive continuously-adjustable cavitation device structure

An adaptive cavitator technology, applied in ships, special-purpose ships, underwater ships, etc., can solve problems such as the mismatch between the shape of the supercavitation and the shape of the sailing body, poor cavitation stability, and large overall resistance. The effect of continuous change satisfaction, reduction of frictional resistance, and reduction of total resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

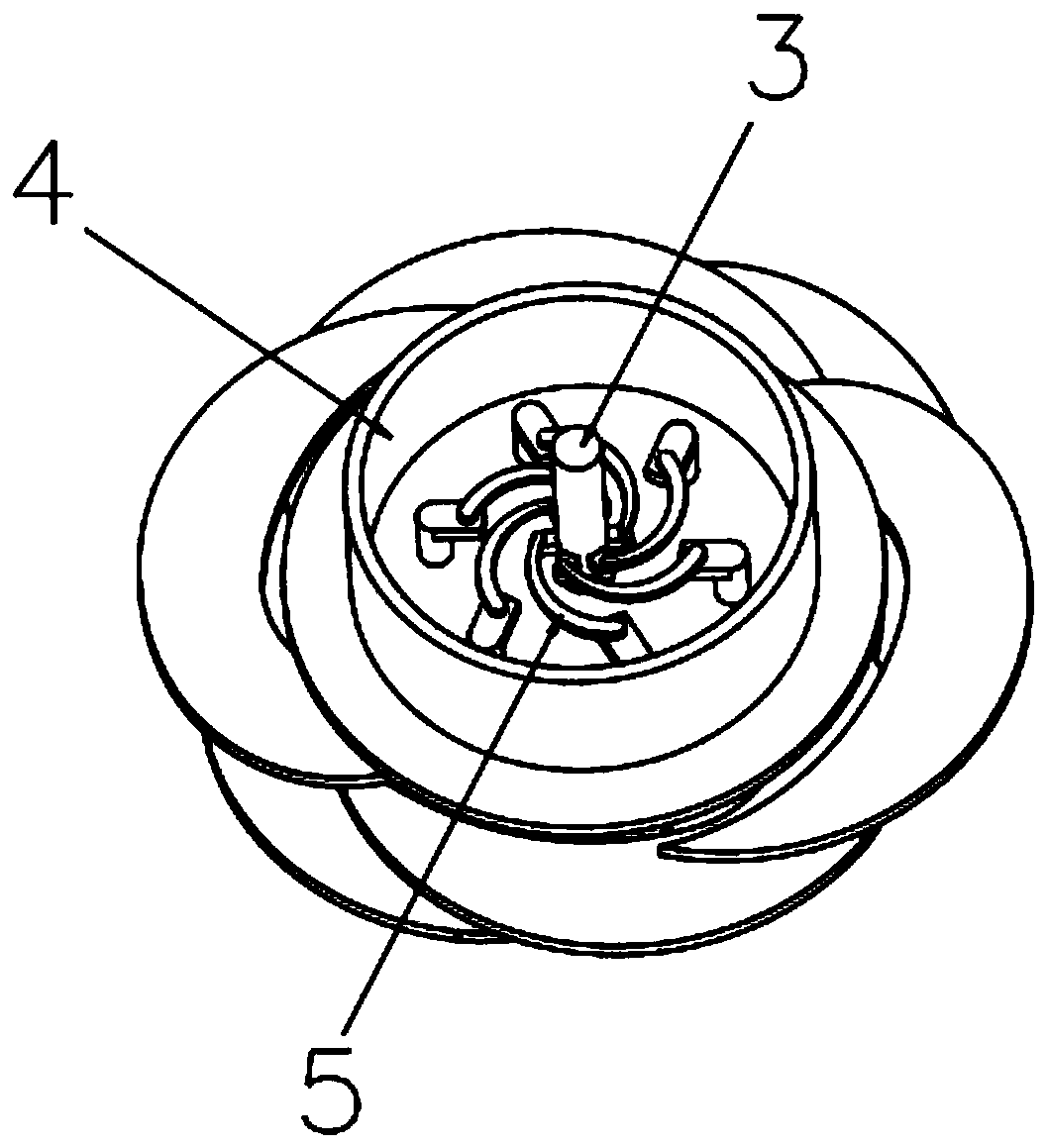

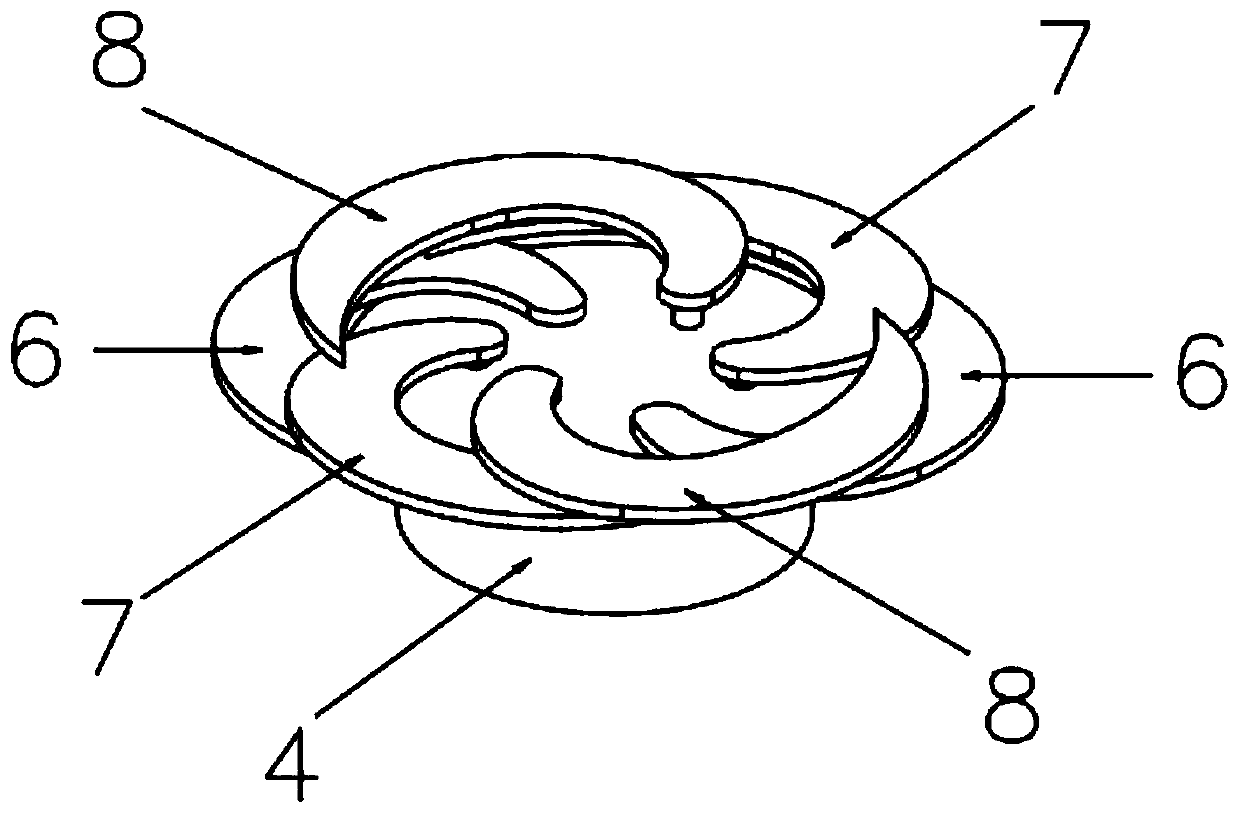

[0054] as attached Figure 2-Figure 4 An adaptive and continuously adjustable cavitator structure shown includes a reference chassis 4 connected to each other, a rotatable telescopic component and a drive mechanism component, wherein,

[0055] The reference chassis 4 is installed between the rotatable telescopic part and the drive mechanism part, the geometric center of the reference chassis 4 is fixedly connected to the drive mechanism part, and the outer surface is in contact with the innermost surface of the rotatable telescopic part; In this embodiment, the reference chassis 4 has a circular shape, also called a reference disk.

[0056] In another embodiment of the present invention, the shape of the reference chassis is conical or concave cone-shaped.

[0057] The rotatable telescopic component includes three layers of fan-shaped groups that can move synchronously inward / outward. Each layer of the fan-shaped group is respectively connected to the drive link 5, and the ot...

Embodiment 2

[0078] as attached Figure 2-Figure 9 The self-adaptive and continuously adjustable cavitator structure shown includes a reference chassis 4 connected to each other, a rotatable telescopic part and a drive mechanism part. The difference from Embodiment 1 is that the rotatable telescopic part includes n layers A set of sectors that are cross-mounted on the reference chassis 4 and can move synchronously inwardly / outwardly, where n is an integer greater than 3; the process and principle of use are the same as those in Embodiment 1.

Embodiment 3

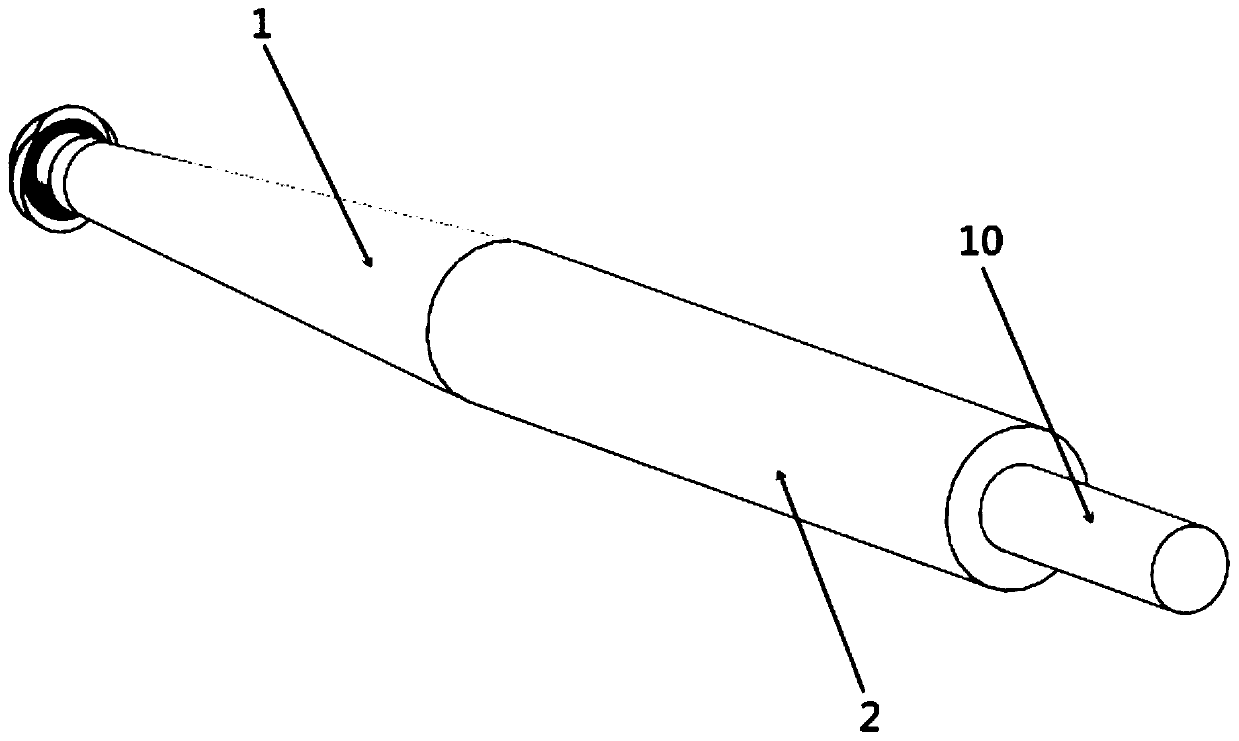

[0080] as attached figure 1 As shown in the underwater vehicle, the present invention also provides an underwater vehicle on the basis of Embodiment 1 or Embodiment 2, including the main body of the vehicle and the self-adaptive continuously adjustable The cavitator structure, the self-adaptive continuously adjustable cavitator structure is fixedly connected to the main body of the vehicle by welding, screwing or bonding, and the aircraft is coaxial with the reference chassis 4 .

[0081] Specifically, the main body of the navigation body includes a conical body 1 that is docked with the reference chassis 4 at one end and a cylindrical body 2 that is fixedly connected to the other end of the conical body 1. The cylindrical body 2 is far away from the One end of the conical projectile 1 is fixedly connected to the nozzle 10 of the navigation body; the reference chassis 4 is rigidly connected to the conical projectile 1; in this embodiment, the cylindrical body 2 is cylindrical;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com